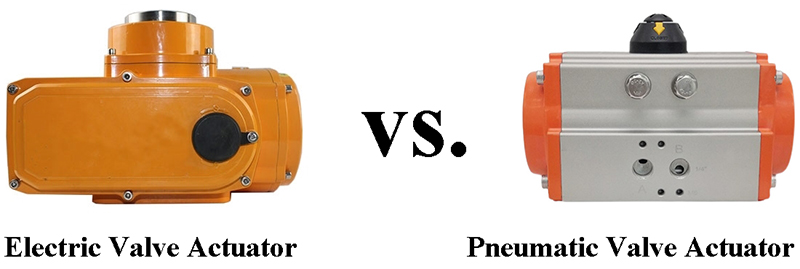

Pneumatic Valve Actuator vs. Electric Valve Actuator

What is a pneumatic valve actuator?

Most of the actuators used in industrial control applications today are pneumatic valve actuators, because the air source is used as power, which is more economical than electric and hydraulic, and the structure is simple, easy to master and maintain. From the point of view of maintenance, pneumatic actuators are easier to operate and calibrate than other types of actuators, and they can also be easily interchanged on the spot. Ideal for flammable and explosive environments when using positioners. Therefore, although the application range of electric control valves is becoming wider and wider, in the chemical field, pneumatic control valves still occupy an absolute advantage.

What is an Electric Valve Actuator?

Electric valve actuators are mainly used in power plants or nuclear power plants because a smooth, stable and slow process is required in high pressure water systems. The main advantages of electric valve actuators are high stability and constant thrust that can be applied by users. The thrust generated by the maximum actuator can be as high as 225,000kgf. Only hydraulic actuators can achieve such a large thrust, but the cost of hydraulic actuators is higher than that of electric actuators. The anti-deviation ability of the electric actuator is very good, and the output thrust or torque is basically constant, which can well overcome the unbalanced force of the medium and achieve accurate control of the process parameters, so the control accuracy is higher than that of the pneumatic actuator. If it is equipped with a servo amplifier, it is easy to realize the exchange of positive and negative effects, and it is also possible to easily set the state of the valve position of the off-signal. When a fault occurs, it must stay in the original position, which is impossible for pneumatic actuators. The device must be kept in place by means of a combined protection system.

Difference between Electric Valve Actuator and Pneumatic Valve Actuator

Overload resistance and service life

Electric actuators can only be used for intermittent operation and are therefore not suitable for continuous closed-loop operation. Pneumatic actuators, on the other hand, are overload resistant and maintenance-free throughout their service life. No oil change or other lubrication is required. With a standard service life of up to one million switching cycles, pneumatic actuators are superior to other valve actuators.

Safety

Pneumatic actuators can be used in potentially explosive situations, while electric actuators are not easy to use in potentially explosive situations and are expensive.

Anti-overload capability

In the case of increased torque or special demands on the applied force, electric actuators will quickly reach the torque limit. Especially when the valve actuator is not opened regularly or closed for a long time, the advantage of the overload resistance of pneumatic actuators is obvious, because deposits or sintering can increase the starting torque. Using pneumatic components, it is easy to increase the working pressure as well as the force or torque.

Economy

In water and wastewater technology, most valve actuators are operated in on/off mode or are even designed for manual operation, so pneumatic components open up important prospects for rationalization. Compared with pneumatic actuators, if electric actuators are used, monitoring functions such as over temperature monitoring, torque monitoring, switching frequency, maintenance intervals must be designed in the control and test system, which results in a large number of line inputs and outputs. Apart from end position sensing and air supply handling, pneumatic actuators do not require any monitoring and control functions. The cost of pneumatic actuators is low, so it is more important to automate manual valve actuators.

Assembly

The installation of the pneumatic actuator on the valve drive head and the connection and drive of the air source processing device can be easily realized. In addition, the maintenance-free design of the pneumatic actuator ensures that it is easy to install and operate.

Element

Pneumatic components have high vibration resistance, are strong and durable, and are generally not damaged. Even high temperatures will not damage corrosion-resistant components. Electric actuators are composed of a large number of components, which are relatively easy to damage.