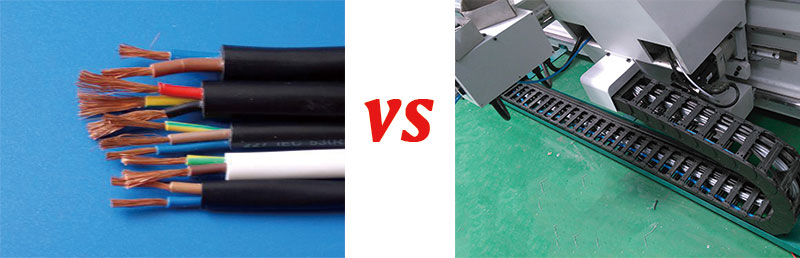

Difference Between Drag Chain and Ordinary Cable

In the industrial field, cable drag chain has been more and more widely used. However, many users do not understand the difference between drag chain and ordinary cable. Let's take ATO drag chain as an example to explain the difference between drag chain and ordinary cable from three aspects: conductor, insulation and sheath.

The conductor of drag chain uses finely stranded copper wires, while ordinary cables also use thin copper wires. For the core wires of the same cross-section, the diameter of the monofilament in the drag chain conductor is smaller than that of ordinary cables, in order to ensure the physical properties of the conductors. The performance and electrical performance are stable. Generally, a multi-threaded 4N conductor is used. The conductor is bright and bright, and has good toughness; the resistivity is low, and the wire does not heat up under the rated load for a long time.

The insulation requirements of drag chain are very high, with strong hardness, adhesion resistance, and good toughness. The insulation of ordinary cable is to use non-conductive materials to isolate or wrap the charged body.

The sheath of drag chian generally requires tensile strength, strong abrasion resistance, adhesion resistance, and high toughness, while ordinary wire and cable have lower requirements in this respect.

What are the advantages of drag chain cables?

First of all, in terms of flexibility, drag chains are more flexible than ordinary cables. Although the monofilament diameter of the drag chain cable conductor is small, in order to protect the conductor, an insulating material with resistance to mechanical fatigue and a certain strength must be selected. The requirements of tensile resistance, bending resistance, strong wear resistance, anti-blocking, and high toughness also determine that the protective cover material should also have a certain degree of hardness. Therefore, the flexibility of the drag chain is high flexibility, not high flexibility.

Secondly, in the selection of materials, the towline is better than ordinary cables. The drag chain conductor adopts high-purity oxygen-free copper wire, which is bright in color and more regular in shape. The drag chain is made of virgin material, with high strength, good bending and tear resistance.

Finally, in terms of service life, the service life of towline is longer than that of ordinary cables. When the drag chain has a small bending radius and a very fast moving speed, ordinary wires and cables sometimes cannot be used at all. Even in the case of large-radius installation and wiring and low-speed and low-frequency, there is a big gap between the mechanical bending service life of drag chain and ordinary cable.

The difference between drag chain and ordinary cable is analyzed through three aspects of conductor, insulation and sheath. Compared with ordinary cable, the advantage of towline cable is an ideal choice for mobile use equipment.