What is a Pneumatic Screw Driver?

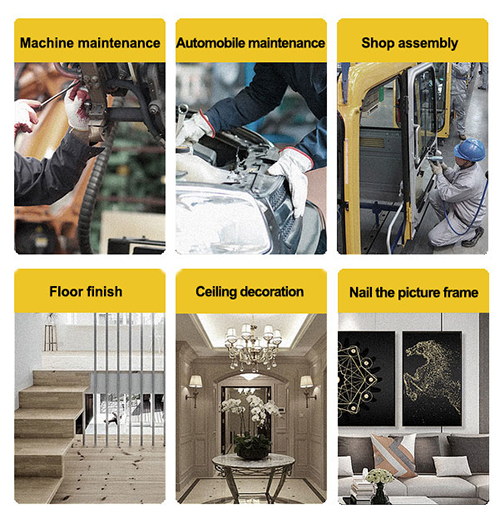

Pneumatic screwdrivers are mainly used for various assembly operations and are composed of air motors, hammering devices, or reduction devices. Because of its speed, high efficiency, and low-temperature rise, the pneumatic screwdriver has become an indispensable tool in the assembly industry. Today, we will introduce its classification, working principle, feature, and maintenance.

Pneumatic screwdriver classification

Pneumatic screwdrivers can be divided into automatic pneumatic screwdrivers and semi-automatic screwdrivers according to the degree of intelligence. A screwdriver equipped with an adjusting and limiting torque device is called a fully automatic adjustable torque screwdriver.

And there is no adjustment device, just use the switch knob to adjust the size of the air intake to control the size of the rotating speed or torque screwdriver, which is called a semi-automatic non-adjustable torque screwdriver.

In addition, there are hand screwdrivers and push-down electric screwdrivers, and so on. These smart air drivers can be used for a variety of assembly tasks.

Features

- Since the speed of the pneumatic screwdriver is generally relatively fast, the motor in it is driven by high-pressure gas, and the high-pressure air will take away a large amount of heat generated by friction in the parts during operation, so the pneumatic screwdriver will not lose heat even if it works at a high frequency for a long time.

- The pneumatic screwdriver uses a mechanical brake, and the change of air pressure has a great influence on the torque, so the error will be large, and the repeatability is about 5% to 3%.

- The pneumatic screwdriver uses compressed gas as the power source. As long as the air pipeline is properly arranged, the air consumption of each pneumatic screwdriver is about 0.28 square meters per second, which is relatively more energy-saving and environmentally friendly.

- Pneumatic screwdrivers do not need to consume electricity or oil. They only need to add some lubricating oil regularly for maintenance, so it is more economical.

Working principle

A pneumatic screwdriver is a device that uses compressed air as a power source, converting the compressed air into mechanical energy to drive the screwdriver head to rotate, so as to achieve the purpose of tightening or loosening the screw.

Compressed air is generated by an air compressor and delivered to the pneumatic screwdriver through an air tube. An air motor is installed inside the air screwdriver, and the air motor converts the kinetic energy of the air into mechanical energy to drive the shaft of the bearing to rotate the screwdriver head.

The pneumatic screwdriver head embeds the screw that needs to be tightened or loosened, covers the screw head, rotates the screwdriver head, and drives the screw to rotate, thereby realizing the operation of tightening or loosening the screw. Due to the advantages of high speed and large torque, pneumatic screwdrivers are widely used in screw disassembly and maintenance in many industrial and mechanical fields.

How to use a pneumatic screwdriver?

- Gently switch the gas valve indicator switch (R for forward rotation-L for reverse rotation) to rotate the direction.

- The motor can be started to rotate by pressing down, which can save the movement of pushing the lever and increase the force efficiency.

- It is easy to adjust the torque size. Turn the torque adjustment ring to the right to tighten, and the torque will increase and become larger; turn the adjustment ring to the left to tighten, and the torque will decrease and become smaller.

- When the load reaches the preset torque value, the air motor will stop automatically.

Pneumatic screwdriver maintenance matters

- If the pneumatic screwdriver is not used for a long time, it is best to lubricate the knife head for storage, otherwise, it will be rusted and damaged. Therefore, it is very important to develop the habit of lubricating and saving on a daily basis.

- Before lubricating with a manual refueling pot, you need to separate the pneumatic screwdriver from the air pressure tube, and then add lubricating oil into the intake nut. After connecting the pneumatic screwdriver and the air tube, press down the pneumatic screwdriver to idle for about two seconds to complete the lubrication and storage. Maintaining this way 1-2 times a day can prolong the life of the tool.

- When replacing the soft sheath, first put the sheath into the torque adjustment ring, and then inflate it with air pressure to increase the outer diameter of the sheath, and at the same time squeeze it into the sheath.

- The pneumatic screwdriver is a relatively delicate tool, so it must be handled with care when using it, it must not be bumped or dropped to the ground, and it must be checked regularly.

- After use, it should be wiped clean with cotton yarn and placed in the bracket. Before using the pneumatic screwdriver, please read the instruction manual of the screwdriver carefully, and use it according to its operating specifications.

- The torque of the pneumatic screwdriver is more suitable in the range of 45-75.

- Do not directly adjust from the lowest gear to the highest gear (and vice versa) during use. Such an operation will easily cause the clutch steel ball and torque thimble to fall off.

- Tighten the fixing ring (or torque sheath) of the pneumatic screwdriver before use, because the air source is connected to the air inlets at both ends, and the interface should match the pneumatic screwdriver.

- The internal parts of the pneumatic screwdriver should not come into contact with grease or other corrosive liquids.

- For the effectiveness of maintenance, please protect the serial number and warranty card of the pneumatic screwdriver.