Gauss Meter Troubleshooting

A Gauss meter is a commonly used measuring instrument to detect the strength and direction of magnetic fields. Whether in scientific research, medicine, engineering, or other fields, Gauss meters play a vital role. However, like any electronic device, a gauss meter can experience a variety of malfunctions and problems. This ATO online shop article will look at the structural features, common test methods, and troubleshooting methods of Gauss meters to help you better maintain and use this critical instrument.

Construction Features of Gauss Meters

Before troubleshooting a gauss meter, we first need to understand the structural features of a gauss meter, which will help us better understand the possible causes of the malfunction. Gauss meters typically have the following key components and features.

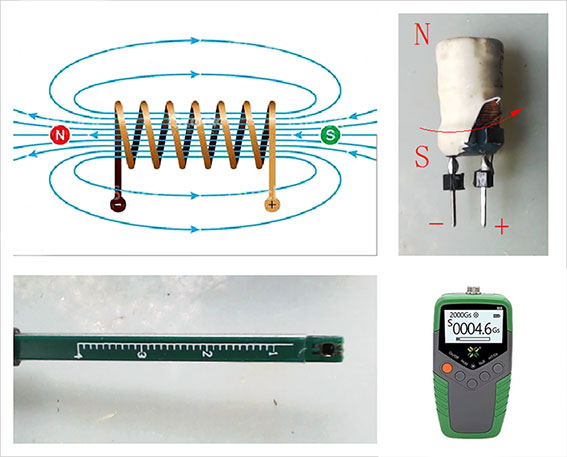

- Magnetic Field Sensor: The core component of a gauss meter is a magnetic field sensor, which can be based on the Hall effect, magnetoresistance, or other principles. The magnetic field sensor is used to measure the strength and direction of the magnetic field.

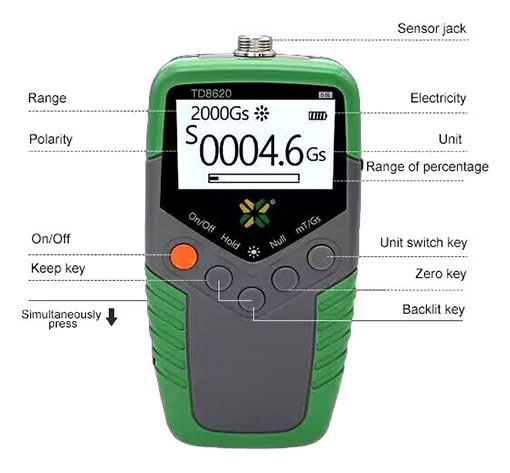

- Display: Gauss meters are usually equipped with either a digital or analog display to show measurement results. Digital displays provide more accurate readings, while analog displays can be used to observe trends in the magnetic field.

- Control Buttons: Gauss meters are usually equipped with several control buttons that are used to select the measurement range, units, calibration, and so on. These buttons help the user to make settings according to specific needs.

- Power Supply: A gauss meter requires a power supply, usually batteries or an external power adapter. Ensuring that the power supply is working properly is critical to the accuracy of the gauss meter.

- Interfaces and Communication Options: Some advanced gauss meters have interfaces and communication options such as USB, RS-232, or Bluetooth to transfer data to a computer or other device for further analysis.

Test Methods for Gauss Meters

Before troubleshooting a gauss meter, it is necessary to perform the proper tests to confirm that a problem exists. Here are some common ways to test a gauss meter.

Calibration Test: Calibration is a critical step in ensuring the accuracy of your gauss meter's measurements. It is important to perform calibration tests regularly to ensure the accuracy of your gauss meter. Calibration usually involves placing the gauss meter in a known magnetic field and then comparing the readings to the known values. If the gauss meter displays values that deviate from the known values, calibration may be necessary.

Zero Field Test: A gauss meter can be tested under zero-field conditions to confirm that it reads zero magnetic fields correctly. This usually involves placing the gauss meter in an environment with a very weak or almost zero magnetic field and then observing the readings. If the gauss meter shows a non-zero value, it may need to be repaired or adjusted.

Magnetic Field Orientation Test: Testing whether a gauss meter accurately measures the direction of a magnetic field can be accomplished by rotating the gauss meter in a known direction of the magnetic field and recording the reading. This helps to confirm that the directional sensitivity of the gauss meter is normal.

Magnetic Field Strength Test: Testing whether a gauss meter accurately measures the strength of a magnetic field can be done by placing the gauss gauge in a known magnetic field and recording the reading. If the reading does not match the known strength, it may need to be calibrated or repaired.

Troubleshooting the Gauss Meter

- Power Problems: If the gauss meter fails to turn on or displays a low battery warning, first check the battery status. Make sure the batteries are properly installed and have sufficient charge. If using an external power adapter, make sure the power supply is connected properly.

- Calibration Problems: If the gauss meter is displaying abnormal readings, first perform a calibration test to ensure that the gauss meter is properly calibrated. If calibration is not working properly, follow the calibration procedure provided by the manufacturer.

- Sensor Problems: If the sensor of the gauss meter is damaged or contaminated, it may cause inaccurate readings. Check that the sensor surface is clean and free of scratches or damage. Clean the sensor or replace damaged parts if necessary.

- Circuitry Problems: Circuitry problems inside the gauss meter may result in abnormal readings or failure to operate. Check connections, solder joints, and components on the circuit board to make sure they are not loose or damaged. If a problem is found, it may be necessary to repair the circuitry or replace damaged parts.

- Software Problems: Some advanced Gauss meters have built-in software that may cause software problems. If the gauss meter is not reading properly, try resetting or updating the software, or contact the manufacturer for support.

- Environmental Interference: The gauss meter may be subject to interference from external magnetic fields, resulting in inaccurate readings. Ensure that measurements are taken under conditions free from external magnetic field interference, or use magnetic field shielding to minimize interference.

Gauss meters have important applications in several fields, so it is critical to understand their construction features, testing methods, and troubleshooting. With proper maintenance and troubleshooting, you can ensure the accuracy and reliability of your gauss meter for a variety of applications. When using a gauss meter, always consult the user manual and technical support provided by the manufacturer to better solve problems and utilize the capabilities of the gauss meter.