How Does an Ultrasonic Flow Meter Work?

What is an ultrasonic flow meter?

The ultrasonic flowmeter is the "velocity difference method" as the principle, measuring the flow of liquid in a circular tube instrument. It adopts advanced multi-pulse technology, signal digital processing technology, and error correction technology so that the flow meter can better adapt to the industrial site environment, and measurement more convenient, economic, and accurate. The product has reached the advanced level at home and abroad and can be widely used in petroleum, chemical, metallurgy, electric power, water supply and drainage, and other fields.

Ultrasonic flow meter working principle

When the ultrasonic signal is reflected by suspended particles or bubbles (discontinuities) in motion, the basic operating principle utilizes the frequency shift of the ultrasonic signal (Doppler effect). This metrology technique takes advantage of the physical phenomenon of sound waves, which change frequency when it is reflected by a moving discontinuity in a flowing liquid. The ultrasound is transmitted into a pipe with a flowing liquid and the discontinuity reflects a slightly different frequency of ultrasound, which is proportional to the flow rate of the liquid. Current technology requires liquids containing at least 100 parts per million (PPM) of suspended particles or air bubbles of 100 microns or larger.

The Doppler ultrasonic flowmeter works on the principle of the Doppler effect, which is the physical phenomenon of a change in the frequency of sound waves. In the case of ultrasonic flow meters, when reflected by suspended particles or bubbles in motion (discontinuity), the frequency change of the ultrasonic signal (Doppler effect) is proportional to the flow rate of the liquid.

Typically, an ultrasonic Doppler flowmeter consists of a transmitter/indicator/accumulator and a transducer. The user selects the configuration appropriate for the application, taking into account the size and concentration of the liquid, solids, or bubbles, pipe size, and pipelining. The transmitter's signal threshold is typically adjusted to filter out mechanical and electrical noise.

A high-frequency oscillator in the transmitter drives the transducer, which is mounted on the outside of the pipe in a popular clamp-on design. The transducer generates an ultrasonic signal that passes through the pipe wall into the flowing liquid; the transmitter converts the difference between its output and input frequencies into electronic pulses. After processing, scaling, and accumulation, the pulses provide the flow measurement.

Ultrasonic Doppler flow meters clamped to the outside of the pipe operate in a non-intrusive manner, eliminating the need for moving parts. They cause no pressure drop, are not subject to the risk of process fluid damage and require little or no maintenance. When properly calibrated, they can achieve an accuracy of ±1%, however, the pipe wall and any air space between the pipe wall and the liquid can create signal interference. In addition, the stainless steel tube wall may conduct the transmission signal to the extent that the reflected signal appears to change significantly.

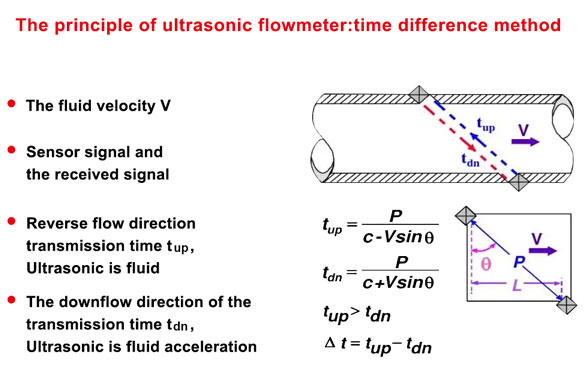

The transmission time ultrasonic flowmeter measures the time difference between the ultrasonic signal being transmitted from the first transducer and received by the second transducer. Comparisons are made between upstream and downstream measurements. If there is no flow, the travel time will be the same in both directions. When there is flow, sound travels faster when it travels in the same direction, and slower if it travels against it.

Ultrasonic flow meters use a mutual correlation between upstream and downstream transducer pairs to calculate the flow rate. Some flowmeters of this design use a microprocessor to automatically switch between "clean" and "dirty" modes based on relevant factors. For example, a single interdependent hybrid flow meter can monitor the flow of activated sludge or digested sludge. Well-designed applications using such flowmeters have reported installation accuracies within 0.5% of reading.

Ultrasonic flowmeter advantages

The ultrasonic flowmeter is a non-contact instrument, it can measure the flow of large pipe diameter media and can also be used for the measurement of media that are not easily accessible and observable. Its measurement accuracy is very high, external clamping installation can also reach a maximum accuracy of ± 0.5%, almost immune to the interference of various parameters of the measured medium, especially other instruments can not solve the problem of strong corrosive, non-conductive, radioactive and flammable and explosive media flow measurement.

Ultrasonic flowmeter disadvantages

The disadvantages that exist today are mainly the temperature range of the measurable fluid is limited by the temperature resistance of the ultrasonic transducer aluminum and the coupling material between the transducer and the pipe, as well as the high temperature of the measured fluid acoustic velocity of the original data is incomplete.

ATO portable ultrasonic flowmeter has accurate readings, a built-in large-capacity data recorder is battery-powered, and can work for a long time. It is suitable for all kinds of pure liquids, including water, tap water, seawater, beer, lubricating oil, gasoline, edible oil, etc. ATO.com offers you a variety of flow meters including magnetic flow meters, vortex flow meters, turbine flow meters, portable ultrasonic flow meters, and small gas mass flow meters.