How to Use Handheld Soldering Gun?

Soldering gun is a commonly used welding tool, which can be used to weld various metal materials, such as iron, copper, aluminum and so on. Welding with a soldering gun requires attention to some usage methods and skills. The following will introduce the usage and precautions of the soldering gun in detail.

Operation method

Before starting the machine, please check the power supply, whether the gas source is normal, and whether there is dust on the soldering gun head.

Start up

The start-up sequence of the handheld laser welding machine is to turn on the emergency stop switch first, then turn on the power of the machine, the system power, and the laser power in order to turn on the water tank for 30 seconds.

Welding preparation

Turn on the gas source switch, and set the laser parameters on the control panel. Once you're ready, find the material you want to weld.

End of welding

When the welding is over, first turn off the laser power, then turn off the system power and the machine power in turn, and the soldering gun head should be placed on the equipment.

Precautions

Hand-held soldering gun is a common welding tool, which can be used for welding a variety of materials, such as steel, aluminum alloy, copper, etc. The use of hand-held soldering gun is relatively simple, but there are some safety precautions that need to be paid attention to.

We need to do a series of checks before operation. First of all, we have to carefully check whether the reflective lens of the handheld laser welding machine is clean. If there is some dust on it, it must be cleaned in time, otherwise the contaminated lens may explode during the work process. After checking the lens, we have to do other corresponding adjustments. Other adjustment work is also relatively simple, but also to check whether there are loose parts in other places. After the inspection is completed, turn on the machine, which can ensure that the welding machine can run more smoothly during operation.

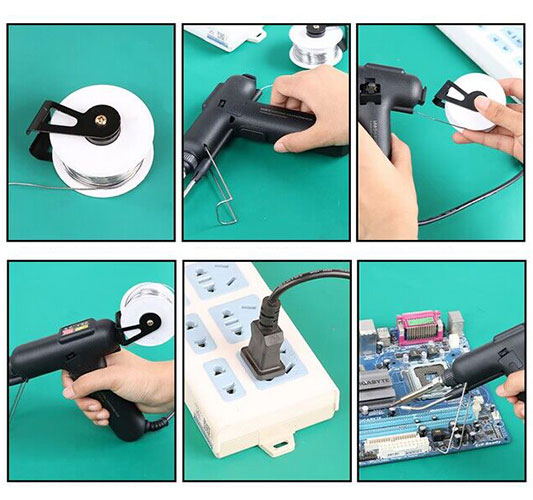

Need to prepare welding materials and tools. Welding materials include welding wire, electrode, gas, etc. Tools include pliers, brushes, wire brushes, etc. Welding materials and tools need to be prepared before welding for use during welding.

Next, the auto electric handheld soldering gun needs to be plugged into a power outlet and the welding current adjusted. Generally speaking, the welding current needs to be adjusted according to the type and thickness of the welding material. If the current is too large, it will cause the welding material to melt excessively, which will affect the welding quality. If the current is too small, it will cause weak welding.

The material then needs to be placed where it needs to be welded, and the wire or rod is held onto the hand torch with pliers. Then aim the welding gun at the welding material and press the trigger to start welding. During the welding process, it is necessary to keep the soldering gun at a certain angle and distance to ensure the welding quality. After the welding is completed, the material needs to be cleaned and polished to achieve a better welding effect.

If it is found that the effect and efficiency are not as good as before during the processing, the first thing we need to consider is whether the material of the laser welding auto electric handheld soldering gun has changed, because the considerations for processing different materials are also different. If this is the reason, we can adjust the parameters of each item, and then do some tests to see the situation.

We need to ensure that the working environment of the handheld laser welding machine has good lighting and cleanliness. Although everyone may think that the working environment of the laser welding machine does not need to be particularly good, only a better environment can further improve work efficiency. In order to give full play to the advantages of hand-held soldering guns, we should try our best to avoid some bad situations in the production process to reduce production costs.

When using a soldering gun, the operating specifications should be followed, and the parts of the soldering gun should not be disassembled at will to avoid unnecessary damage. After the soldering gun is used for a period of time, a large amount of dust and welding slag will accumulate, which will affect the working efficiency of the soldering gun. Therefore, the soldering gun should be cleaned regularly to ensure the working efficiency of the soldering gun.

The service life of the welding gun is also related to the quality of the welding rod. Using better quality electrodes can prolong the service life of the soldering gun. After using the soldering gun for a period of time, check all parts of the soldering gun regularly, and repair or replace it in time if any problem is found.

After using the soldering gun, put the soldering gun in a dry place, avoid the soldering gun from contact with moisture or humid environment, so as not to cause damage to the soldering gun. Internal heating soldering gun are mechanical devices. If overused, it can cause wear and damage to the device. Therefore, excessive use should be avoided when using a soldering gun to prolong the service life of the soldering gun. The use efficiency of the soldering gun is also related to the power supply. Using a power supply with too high or too low voltage will reduce the efficiency of the soldering gun or even damage the soldering gun. Therefore, a suitable power source should be used when using a soldering gun.

The correct welding technique can not only improve the welding quality, but also reduce the wear and tear of the soldering gun. Therefore, attention should be paid to proper welding technique when using a soldering gun. Before using the handheld soldering gun, you need to wear protective equipment, such as welding gloves, welding mask, protective shoes, etc. These equipment can effectively protect the safety of welders.

In short, if the soldering gun is used correctly, the service life of the soldering gun can be extended and the use efficiency of the soldering gun can be improved. Therefore, the above points should be paid attention to when using the soldering gun to ensure the normal use of the soldering gun.