Piston Air Motor

1/8 hp Piston Air Motor, 1100 rpm, 202 L/min

1/6 hp Piston Air Motor, 1000 rpm, 211 L/min

1/4 hp Piston Air Motor, 900 rpm, 259 L/min

1/3 hp Piston Air Motor, 900 rpm, 267 L/min

1/2 hp Piston Air Motor, 750 rpm, 397 L/min

3/4 hp Piston Air Motor, 700 rpm, 507 L/min

1.5 hp Piston Air Motor, 360 rpm, 985 L/min

Piston air motor is a kind of air motor that converts the linear motion of several pistons into rotary motion through a crank or a swash plate. ATO.com online store offers pneumatic piston air motor of rated power from 1/8 hp to 1.5 hp, wide range air consumption from 202 L/min to 985 L/min, rated speed 360 rpm to 1100 rpm. The piston type air motor has advantages of small size, light weight, low noise and long service life. The piston air motor is mainly used in mining machinery, and can also be used as drive motors for conveyor belts, etc.

Features of Piston Air Motor:

- Piston air motor suits for various applications. There is a lot of resistance and variability such as winch and high capacity hoist.

- Piston pneumatic motor will not burn out. Air motors can be stalled or overloaded for long periods without damage.

- Great for harsh environments. No heat build up or sparks make air motors ideal for use in flammable or explosive applications.

- Instantly reversible. A four-way valve allows instant motor reversal (on reversible units) with the turn of a valve.

- Cool Running. A running air motor expands air, allowing motors to operate in temperatures up to 150F and some motors up to 300F with special grease, lube and seals.

- Compact and Portable. Get maximum horsepower in minimum size.

- Variable speed. You may utilize a wide range of speeds by using a simple valve on your input air supply line.

- No shock starts. Air cushioned start-up cuts stress to your equipment.

Piston Air Motor vs. General Motor:

- Piston air motor with small volume produces high power.

- High adaptability, small temperature rise, speed can be changed with the load, until the overload stop without any damage to the piston pneumatic motor, so the choice can be considered to use a lower safety factor.

- Air motor with emergency start, emergency stop, especially suitable for frequent start occasions, and reversing is very easy.

- Simple stepless speed regulation, from zero to maximum, flexible operation.

- Piston air motor has large starting torque and can start with load.

- Simple structure, long service life of pneumatic motor.

- Piston air motor is not affected by the external environment, even in water, dust, humidity, dirt and other harsh environment, because the internal pressure of the pneumatic motor is greater than the external pressure.

How Does Piston Air Motor Work?

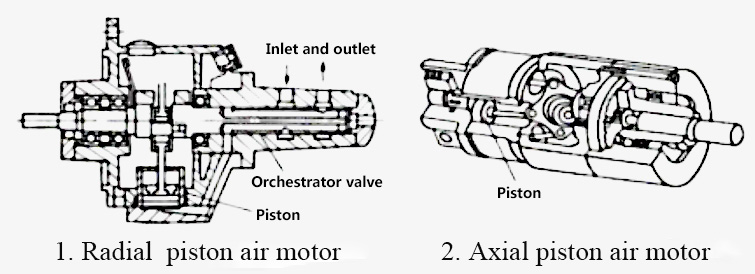

The schematic diagram of the structure of a piston type air motor is a pneumatic motor that converts the linear motion of several pistons into a rotary motion through a crank or a swash plate. Its structure has two kinds of radial piston type and axial piston type.

Figure 1 shows the structural principle of the most common radial piston air motor. The working chamber is composed of pistons and cylinders. Three to six cylinders are distributed radially around the crankshaft, and each cylinder is connected to the crankshaft through a connecting rod. The compressed air distribution valve supplies air to each cylinder in sequence, and the compressed air pushes the piston to move and drives the crankshaft to rotate. When the valve is turned to a certain angle, the remaining air in the cylinder is discharged through the exhaust port. Changing the direction of intake and exhaust can realize the forward and reverse conversion of the air motor.

Figure 2 shows the structural principle of an axial piston air motor. Cylinders are evenly distributed in the axial direction. The pistons of the cylinders make reciprocating linear motions in turn under the action of the input compressed air, and the linear motion is transformed into the rotary motion of the output shaft through the action of the swash plate.