How to Replace Sealing Ring of Magnetic Powder Clutch?

The magnetic powder clutch is based on the electromagnetic principle and the use of magnetic powder to transmit torque. It has a linear relationship between the excitation current and the transmission torque. It can transmit a certain torque regardless of the slip. It has the advantages of pollution, no noise, no shock and vibration, energy saving, etc. Magnetic particle clutch is a multi-purpose and superior automatic control element. However, how to replace sealing ring of water-cooled magnetic powder clutch?

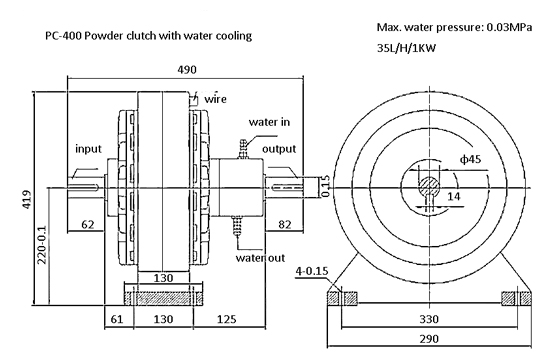

ATO water-cooled magnetic power clutch dimension

Unit: mm

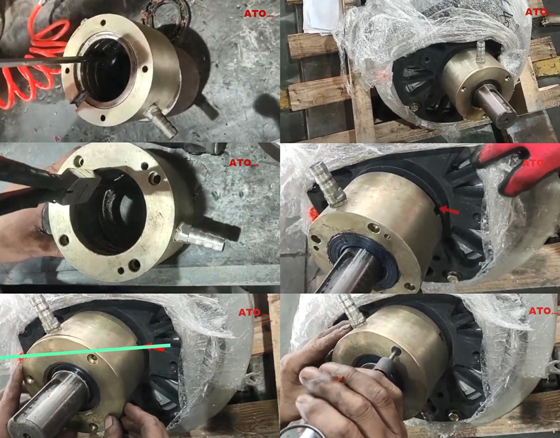

This is the sealing ring that needs to be replaced.

Steps to replace sealing ring

- Remove the sealing end cap.

- Remove the fixing bolts.

- Knock of the outermost sealing ring.

- Remove the sealing ring fixing buckle.

- Remove the innermost sealing ring.

- Apply sealing oil to the sealing ring.

- Install the sealing ring fixing buckle.

- Put the new seal back into the water exchanger.

- Install the magnetic powder clutch.

Pay attention to the location of the drip hole. - Reattach the retaining bolt.

The position of the drip hole is at the same level as the red terminal. - Install the end cover back and complete the replacement of sealing ring.

You could watch the video below to know more about water-cooled magnetic powder clutch sealing ring replacement. What’s more, ATO has 6Nm, 25Nm, 50Nm, 100Nm, 200Nm, 400Nm magnetic particle and powder clutch for your choices, shop now!