What is a Plug Valve?

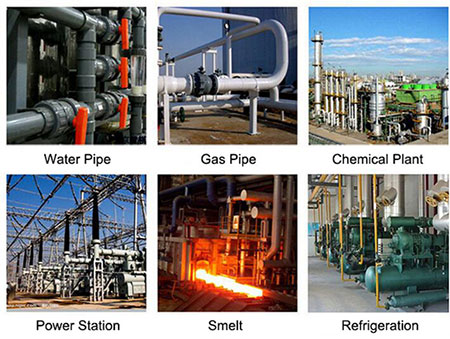

The design of a plug valve is inspired by the movement of the plug, which rotates to control the flow of fluid. This design enables plug valves to provide precise flow regulation in a wide range of operating conditions to meet the needs of different industrial processes. Whether in chemical plants, power stations, or water treatment systems, plug valves have demonstrated excellent performance. ATO.com will introduce you to the basics of plug valves, which will help you understand and better utilize this tool.

Plug valves are simple valves that open and close quickly and with low resistance, and they are generally operated by a handle. When the handle of the plug valve and the valve body are parallel to the full open position, when the handle of the plug valve and the valve body are perpendicular to the full closed position, the plug valve generally can not be used as a control valve.

Due to the movement between the rotary sealing surface with wiping effect, and in the fully open can completely prevent contact with the flowing medium, so it usually can also be used for suspended particles of the medium. Another important characteristic is that it is easy to adapt to a multi-channel structure so that a valve can get two, three, or even four different flow channels. This simplifies the design of the piping system and reduces the number of valves and connections required in the equipment.

Principle of Operation

A valve with a through-hole plug as the opening and closing parts. Plug the body with the valve stem rotation, to realize the opening and closing action. Small plug valves without packing are also known as "Cocker". The plug valve plug body is mostly conical (also cylindrical), and the valve body of the conical hole surfaces with the composition of the sealing vice. The plug valve is the earliest use of a valve with, a simple structure, rapid switching, and low fluid resistance. Ordinary plug valves rely on the finishing of the metal plug body and the valve body to seal the direct contact between the body, so the sealing is poor, the opening and closing force is large, easy to wear and tear, and usually can only be used for low-pressure (not higher than 1 MPa) and small-diameter (less than 100 millimeters) occasions.

Classification

The structural form can be divided into tightly set plug valve, self-sealing plug valve and oil-filled plug valve four. According to the channel form, it can be divided into a straight-through plug valve, a three-way plug valve, and a four-way plug valve three. There are also ferrule-type plug valves. Plug valves are categorized according to use including soft seal plug valve, oil lubricated hard seal plug valve, lifting plug valve, three-way and four-way plug valve.

- Soft Seal: Soft Seal Plug Valve is commonly used in corrosive, highly toxic, and highly hazardous media and other harsh environments, strictly prohibits the leakage of the occasions, as well as the valve material will not form a contaminated medium of the occasion. The valve body can be selected according to the working medium of carbon steel, alloy steel, and stainless steel materials.

- Oil Lubrication Hard Seal: Oil lubrication hard seal plug valve can be divided into conventional oil lubrication plug valve and pressure balanced plug valve. Special grease is injected from the top of the plug body into the valve body between the cone hole and the plug body, forming an oil film to reduce the valve opening and closing torque and improve the sealing and service life. Its working pressure is up to 64MPa, the highest working temperature is up to 325 degrees, and the maximum caliber is up to 600mm.

- Lifting: The lifting plug valve has a variety of structural forms, the lifting plug valve according to the material of the sealing surface is divided into two kinds soft seal and hard seal. The basic principle is to open the plug rise, the plug and then turn 90 degrees to the valve fully open process can reduce the friction with the valve body sealing surface. Close the valve so that the plug rotates 90 degrees to the closing position and then down with the valve body sealing surface contact to achieve sealing.

- Three-way and Four-way: The plug valve channel has a variety of forms. The common straight-through type is mainly used to cut off the fluid. The three-way plug valve and four-way plug valve for fluid reversing plug valve opening and closing member is a cylinder with a hole, rotating around the axis perpendicular to the channel, to achieve the purpose of opening and closing the channel. Three-way and four-way plug valves are suitable for Shanghai engineering devices, changing the direction of media flow or media distribution occasions. According to the requirements of the use of working conditions, can choose a soft seal liner or soft seal, hard seal lifting plug valve.

Advantages of Plug Valves

- Plug valve for frequent operation, open and close quickly and easily.

- Plug valve fluid resistance is small.

- The plug valve structure is simple, relatively small in size, lightweight, and easy to maintain.

- Good sealing performance.

- Not restricted by the installation direction, the flow direction of the medium can be arbitrary.

- No vibration, low noise.

Disadvantages of Plug Valves

- The plug valve body and seat contact surface are large, so it is easy to produce wear and tear leakage caused by poor sealing, maintenance is difficult. The spool of the plug valve may be deformed at high temperatures, and it is easy to get stuck in high temperatures and high pressure.

- Because plug valves are easily deformed under high temperatures, plug valves are mostly used for lower temperature media, commonly used in the following pipelines.

- Plug valves can be used for pipelines that need to be opened and closed quickly.

- Plug valves can be used for low-pressure container liquid level indicators.

- Plug valves can be used in places where they do not need to be operated frequently or for inspection purposes.

Application Areas

- Oil and Gas Industry: Plug valves are widely used in the oil and gas industry to control the flow of fluids in oil and gas wells and pipelines. Their reliable sealing and corrosion resistance make them ideal for these extreme conditions.

- Chemical Industry: Plug valves are used in the chemical industry to regulate the flow of a variety of chemicals to ensure precise control and safe operation of the production process due to the spool design of the valve to effectively control the flow of fluids.

- Energy Industry: In the energy industry, plug valves are widely used in fields such as thermal power plants and nuclear power plants to control the flow of cooling water, steam, and other media to ensure the normal operation of equipment.

- Water Treatment and Water Supply System: Plug valves play a key role in the field of water treatment, used to regulate and control the flow of water in the water supply system, to ensure the stable operation of the water supply system.

- Food and Pharmaceutical Industry: As the selection of materials for plug valves can meet hygiene standards, they are widely used in the food and pharmaceutical industry for controlling the flow of food, medicine, and other fluids.

- Paper Industry: Plug valves are used in the paper industry to control the flow of various liquids and chemicals, ensuring precise control and efficient operation in the production process.

- Shipbuilding Industry: In the field of ships, plug valves are used to control the flow of fluids in various systems of ships, such as cooling water, oil, and so on.

As a key component in fluid control systems, plug valves provide efficient and reliable fluid control solutions for industrial production and various processes. Its precise flow regulation, high temperature, and high-pressure resistance make it widely used in many industries. In the future, as technology continues to advance, the design and manufacturing technology of plug valves will continue to evolve, bringing more innovations to the field of fluid control and meeting increasingly complex industrial needs. Whether it is to improve production efficiency or to protect industrial safety, plug valves will continue to play an irreplaceable role, contributing to the stable operation of industrial systems.