What is a Infrared Thermometer?

An infrared thermometer (infrared temperature gun) consists of an optical information system, a photoelectric detector, signal amplification and processing, and data display and output. The optical design system converges on the targets within its field of view and the infrared radiation they emit. Infrared energy primarily focuses on the photoelectric detector and is converted into a corresponding electrical signal, which is then converted into the temperature of the measured target after appropriate calibration.

Infrared thermometers employ a non-contact temperature measurement method to accurately measure the surface temperature of objects. They are characterized by high precision, rapid response, and a high safety factor. Infrared thermometers are suitable for various applications in manufacturing, quality control, online equipment fault detection, safety protection, and resource conservation, as well as in daily life, such as preventive maintenance of electrical equipment, quality management in production lines, and food safety and security in restaurants.

Features

Infrared temperature measurement technology plays a crucial role in various aspects of the production process, including quality control and inspection, online equipment fault detection, safety protection, and resource conservation. Over the past two decades, non-contact infrared body thermometers have rapidly developed technologically, with their features continuously improving and their applications expanding. Compared to touch-based temperature measurement methods, infrared thermometers offer advantages such as fast response time, non-contact measurement, safe usage, and durability. Non-contact infrared thermometers come in three major product series: handheld, online, and scanning, each with various options and computer technology integration. Within these series, there are numerous models and specifications, making the correct selection of an infrared thermometer model and specification crucial for users. The ATO store offers a wide range of infrared thermometers including Handheld Non Touch Infrared Forehead Body Thermometer, Handheld Thermal Imaging Camera.

Infrared Thermometer Types

Infrared temperature measuring instruments primarily fall into three categories: infrared thermal imagers, infrared thermographic cameras, and infrared thermometers (spot thermometers). Infrared thermometers are composed of optical components, a photoelectric detector, a signal amplifier, signal analysis, and display output. Optical components collect the infrared radiation energy from the target within the field of view, and the field of view angle is determined by the optical parts and device specifications. Infrared energy is focused on the photoelectric detector and converted into a corresponding electronic signal. This data signal is then processed through amplifiers and signal analysis circuits, corrected based on the target's emissivity with the help of internal optimization algorithms of the device, and finally transformed into the temperature of the measured object. The function of an infrared thermometer is to convert the radiation emitted by an object in the form of infrared light into an electronic signal. The magnitude of infrared radiation is matched with the temperature of the substance, and based on the size of the converted electronic signal, the temperature of the object can be determined.

Function

Infrared thermometers are highly versatile in their applications. They can effectively inspect target objects regardless of environmental conditions, whether it is during the day or at night. Infrared thermometers overcome the limitations of traditional inspection techniques and human eyes, providing a reliable means to continue normal inspection work.

How Does an Infrared Thermometer Work?

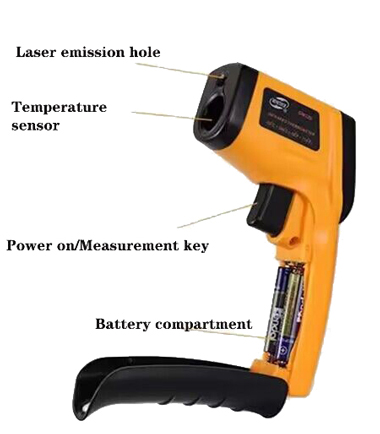

Infrared thermometers operate based on the concept that all objects emit thermal radiation in the form of infrared light. The amount of radiation emitted is directly proportional to the object's temperature. An IR thermometer consists of the following key components:

- Optical System: This component focuses the infrared radiation from the target object onto the next part of the device.

- Infrared Sensor: The sensor captures the focused infrared radiation and converts it into an electrical signal.

- Signal Processing: The electrical signal is then processed using built-in algorithms to provide an accurate temperature reading.

- Display: The temperature reading is displayed on the thermometer's screen, making it easy for the user to interpret.

Applications of Infrared Thermometers

Infrared thermometers find applications in a wide range of fields due to their non-contact and rapid temperature measurement capabilities. Some common applications include:

- Medical and Healthcare: Infrared thermometers are frequently used to measure body temperature, particularly in situations where contact thermometers may not be suitable or hygienic.

- Industrial and Manufacturing: IR thermometers are employed for checking the temperature of machinery, equipment, and materials, enabling preventive maintenance and quality control.

- Food Service and Safety: In the food industry, these thermometers are used to ensure food safety and compliance with temperature regulations during food preparation and storage.

- HVAC and Energy Efficiency: Infrared thermometers help identify energy inefficiencies and temperature variations in buildings, aiding in HVAC system maintenance and energy conservation.

- Automotive: They are used for diagnosing engine and vehicle issues by measuring the temperature of various components.

Benefits of Infrared Thermometers

Infrared thermometers offer several advantages, including:

- Non-contact Measurement: They provide temperature readings without physically touching the object, reducing contamination risks.

- Speed and Convenience: IR thermometers provide quick and instantaneous results, making them ideal for fast-paced environments.

- Safety: In applications where contact may not be safe or feasible, such as electrical troubleshooting or medical settings, infrared thermometers offer a safer alternative.

- Versatility: These thermometers can measure a wide range of temperatures and are suitable for various materials, from solids to liquids and gases.

Infrared thermometers have become indispensable test tools in a variety of industries and settings, thanks to their accuracy, speed, and non-contact nature. Whether you're concerned about your health, need to maintain machinery, or ensure food safety, an infrared thermometer provides a reliable solution for temperature measurement. Understanding how these devices work and their applications can help you appreciate the role they play in our daily lives.