Vibration Motors

20W 24V DC Brushless Vibration Electric Motor with Controller

2kW (2.5 hp) 3 Phase AC Vibration Electric Motor, 220V/380V

40W 24 Volt DC Brushed Vibrating Electric Motor with Controller

20W 12 Volt DC Brushed Vibrating Electric Motor with Controller

100W 12 Volt DC Brushed Vibrating Electric Motor with Controller

100W 24 Volt DC Brushed Vibrating Electric Motor with Controller

160W 24 Volt DC Brushed Vibrating Electric Motor with Controller

40W 12V 3000rpm DC Brushed Vibration Motor with Speed Controller

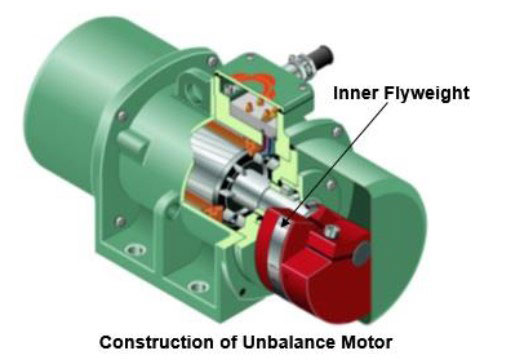

Vibration motor is on both ends of the rotor shaft installed a set of adjustable eccentric block, the centrifugal force generated by high speed rotation shaft and eccentric block vibration force. ATO has AC vibration motor, DC brushless vibration motor and explosion proof vibration motor, power can be selected from 10W, 50W, 100W to 5.5 kW, 3000rpm-7000rpm rated speed. DC brushless vibration motor with speed dispaly controller, ATO vibration motor have high efficiency, energy saving, stable running and long service life. Special voltage, speed, power please contact us, can be customized.

3 Ways to adjust vibration motor vibration

Due to the good use of vibration motors in material classification and processing, vibration motors are constantly being introduced in industries such as mining, metallurgy, chemical industry and building materials. However, many users do not know how to adjust the vibration motor when using vibration motors. Based on years of production experience, we summarizes the following 3 methods to adjust the vibration of vibration motor.

- Adjust the vibration of the vibration motor by yourself. If you want to adjust by yourself, ATO vibration motor recommends that you understand the working principle and structure of the equipment before adjustment, and at the same time master certain operation foundations and maintenance common sense to avoid failure or damage due to insufficient debugging.

- Adjust according to the actual vibration requirements during use. When the vibration motor runs for a period of time, if its vibration frequency cannot meet the needs of use, the vibration motor manufacturer recommends that you debug in strict accordance with the actual needs of the equipment.

- Look for the technicians of the vibration motor manufacturer to adjust the vibration. Many vibration motor after-sales services include vibration adjustment and other content.

How to select a right vibration motor?

Speed of vibration motor

Vibration motor is the power source of vibration mechanical equipment. It has high speed and small amplitude. Therefore, according to the different purposes of vibration, we first select the speed of the motor: The rotation speed of AC vibration motor at the frequency of 50 Hz is 3000 rpm/ min (2 poles), 1450rpm / min (4 poles) and 980 rpm / min (6 poles), and the rotation speed of DC vibration motor is 3000-7200 RMP / min. They produce double amplitudes: 2-4mm for 2-pole motors, 4-6mm for 4-pole motors, and 6-12mm for 6-pole motors.

- For screening, long-distance transportation and spiral lifting of materials, 6-level vibrating motor is used.

- Four- level vibration motor is used to feed, dehydrate and polish materials.

- Two-level vibration motor is used to vibrate and activate the materials.

Design form of vibration motor & Quantity required

- Two vibration motors are used to linear vibrating screen, conveyor and screw hoist.

- Circular vibrating screen and rotary vibrating screen use one vibration motor.

- For vibrating platform and warehouse wall vibrator, one, two, four, six, eight or more vibrator motors can be used at the same time.

Weight of vibrating mechanical equipment

- If the excitation force of the selected vibration motor cannot meet the requirements, its amplitude is not enough, the material does not run, which will affect the output, and also cause the vibration motor overload and scalding, which will seriously damage the motor.

- When the vibration motor leaves the factory, the exciting force is not full. Generally, it is adjusted to 70% of the maximum exciting force, which can extend the service life of the motor bearing and avoid the motor coil heating, so as to achieve the best use effect.

- The total exciting force of the vibration motor should be greater than 1 times of the total weight of the vibrating object.

- The higher the power of the vibration motor, the greater its excitation force. The excitation force is expressed in kN, and 1kN about 100kg.

- The exciting force of the vibration motor is too large, which is more than one time of the total weight of the vibration body, it will not only increase the cost of the equipment, but also cause damage to the vibration machinery and equipment, which will tear the weld, deform the steel plate and swing.

Usage condition

The exciting force of motor should be reduced in high altitude area, or the VFD should be installed to control. That is to say, the exciting force of the vibrating motor should be adjusted at 50%.

How to install the vibration motor?

Vibration motor is a power source and vibration source combined as one of the exciting source. Its exciting force is easy to use. They can be applied to general vibration machinery, such as: vibration crusher, vibrating screen extension machine, vibration baler, vibration shakeout machine, vibration molding machine, vibration pile driver, vibration hoist, vibration filling machine, silo vibration arch broken anti-occlusion device and so on. They are widely used in hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, light industry and other industrial sectors. Watch the following video to learn more about how to use a vibration motor.

The role of the eccentric block of the vibration motor

The vibration motor is equipped with a set of adjustable eccentric blocks at both ends of the rotor shaft, and the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block is used to obtain the exciting force. The vibration motor has a wide frequency range. Only by properly matching the excitation force and power can the mechanical noise be reduced.

The vibration motor is the core part of the vibration screening equipment. The excitation source combines the power source and the vibration source. It is a set of adjustable eccentric blocks installed at both ends of the rotor shaft. It will use the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block to obtain the exciting force. In addition, the vibration motor has a high utilization rate of excitation force, low energy consumption, low noise and long life. The excitation force of the vibration motor can be adjusted steplessly and is easy to use.

How to adjust the eccentric block of a vibration motor?

1. Change the phase angle of the weight above and below the vibration motor, which can change the trajectory and residence time of the material on the screen, so that the screen machine can adapt to the required separation state of various materials. Various changes such as separation efficiency and network speed should be adjusted to a better state.

2. The upper weight cannot be adjusted. At this time, it is firstly required to open the adjustment hole at the bottom of the device base, and then loosen the lower weight fixing bolt. According to the trajectory of the screened material, it is required to adjust the phase angle of the upper and lower weights in the direction opposite to the discharge port. Then, please tighten the fixing bolts, put a small amount of material on the surface of the screen, let the screen run, and check the movement track of the material on the surface of the screen. If the processing parameters achieve good results, please stop fixing the bolts and stop adjusting (remember to tighten the fixing bolt).

3. Adjust additional weights: There are additional weights on the sides of the upper and lower weights, and their role is to increase or decrease the exciting force of the screen. You can increase or decrease other weights based on factors such as the number of layers in the device, the weight of the material, and so on. Non-professionals should not add or subtract extra weight at will.

Vibration motor troubleshooting

If the motor does not work after startup, it should be checked:

- Whether the power supply is lack of phase

- Whether the motor is out of phase

- Whether the shield is damaged and rubbed against the eccentric block

After starting up, the motor is noisy and hot, it should be checked:

- Whether the roughness of the contact surface between the vibrating machine and the motor foundation meets the installation requirements

- Whether the anchor bolt is tight or not

- Whether the vibration acceleration of the main engine meets the use requirements

When you adjust the eccentric block, you should check whether the eccentric blocks at both ends of the shaft are adjusted symmetrically if the amplitude changes abnormally.

In the vibration equipment with two vibration motors working at the same time, when the phase rotation does not meet the requirements, the phase sequence of one vibration motor must be adjusted, not the phase sequence of the total power supply of the two vibration motors.

Filter by:

Clear All