What is a Swing Check Valve?

Swing check valves play a crucial role in various fluid control systems, ensuring the smooth and efficient flow of liquids while preventing backflow. In this blog post, we will delve into the intricacies of swing check valves, exploring their design, functionality, and diverse applications.

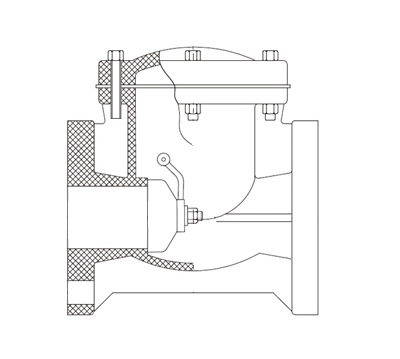

What is a Swing Check Valve?

A swing check valve is a type of check valve designed to permit the flow of fluid in one direction while preventing reverse flow. Its distinctive feature is the swinging disc, which swings open during forward flow and closes under the influence of gravity to prevent backflow.

Components and Design

Body:

The body of a swing check valve is a critical component that houses the other parts and provides structural integrity. It is typically made from robust materials like stainless steel, cast iron, or bronze to withstand the pressures and conditions of different applications.

The design of the body varies based on the valve's purpose and the type of fluid it will handle. The body shape and connections may differ in industrial, residential, or commercial settings.

Disc:

The swinging disc is a pivotal element in the valve's operation. It is connected to the hinge mechanism and swings freely within the valve body. The disc's material is carefully chosen to resist corrosion and wear, ensuring longevity and reliability.

The disc's size and weight are crucial factors. A properly sized disc allows for efficient flow while the weight influences the closing speed. Heavy-duty applications may incorporate a larger, heavier disc to manage higher fluid velocities and pressures.

Hinge Mechanism:

The hinge mechanism is the pivot point on which the disc swings. It can be a simple hinge pin or a more complex design, depending on the valve's specifications. The hinge should allow for smooth movement to ensure the disc opens and closes effectively without sticking or jamming.

Corrosion-resistant materials and proper lubrication are essential for the hinge mechanism to maintain smooth operation over an extended period.

Spring Option:

Some swing check valves are equipped with springs to assist in the closure of the disc. These springs help overcome the effects of gravity, ensuring a faster and more controlled closing of the valve.

Springs are particularly beneficial in preventing water hammer, a phenomenon where the sudden stop of fluid flow creates a shockwave, potentially damaging the valve and the piping system. The spring's role is to dampen this shock, prolonging the valve's life and preserving the system's integrity.

How Swing Check Valves Work

Forward Flow:

During forward flow, the fluid exerts pressure on the swinging disc, causing it to pivot open against the hinge. This allows the fluid to pass through the valve with minimal resistance.

The design of the valve ensures that the disc does not obstruct the flow, promoting efficient fluid movement through the system.

Backflow Prevention:

When the fluid flow stops or reverses, gravity comes into play. The swinging disc, being hinged, naturally swings back to a closed position under its own weight.

The disc's closure prevents the backflow of fluids, maintaining the desired one-way flow in the system. The design of the disc and hinge mechanism is crucial in creating a reliable and effective barrier against backflow. The addition of springs, if present, further aids in the prompt closure of the valve to prevent any reverse flow.

Advantages of Swing Check Valves

Low Maintenance:

- Simple Design: Swing check valves have a straightforward design with minimal moving parts. This simplicity contributes to their reliability and reduces the need for frequent maintenance. Fewer components mean fewer potential points of failure, making these valves easy to operate and maintain.

- Ease of Inspection: The design allows for easy visual inspection of the swinging disc and hinge mechanism, facilitating quick identification of any potential issues. This ease of inspection simplifies maintenance procedures, leading to shorter downtimes and lower maintenance costs.

Efficient Flow Control:

- Unobstructed Flow: During forward flow, the swinging disc pivots open to allow the fluid to pass through the valve unobstructed. This design minimizes resistance to flow, ensuring efficient and smooth operation of fluid systems.

- Low Pressure Drop: The streamlined design of swing check valves results in a low-pressure drop across the valve. This characteristic is especially advantageous in applications where maintaining optimal fluid pressure is critical.

Versatility:

- Materials and Sizes: Swing check valves are available in a wide range of materials, including stainless steel, cast iron, and bronze, allowing users to choose a material that best suits the specific application and fluid type. Additionally, they come in various sizes to accommodate different pipe diameters, making them versatile and adaptable to diverse systems.

- Configurations: The versatility extends to different configurations, such as wafer, lug, or flanged, providing flexibility in installation and integration into various piping systems.

Reliable Backflow Prevention:

- Gravity-Assisted Closure: The design of swing check valves leverages gravity for the closure of the disc when flow stops or reverses. This natural closing mechanism ensures reliable backflow prevention without the need for external power sources or complex control systems.

- Prevention of Water Hammer: In systems with sudden stops or reversals of flow, swing check valves with optional springs assist in the quick closure of the disc, preventing water hammer. This feature protects the valve and the entire piping system from potential damage caused by hydraulic shocks.

Long Service Life:

- Durable Materials: Swing check valves are often constructed from durable and corrosion-resistant materials. This ensures a long service life, even in demanding environments or when handling corrosive fluids.

- Wear-Resistant Disc: The swinging disc is designed to withstand continuous cycles of movement without significant wear. Proper material selection and robust construction contribute to the longevity of the valve.

Swing check valves are indispensable components in fluid control systems, providing efficient flow regulation and preventing backflow. Understanding their design, functionality, and applications is crucial for ensuring the optimal performance of various industrial processes. Whether in water distribution systems, chemical plants, or HVAC systems, the versatility and reliability of swing check valves make them a fundamental element in fluid control technology.