Difference between Plug Valve and Ball Valve

Plug Valve

The plug valve is a rotary valve in the shape of a closing member or a plunger. By rotating 90°, the channel port on the valve plug is the same as or separated from the channel port on the valve body, so as to realize the opening or closing of a valve. The shape of the plug of the plug valve can be cylindrical or conical. In cylindrical plugs, the passages are generally rectangular. In conical plugs, the passages are trapezoidal. These shapes make the structure of the plug valve light, but at the same time, it also produces a certain loss. Plug valves are best suited for shut-off and on-media and diverting applications, but may also be used for throttling depending on the nature of the application and the erosion resistance of the sealing surface. Since the movement between the sealing surfaces of the plug valve has a wiping effect, it can completely prevent contact with the flowing medium when it is fully opened, so it can usually also be used for medium with suspended particles. Another important feature of the plug valve is that it is easy to adapt to the multi-channel structure, so that one valve can obtain two, three, or even four different flow channels. This simplifies the design of the piping system, reduces the amount of valves, and some connection fittings required in the equipment.

The plug valve is a rotary valve in the shape of a closing member or a plunger. By rotating 90°, the channel port on the valve plug is the same as or separated from the channel port on the valve body, so as to realize the opening or closing of a valve. The shape of the plug of the plug valve can be cylindrical or conical. In cylindrical plugs, the passages are generally rectangular. In conical plugs, the passages are trapezoidal. These shapes make the structure of the plug valve light, but at the same time, it also produces a certain loss. Plug valves are best suited for shut-off and on-media and diverting applications, but may also be used for throttling depending on the nature of the application and the erosion resistance of the sealing surface. Since the movement between the sealing surfaces of the plug valve has a wiping effect, it can completely prevent contact with the flowing medium when it is fully opened, so it can usually also be used for medium with suspended particles. Another important feature of the plug valve is that it is easy to adapt to the multi-channel structure, so that one valve can obtain two, three, or even four different flow channels. This simplifies the design of the piping system, reduces the amount of valves, and some connection fittings required in the equipment.

Plug Valve Applications

Plug valves are widely used in oilfield mining, transportation and refining equipment, and are also widely used in petrochemical, chemical, gas, natural gas, liquefied petroleum gas, HVAC and general industries.

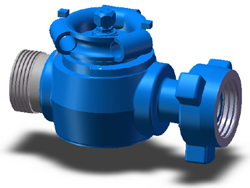

Ball Valve

The ball valve is mainly used to cut off or connect the medium in the pipeline, and can also be used for the regulation and control of the fluid. The hard-sealed V-shaped ball valve has a strong connection between the V-shaped ball core and the metal valve seat of hard alloy surfacing. Shear force, especially suitable for media containing fibers and tiny solid particles. The multi-port ball valve on the pipeline can not only flexibly control the confluence, diversion, and switching of the flow direction of the medium, but also can close any channel and connect the other two channels. This type of valve should generally be installed horizontally in the pipeline.

The ball valve is mainly used to cut off or connect the medium in the pipeline, and can also be used for the regulation and control of the fluid. The hard-sealed V-shaped ball valve has a strong connection between the V-shaped ball core and the metal valve seat of hard alloy surfacing. Shear force, especially suitable for media containing fibers and tiny solid particles. The multi-port ball valve on the pipeline can not only flexibly control the confluence, diversion, and switching of the flow direction of the medium, but also can close any channel and connect the other two channels. This type of valve should generally be installed horizontally in the pipeline.

Ball Valve Advantages

- The fluid resistance is small, and the full-bore ball valve basically has no flow resistance.

- Simple structure, small size and light weight.

- Tight and reliable. It has two sealing surfaces, and various plastics are widely used for the sealing surface materials of the ball valve at present, which has good sealing performance and can achieve complete sealing. It has also been widely used in vacuum systems.

- Easy to operate, quickly to open and close, only need to rotate 90° from fully open to fully closed, which is convenient for long-distance control.

- The maintenance is convenient, the ball valve has a simple structure, the sealing ring is generally movable, and it is more convenient to disassemble and replace.

- When fully open or fully closed, the sealing surfaces of the ball and the valve seat are isolated from the medium, and the sealing surface of the valve will not be eroded when the medium passes through.

- It has a wide range of applications, with diameters ranging from small to several millimeters to several meters, and can be applied from high vacuum to high pressure.

- Since the ball valve has wiping properties during the opening and closing process, it can be used in media with suspended solid particles.