What is a Toe Jack?

In the world of heavy lifting and positioning, precision and efficiency are paramount. Toe jacks, a versatile and powerful lifting tool, have emerged as indispensable equipment in various industries. This article will explore the working principle, advantages, and applications of toe jacks, shedding light on how they have become a go-to solution for lifting tasks that demand accuracy and reliability. In this article, ATO industrial automation will briefly introduce toe jack to you, including its structure, working principle, characteristics, etc., to help you have a better understanding of it.

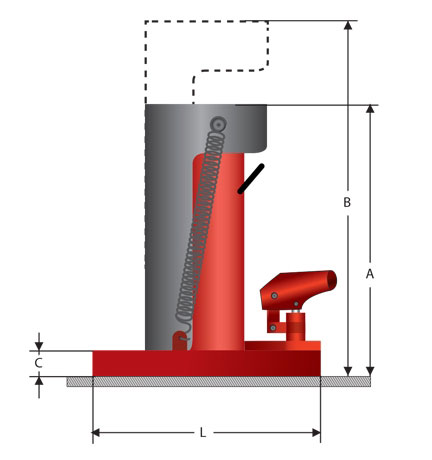

Structure of Claw-Type Jack

The claw-type jack is composed of a base, claw rod, bearing seat, and hydraulic cylinder.

- The base serves as the support for the claw-type jack and is welded from steel plates to form a solid unit.

- The bearing seat is the mounting position for the bearings of the claw-type jack, and it is constructed by welding two semicircular steel plates together to create a unified structure.

- The hydraulic cylinder is the component used for power transmission, consisting of a piston rod and a sealing cover assembled together to form a cohesive part.

Working Principle of Toe Jack

Toe jacks operate on a simple yet ingenious mechanical principle. The device consists of a hydraulic cylinder fitted with a toe, which is a small, adjustable extension that makes contact with the load. When hydraulic pressure is applied to the cylinder, the toe extends, lifting the load with precision. The design allows for controlled and incremental lifting, making toe jacks ideal for situations where precise adjustments are crucial.

Advantages of Toe Jack

- Precision Lifting: One of the primary advantages of toe jacks is their ability to lift loads with exceptional precision. The controlled hydraulic action and adjustable toe enable operators to make fine adjustments, ensuring accurate positioning.

- Compact Design: Toe jacks are known for their compact and portable design. This makes them highly maneuverable in tight spaces, allowing for efficient lifting even in confined environments.

- High Lifting Capacity: Despite their compact size, toe jacks boast impressive lifting capacities. This makes them suitable for a wide range of applications, from machinery installation to structural alignment.

- Safety Features: Modern toe jacks come equipped with safety features such as overload protection and built-in bypass valves. These features enhance the safety of lifting operations, preventing damage to both the equipment and the load.

Applications of Toe Jack

Toe jacks find applications across diverse industries:

- Machinery Installation and Removal: Toe jacks are invaluable for precisely positioning heavy machinery during installation or relocation, ensuring a level and secure setup.

- Structural Alignment: In construction and engineering projects, toe jacks are used to align and position structural components with accuracy, facilitating seamless assembly.

- Maintenance Tasks: Whether it's lifting heavy equipment for maintenance or adjusting the position of industrial components, toe jacks provide a reliable solution for various maintenance applications.

- Material Handling: Toe jacks are utilized in material handling tasks, aiding in the lifting and positioning of heavy loads with efficiency and control.

Toe jacks stand out as reliable and efficient lifting solutions, offering precision and control in a compact and portable design. Their versatility makes them indispensable in industries where accuracy and safety are paramount. As technology continues to advance, toe jacks evolve to meet the increasing demands of modern lifting applications, reaffirming their status as essential tools for professionals across various sectors.