How does PLC Read Data of Load Cell Transmitter?

A load cell is a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cell used are strain gauges, pneumatic, and hydraulic.

Today we will show you how PLC read data of the load cell transmitter by using ATO load cell and ATO PLC.

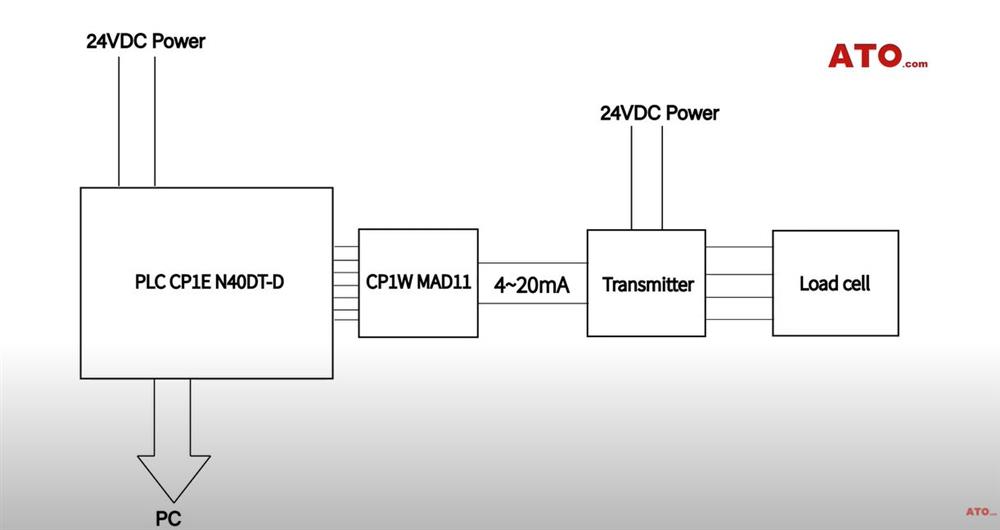

A system is mainly divided into several parts: PLC control system (here is Omron's PLC +analog reading module), load cell transmitter (converts the load cell signal to 4-20mA), load cell, power supply system and monitoring system PLC (upper computer).

Wiring of PLC and load cell

Wiring diagram

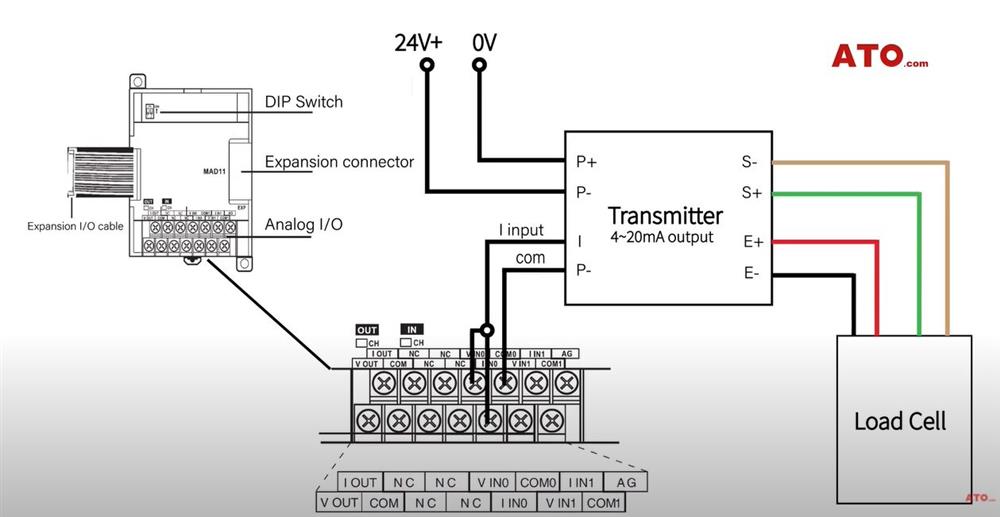

Connection of OMRON MAD11 module with ATO load cell transmitter and ATO load cell. There are two wires of the transmitter's output analog quantity. Before connection to MAD11, we must make sure that its output is correct.

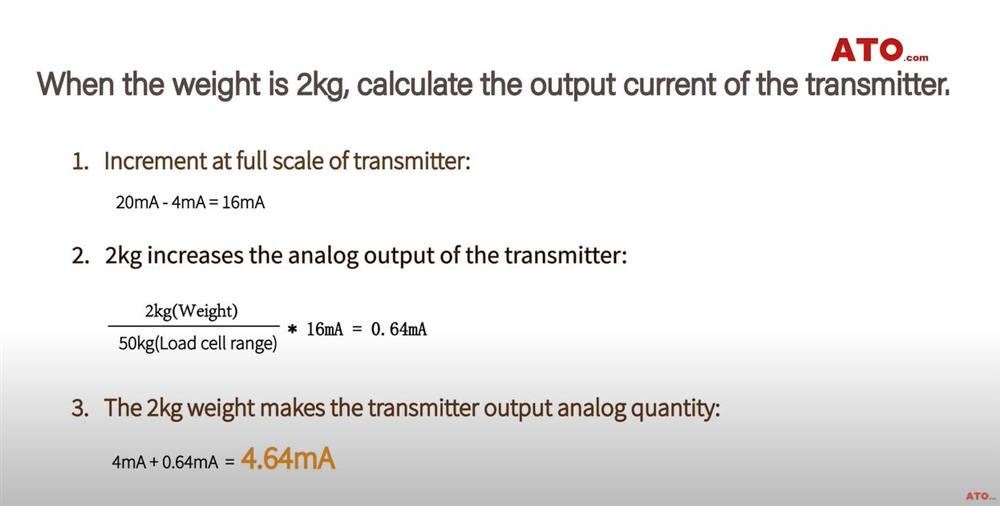

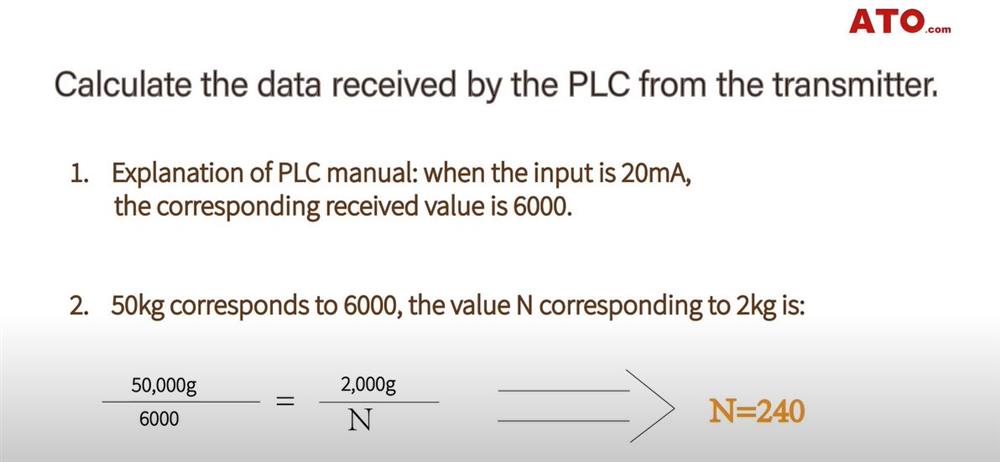

The above is the calculation method of the transmitter output 4-20mA analog quantity (rated load cell of 50kg, and 2kg weight). It is concluded that the transmitter should output 4.64mA.

When the load cell has no load, the output analog quantity is 4mA. Put a 2kg weight on the sensor, the transmitter output 4.65mA (A slight error is normal)

This is Omron's PLC and analog module MAD11, According to the MAD11 manual,VIN0 and lINO (V IN1 and l lN1) should be short-circuited when using current input. There is an average value dial switch on the upper part.

The connection of the entire system is completed, and the PLC has been connected to the PC.

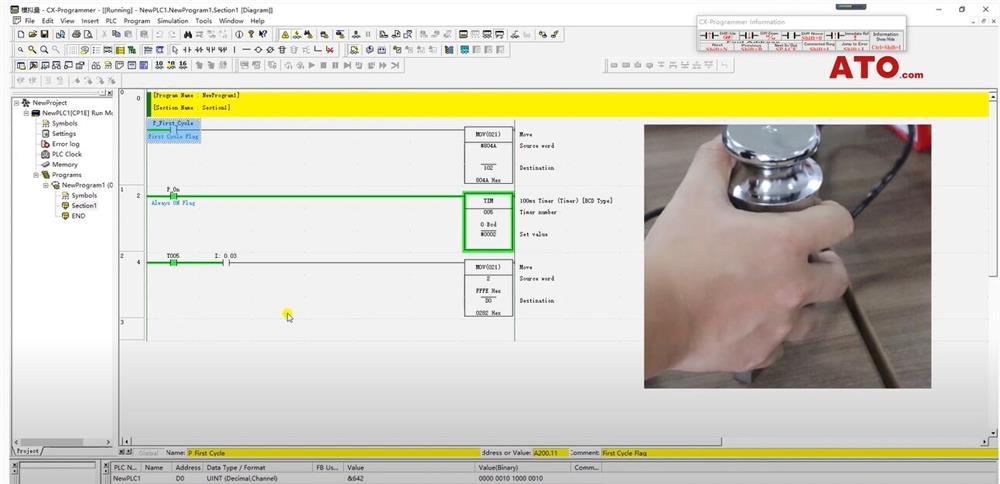

Program for PLC to read data

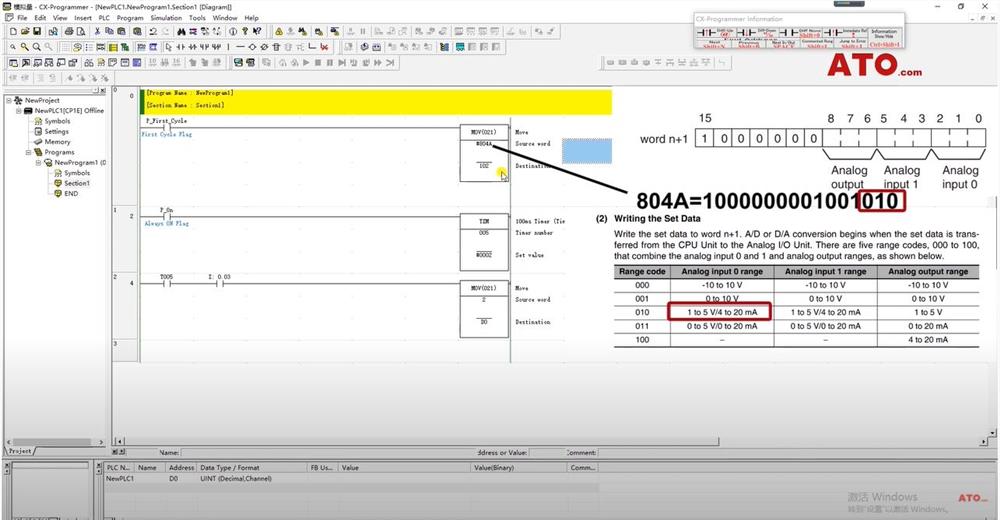

This is a program for PLC to read data.

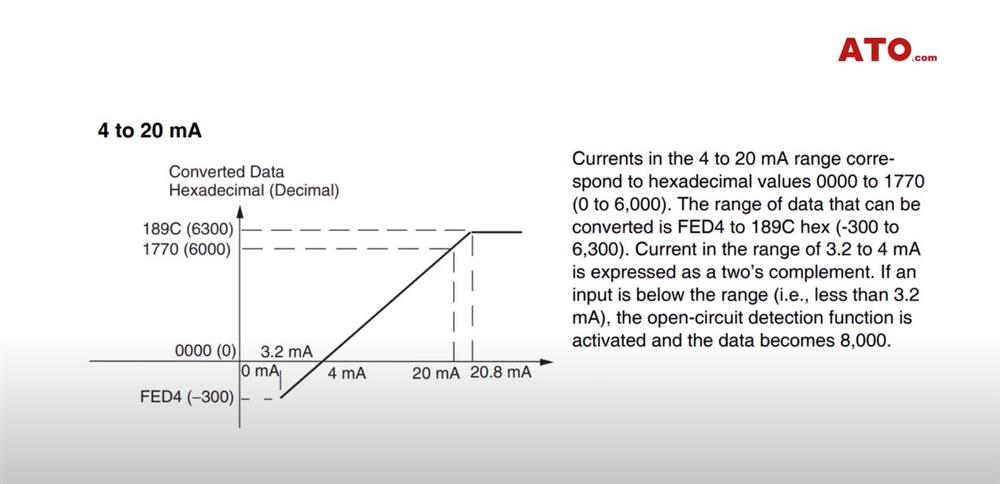

We monitor the storage area D0 to know the load change of the load cell. PLC data corresponding to 4-20mA.

From the calculation, when the load is 2kg, the data read by the PLC should be 240.

PC connects PLC to monitor real-time data. The ATO load cell transmitter transmits to the PLC the data close to 0 (FFFF~0000) under no load.

Put on the 2kg weight and turn on the external button l0.03, the data will be transmitted to D0.

The decimal display value of D0 is 241. We can also switch to hexadecimal data view. Change the load of the load cell, the data read by D0 changes. Therefore, we can calculate the current load weight based on the read data.

See more details by checking the video below.