What is a Plunger Valve?

A plunger valve is a commonly used type of valve with features like a simple structure, reliable sealing, and flexible operation. It operates by controlling the flow of media through the up-and-down movement of a plunger. In industrial production, plunger valves are widely used in various process pipeline systems and play a significant role in control. In this article, ATO industrial automation will briefly introduce plunger valve to you, including its structure, working principle, characteristics, etc., to help you have a better understanding of it.

Structure and Performance of Plunger Valve

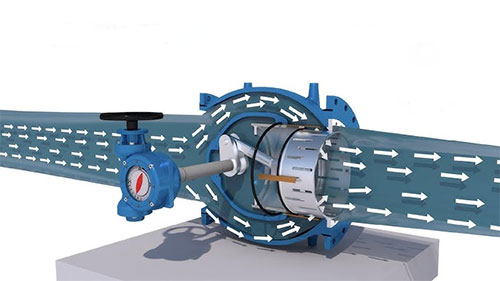

A plunger valve is comprised of components such as the valve body, valve cover, valve stem, plunger, cage, sealing rings, handwheel, and others. When the handwheel is rotated, it drives the plunger to move up and down within the cage, thus completing the opening and closing functions of the valve.

Between the plunger and the sealing rings in the valve, a slight interference fit is employed. By adjusting the pressure cover's flange bolts, the sealing rings are compressed. This ensures that the lateral force generated by the sealing rings against the hole surface in the valve body and the outer circumference of the plunger provides the seal, thereby guaranteeing the valve's sealing integrity. This design eliminates internal leakage, while also allowing for quick valve opening and closing.

Since the sealing rings are made of a non-toxic, new-type sealing material with strong resilience and high wear resistance, they maintain their elasticity even when exposed to prolonged high temperatures and pressures. Consequently, the sealing performance is reliable and long-lasting.

Working Principle of Plunger Valve

The opening and closing of a plunger valve are achieved by the linear up-and-down motion of the plunger, which is driven by the valve stem. Its performance is similar to that of a globe valve and can also serve as a throttling valve. When the handwheel is rotated, the valve stem moves the plunger up and down between two sealing rings to control the valve's opening and closing.

Control Methods for Plunger Valve

Plunger valves can be operated manually or automatically. Manual control involves human operation to raise or lower the plunger for media control. Automatic control methods typically use electric or pneumatic devices to control the plunger's movement for automatic media control.

Characteristics of Plunger Valve

- Plunger valves operate based on radial sealing principles and have the following characteristics:

- Simple structure, flexible operation, and excellent sealing

- Easy to disassemble and maintain

- Long service life

- Suitable for handling media with suspended particles

- Allows sensitive flow control

Note

- The opening and closing direction for plunger valve operation should be clockwise to close.

- Plunger valves in pipeline networks should be manually operated with a limited number of rotations, especially for large-diameter plunger valves (between 200-600 rotations).

- To facilitate single-person operation, the torque required for opening and closing the valve under pipeline working conditions should be 240 N·m.

- Plunger valve operation end should have a square or D-shaped socket, with standardized dimensions, and it should face the ground. Electromagnetic valves are not suitable for use in underground pipeline networks.

- The indicator for plunger valve opening and closing should have scale lines cast on the gearbox cover or the housing of the display dial after direction change. All of them should face the ground, and the scale lines should be painted with fluorescent powder for visibility. The pointer material can be stainless steel in well-maintained conditions, otherwise painted steel should be used, not aluminum foil. The pointer should be conspicuous and securely fixed, using rivets once the accurate opening and closing of the electrically operated control valve has been achieved.

- If a plunger valve is buried deep underground, and the distance between the operation mechanism and the ground is greater than 21.5 meters, an extension rod facility should be provided, securely fixed for ease of observation and operation from the ground. This means that for the operation of diaphragm pumps in the pipeline network, downhole work should be avoided.

Overall, plunger valves are a flexible valve type suitable for industrial applications that require accurate fluid control. Their design and working principles can be adjusted and optimized according to specific application requirements to ensure stable process control and security.