What are the Different Types of Chamfering Machines?

A chamfering machine is a specialized tool used to chamfer the end faces of pipes or plates before welding. It solves the problems of non-standard angles, rough slopes, and high work noise caused by flame cutting, grinding, and other processes. It has the advantages of easy operation, standard curve, smooth surface, and being lightweight, having a high chamfering rate, durable, and convenient to operate. It is very suitable for the welding and manufacturing fields of steel structures, boilers, pressure vessels, equipment manufacturing, shipbuilding, power, molds, chemicals, petroleum engineering, metallurgy, heads, iron towers, aerospace, and other industries.

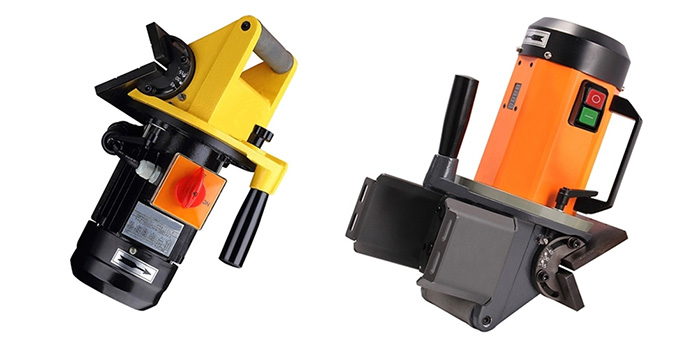

According to the popular name classification, it is divided into two types: flat chamfering machines and steel plate chamfering machines.

Flat chamfering machine

A flat chamfering machine is designed for chamfering and beveling of metal plates and is a manual push-type chamfering tool. It is suitable for chamfering and beveling metal plates before welding. Compared with similar products, it is lightweight, has low vibration, easy to operate, and safe to use.

Product features:

- The chamfering surface is smooth, flat, and free of oxidation, which is convenient for welding;

- It meets the needs of welding joints of K, V, X, and Y types;

- It is suitable for processing steel, cast iron, and hard plastics, and can also be used for processing chrome steel and other high-strength materials.

Steel plate chamfering machine

The steel plate chamfering machine has an accurate size, smooth surface, one-time forming, and no need to clean burrs. It has the advantages of convenient operation and low energy consumption, which can greatly reduce the labor intensity of workers and improve the quality of chamfers. The electric chamfering machine is lightweight (compared to similar products), with small vibration, stable operation, simple and safe operation, and is suitable for materials such as steel, cast iron, hard plastics, and non-ferrous metals.

According to the nature of machine usage, there are three types of chamfering machines: portable chamfering machines, portable automatic walking chamfering machines, and desktop chamfering machines.

Portable chamfering machine

Composition: It mainly consists of a three-phase motor, a start switch, a cast shell, a support plate, a scale ruler, a user-friendly handle, a milling cutter disc, and other components. The principle is to drive the blades on the milling cutter disc through the motor to perform chamfering operations on the workpiece.

The portable chamfering machine is lightweight, easy to use, and easy to operate. It can improve work efficiency and reduce costs. The chamfering thickness can be adjusted, and ultra-hard touch heads are installed on all four sides, which is suitable for chamfering large workpieces that have not been heat-treated, such as various molds and mechanical parts manufacturing. The portable chamfering machine does not require clamping, and the chamfering is regular, easy to adjust, economical, reliable, and greatly improves efficiency. The worktable is made of high-quality mold steel that has been heat-treated and is durable with low friction. Any length of steel, iron, copper, aluminum and other metal parts can be easily chamfered. During operation, the sliding rail is pressed against the workpiece, and the cutting is performed in the direction indicated by the arrow.

Portable automatic walking chamfering machine

Composition: The portable automatic walking chamfering machine is mainly composed of a mobile walking frame, a three-phase motor, a turbine, a rotor, a reduction device, a controller, a start switch, an emergency stop button, a reverse button, thermal magnetic protection, a cast shell, support wheels, an angled wheel, and other components. Its principle is that the motor drives the entire rolling washing cutter through the reducer, and performs milling and cutting chamfering operations through the rolling of the cutter disc. Achieve automatic walking of small plate steel and automatic walking of large plate machines.

The automatic walking flat chamfering machine has the following characteristics:

- The workpiece with the bevel angle can be used for welding without any further processing. The thickness of any cuttable material is 5-40mm, the minimum width is 70mm, and the minimum length is 150mm.

- The angle of the beveled edge is within the range of 15 degrees - 50 degrees, adjust at will, no need to replace parts.

- The pressure rod and workpiece support parts can be adjusted up and down within the range marked with the scale.

- The machine is equipped with four slits to facilitate handling and fixing long and thick workpieces.

- The flat beveling machine can operate the machine vertically or horizontally, and the workpieces that need to be cut are tightly fixed.

- Can be grooved from the left or right, flexible and convenient operation.

- All circuit equipment is installed in a dust-free box, the machine can be operated safely.

- Comply with CE certification.

The portable automatic walking chamfering machine is used for chamfering the front edge of the workpiece before welding and is used for deburring and chamfering metal plates before welding. The steel plate edge is washed and cut according to the required angle to obtain the chamfering angle required for welding.

Desktop chamfering machine

Composition: It consists of a machine body, an outer corner chamfering workstation, a positioning support table, an inner corner chamfering workstation, an inner corner rotating cutter head, an outer corner rotating cutter head, an electric motor, and a transmission mechanism. The inner and outer corner rotating cutter heads are vertically installed on the horizontal plate of the machine body, with the lower end shaft part equipped with a transmission mechanism. The inner corner rotating cutter head is exposed in the hole of the inner corner chamfering workstation located at the center of the vertically lifting table. The groove on the underside of the positioning support table above the outer corner rotating cutter head is combined with the hole of the outer corner cutter head exposed on the end face to form the hole for the outer corner rotating cutter head. The lifting device is set between the outer corner chamfering workstation and the horizontal plate of the machine body, which enables the outer corner chamfering workstation to lift up and down so that the hole for the outer corner rotating cutter head can be adjusted.

The desktop composite high-speed chamfering machine can easily achieve 3D chamfering for products with straight or curved lines (such as external circles, internal holes, and waist-shaped holes) and irregular inner and outer cavity edges. It can replace CNC machining centers and can chamfer parts that cannot be processed by ordinary machine tools. Straight chamfering, arc chamfering, and irregular curve chamfering can all be completed on one machine, which has the function of one machine for multiple uses.

Fully automatic chamfering machine

Fully automatic chamfering machines have been widely used in the market, and are available in two styles: double workstation and single workstation. They can automatically lift and change tools and can complete rough grinding, fine grinding, and polishing in one step, with precise processing standards. This product also adopts a touchscreen design, which is easy and fast to operate and can be operated by ordinary workers.