PLC Selection Guide

Programmable Logic Controller referred to as PC or PLC is an electronic system operated by digital operations, specially designed for application in an industrial environment. It uses a memory that can be programmed to execute instructions for storing logical operations and sequence control, timing, counting and arithmetic operations, and through digital or analog input (I) and output (O) interfaces, controls various Type of mechanical equipment or production process. PLC is developed on the basis of electrical control technology and computer technology, and gradually developed into a new type of industrial control device with microprocessor as the core and integrating automation technology, computer technology and communication technology. PLC has been widely used in the automatic control of various production machinery and production processes. It has become one of the most important, popular, and most used industrial control devices, and recognized as one of the three pillars of modern industrial automation (PLC, robot, CAD/CAM).so what details do we need to know when choosing a PLC?

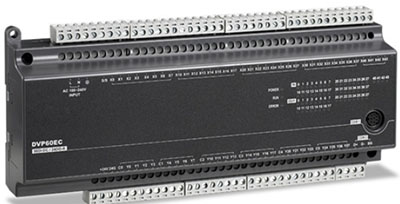

PLC type

it is divided into two types according to the structure: integral type and module type. When classified by the application environment, it is divided into another two types: on-site installation and control room installation; according to the word length of the CPU, it is divided into 1 bit, 4bit, 8bit, 16bit, 32bit, 64bit Wait. From the application point of view, it can usually be selected according to the control function or the number of input and output points. The integral PLC has a fixed number of I/O points, so the user has less choice; modular PLCs provide a variety of I/O cards or plug-in cards, so users can select and configure the control system more reasonably, the number of I/O points and the function expansion are convenient and flexible, and it is generally used in large and medium-sized control systems.

Selection of input and output modules

The selection of input and output modules should consider the unity of application requirements. For example, for input modules, application requirements such as signal level, signal transmission distance, signal isolation, and signal power supply mode should be considered. For the output module, the type of output module should be concerned. Usually, the relay output module has the characteristics of low price, wide voltage range, short life, long response time, etc.; SCR output module is suitable for frequent switching, low inductance and low power factor occasions, but the price is more expensive and the overload capacity is poor. The output module also has DC output, AC output and analog output, etc., which should be consistent with the application requirements. According to application requirements, intelligent input and output modules can be selected reasonably in order to improve the control level and reduce the application cost. Consider whether you need an expansion rack or remote I/O rack, etc.

The choice of power supply

The power supply of PLC should be designed and selected according to the requirements of the product manual when the equipment is introduced at the same time. The power supply of PLC should be designed and selected 220VAC power supply, which is consistent with the domestic grid voltage. For important applications, uninterruptible power supply or regulated power supply should be used. If the PLC itself has a usable power supply, it should be checked whether the supplied current meets the application requirements, otherwise, an external power supply should be designed. In order to prevent the external high-voltage power supply from being introduced into the PLC due to incorrect operation, it is necessary to isolate the input and output signals, and sometimes simple diodes or fuse tubes can be used for isolation.

Selecting memory

Due to the development of computer integrated chip technology, the price of memory has dropped. Therefore, in order to ensure the normal operation of application projects, the memory capacity of PLC is generally required, and selecting 8K memory at least, according to 256 I/O points. When complex control functions are required, a memory with a larger capacity and a higher grade should be chosen.