What is a Spring Balancer?

Spring balancer is a common mechanical device whose main function is to balance the weight of an object, enabling it to maintain a balanced state without the need for external force support. In industrial production, spring balancers are widely used in various mechanical equipment, such as cranes and machine tools, etc. In this article, ATO industrial automation will introduce the basic information about the spring balancer (including components, working principle, advantages and its applications) for you.

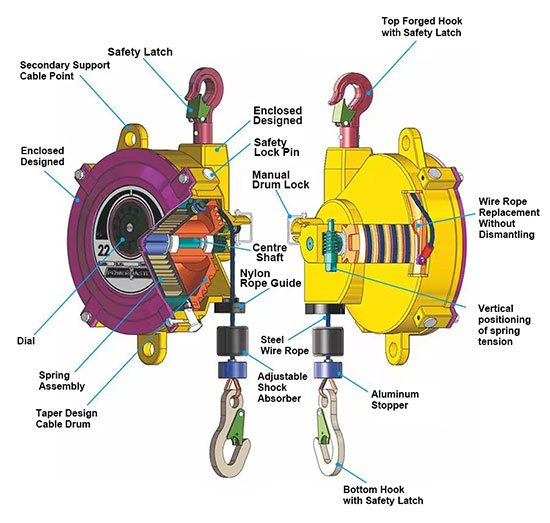

Components of Spring Balancer

- Spring: It is the core component of a spring balancer, usually using torsion or tension springs, which are fixed on a bracket or hook. The elastic force of a spring can balance the gravity of an object and keep it in a balanced state.

- Bracket: used to fix springs and pulleys, usually made of metal material. Brackets are usually installed on the ceiling to suspend objects in the air.

- Pulley: Installed above the bracket and generally made of steel material. Pulleys can reduce the force of gravity on objects and convert unstable gravity into stable tension.

- Hooks: used for attaching objects.

- Adjusting nuts: used to adjust the tension of the spring.

Working Principle of Spring Balancer

The working principle of a spring balancer is straightforward, primarily consisting of a spring, a support structure, a pulley, and an object. When an object is hung on the spring balancer, the spring undergoes deformation due to the gravitational force acting on the object. At this point, the spring generates an upward reaction force, equal in magnitude but opposite in direction to the weight of the object. This reaction force keeps the object in equilibrium, preventing it from falling or rising. The working principle of a spring balancer can be explained through the following steps:

- Install the Spring: Initially, install the spring on the support structure. The support structure typically comprises a fixed base and a movable arm used for hanging the load and adjusting the tension in the spring.

- Hang the Load: Suspend the load that needs to be balanced on the spring. The load can be connected to the spring using hooks, fixtures, or other suitable attachment methods.

- Adjust Tension: Use an adjustment device (such as a handle or a screw mechanism) to alter the spring tension. This device is usually located on the support structure and can be rotated or moved to change the tension. Increasing tension causes the spring to contract, while decreasing tension causes the spring to elongate.

- Achieve Balance: Gradually adjust the tension until the restoring force equals the gravitational force in magnitude but acts in the opposite direction. When equilibrium is reached, the load will stay in a stable position, maintaining relative stillness.

- Adjust Position: If there is a need to change the position of the load, adjustments in tension can be made. Increasing tension causes the load to rise, while decreasing tension causes the load to descend. Therefore, by fine-tuning the tension, precise control over the position of the load can be achieved.

Advantages of Spring Balancer

- Simple and User-Friendly:

The structure of spring balancers is simple, making them easy to use. - High Reliability:

Spring balancers exhibit high stability and reliability during operation. - Wide Applicability:

Spring balancers are suitable for various situations and needs. - Space Efficiency:

Spring balancers take up minimal space, making them suitable for environments with limited room. - Adjustable Tension:

Tension in the spring can be easily adjusted to accommodate different loads and applications, providing flexibility in usage.

Applications of Spring Balancer

- Industrial Production:

In industrial production, spring balancers are commonly used to support and balance heavy equipment or tools. For instance, in the automotive manufacturing process, various fixtures and brackets are employed to secure automotive components. These fixtures and brackets often require the use of spring balancers to maintain their relative stable positions. - Medical Field:

In the medical field, spring balancers find widespread application in settings such as operating rooms and diagnostic rooms. For example, in the operating room, doctors need to use various types of instruments for surgical procedures, and these instruments often require spring balancers to maintain their relative stable positions. - Home Life:

In home life, spring balancers also find certain applications. For instance, in the kitchen, spring balancers can be used to support and balance heavy items such as pots and pans. This helps reduce the burden on arms and shoulders, making cooking more relaxed and comfortable. - Aerospace:

In the aerospace industry, spring balancers are used to balance and control various aerospace equipment in areas such as aircraft manufacturing, flight simulators, and space stations. They provide reliable support and stability under extreme conditions. - Lighting Equipment:

In places like stage lighting, film studios, and industrial workshops, spring balancers can be used to suspend and balance various types of lighting equipment, such as fixtures, cameras, and amplifiers.

Spring balancer is a very practical mechanical device with a simple and effective working principle, which can provide stable support and balance for various mechanical equipment. Spring balancers will be more widely used and developed in future industrial production.