Operating Steps of Start and Stop Pressure Transducers

In normal inspection and maintenance of pressure transducer, zero calibration and periodical blowdown of the pressure transducer would involve the starting and stopping operations. So correctly start and stop the pressure transducer is also one of the required skills. This paper describes the specific start and stop operating steps of pressure transducer.

1. On-site Installed Pressure Transducer

The installation method of on-site installed pressure transducer and spring pressure gauge are nearly the same, namely there's only one sampling valve. Sometimes, there's also a drain valve.

Note: On-site installed pressure transducer mentioned here mainly refers to the screw mounted transducer, such as the monocrystalline silicon pressure transducer.

- Stop Method of On-site Installed Pressure Transducer

When stopping, close the sampling valve of on-site installed pressure transducer and open the drain valve slowly to remove the measured pressure. If there's no drain pressure, the pressure can only be relieved by slowly loosening the joint threads of pressure transmitter. When operating, be careful of medium pressure injury. - Start Method of On-site Installed Pressure Transducer

When starting, open the sampling valve of on-site installed pressure transducer.

2. Remote Installed Pressure Transducer

There are at least three valves and connecting pipe connecting with the remote installed pressure transducer, the sampling valve is used for sampling and cutting the process, the medium drain valve is used to flush the pipe and remove condensate or gas from the pipe. The globe valve connecting the connecting pipe and pressure sensor is also called second valve.

- Stop Method of Remote Installed Pressure Transducer

When stopping, close the second valve of pressure transducer and then relieve the pressure through the drain valve or exhaust valve on the pressure transducer's measuring room or the blow-down valve on connecting pipe. If necessary, close the sampling valve. If the pressure transducer has sealing liquid, the blow-down valve can't be opened randomly to relieve the pressure. - Start Method of Remote Installed Pressure Transducer

When starting the transducer used for general measuring medium, open the second valve. If the vapor pressure measurement of connecting pipe has been exhausted, close the second valve and blow-down valve first and then open the sampling valve, open the blow-down valve to flush the connecting pipe. After closing the blow-down valve, open the second valve after waiting for more than half an hour till the connecting pipe is full of steam condensate. The exhaust the air through the exhaust valve on the pressure sensor's measuring room. When performing the above operations, relevant control system shall be switched to manual operation and the process operator shall be notified.

3. Operating Steps of Start and Stop a Differential Pressure Transducer

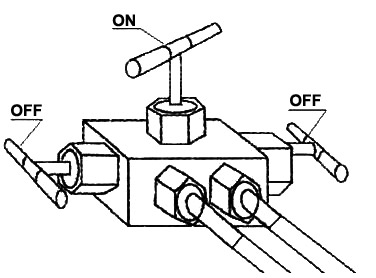

There are at least five valves connecting with the differential pressure transducer, among, two sampling valves are used for sampling and cutting off the process media, two blow-down valves are used to flush the connecting pipe or remove condensate or gas from the connecting pipe. The connecting pipes are connected with the differential pressure transducer through three-valve group or five-valve group, and the starting and stopping of differential pressure transducer are mostly operated on the three-valve group.

- Stop Method of Differential Pressure Transducer

When closing the differential pressure transducer, the steps for closing the three-valve group are as follows: close the negative pressure valve first, then open the balanced valve, and finally close the positive pressure valve. If the differential pressure transducer is out of operation for a long time, both positive and negative pressure valves of primary valve and three-valve group should be closed, the balanced valve should be opened to ensure equal pressure on both sides of the transducer's measuring room, in a balanced state.

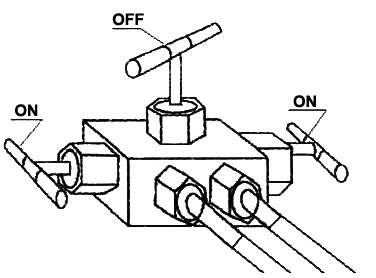

- Start Method of Differential Pressure Transducer

When starting the differential pressure transducer, the steps for opening the three-valve group are as follows: open the positive pressure valve firstly, then close the balanced valve, and finally open the negative pressure valve.

When starting or stopping the differential pressure transducer for steam flow measurement, the differential pressure transducer with isolator, and the liquid level differential pressure transducer with a balanced container, the positive pressure valve/negative pressure valve/balanced valve cannot be opened at the same time when operating the three-valve group. Because even if it is opened in a short time, the condensate water in the balanced container and the isolation fluid in the isolator may run off, resulting in the incorrect display of meter, and even the differential pressure transducer cannot be put into operation in serious cases. When necessary, the drain valve and exhaust valve on the measurement room of differential pressure transducer shall be used to remove the air or condensate water.