How to Install Quick Connectors?

Quick connectors are convenient, fast, and reliable electrical connection devices widely used in home circuits, automotive electrical systems, industrial automation, and other fields. Quick connectors not only save time but also reduce the risk of wiring errors. In this article, ATO.com will introduce how to install quick connectors, including preparation work, wiring steps, and things to pay attention to.

Preparation

Before installing a quick connector, make sure you have done the following preparations.

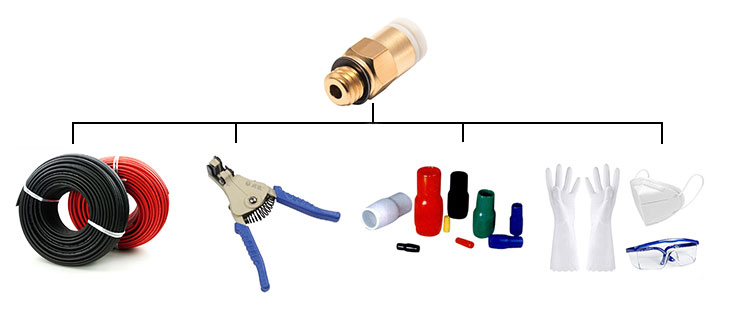

Tools and Materials

- Quick Connector: Choose the right model and specification according to the need.

- Wires: Make sure the length and specification of the wires meet the requirements.

- Wire Strippers: For removing wire insulation.

- Insulation Sleeve: To protect the connection part.

- Gloves and Goggles: To ensure personal safety.

- Safety Measures: Before starting work, make sure you have taken the proper safety measures, including disconnecting the power supply, disconnecting the electrical circuit, and wearing goggles and gloves. Electrical work requires caution and attention to safety to avoid injury or electric shock.

Wiring Procedures

- Disconnect Power: Make sure the power is disconnected before performing any electrical connection work. Turn off the main circuit breaker or circuit switch to prevent current from flowing through the circuit.

- Select the Appropriate Connector: Select the appropriate type and size of quick connectors for your needs. Different applications may require different types and capacities of connectors. Make sure the selected connector is suitable for your circuit.

- Strip Wire Insulation: Use wire strippers to carefully remove insulation from the ends of wires. Make sure the length of insulation you strip meets the requirements of the connector. Usually, the connector's packaging will have instructions for this.

- Insert the Wire: Insert the stripped wire into the appropriate slot of the quick connector. Make sure the wires are fully inserted with good contact and no exposed wires.

- Fasten the Connector: Use screws, snaps, or other mechanical devices to fasten the connector, depending on the design of the connector. Make sure that the connector is securely fastened and that the wires do not come loose.

- Protecting Insulation: Use an insulating sleeve to cover the connection section to protect the wires and connectors. This helps prevent short circuits between the wires and damage to the insulation.

- Check The Connection: Once the connector is installed, double-check the connection to make sure everything is in order. Make sure there are no loose wires or connector sections.

- Re-energize: After confirming that everything is in order, re-energize the power and turn on the main circuit breaker or circuit switch. Make sure the circuit is operating properly and that there are no shorts or other problems.

Caution

Always prioritize safety. Disconnect power, wear goggles and gloves, and ensure a safe working environment. Follow the manufacturer's guidelines, different quick connectors may have different installation guidelines and requirements. Always read and follow the manufacturer's guidelines to ensure proper installation. Ensure wire quality, use high-quality wires, and make sure wire ends are clean and free of oxidation. Low-quality wires may result in poor connections. Do not over-tighten connectors as this may damage the wire or connector section. Tighten according to the manufacturer's recommendations.

Periodically check for loose or damaged connections. Loose connections can lead to circuit failure or hazards. Make sure the selected connector is appropriate for your application. Different applications may require different types of connectors, such as power connectors, RF connectors, automotive connectors, and so on. If you have more than one connector to install, make sure you don't mix them up. Mark or record the location and purpose of the connections to avoid confusion or misconnections. Finally, make sure your installation complies with local electrical codes and regulations. If you're not sure, it's best to hire a professional electrician to do the installation.

Installing quick connectors is a relatively simple task, but requires care to ensure a safe and reliable connection. Following the steps and precautions outlined above can help you successfully install connectors, whether in-home electrical, industrial automation or other applications. Proper installation of connectors helps ensure proper operation of equipment and reduces the need for maintenance and repairs. If you are unsure how to install a connector or have special requirements, consult a professional electrician or technical support at the ATO shop.