Servo Drive System vs. Variable Frequency Drive

Servo drive systems and variable frequency drives are two different types of drive systems, which have different applications and characteristics in the field of industrial automation. ATO online shop will go into detail about this topic.

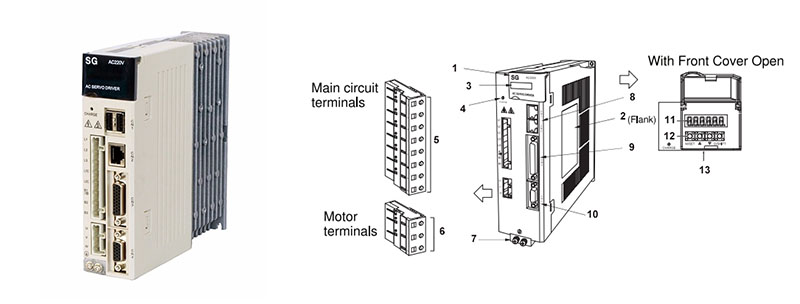

Servo Drive

A servo drive is an integral part of a servo system that consists of a motor, a controller, a feedback device, and of course- a servo drive. In layman's language, a servo drive is a part of the servo system that receives a particular command from a control system, amplifies it, and transmits the current to a servo motor in the system. The servo motor produces a motion, tailored to the command it has received. The command signal usually represents some of the physical variables such as torque, velocity, and the desired position.

The servo motor is equipped with a sensor(Encoder ) that reads the current position of the motor and reports it back to the servo drive. when the feedback is received, a servo drive compares the motor status and position with the commanded variables. If there's a deviation from the given commands, the servo drive alters the frequency, voltage, or any other variable to correct the deviations.

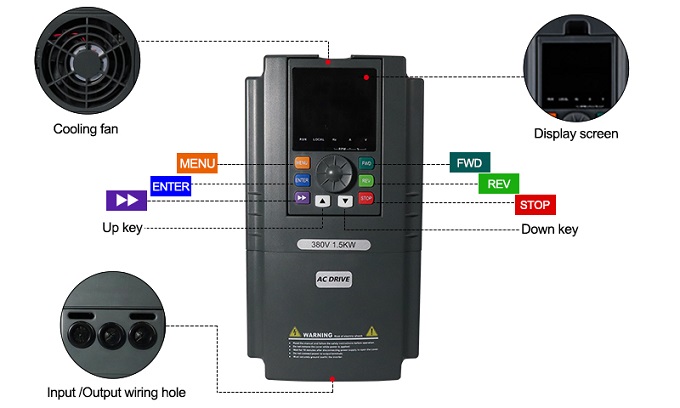

Variable Frequency Drive

A Variable-Frequency Drive (VFD) is also a motor control unit, but it works in a different way than a servo drive. The VFD is a type of motor controller that works in conjunction with an electric motor by varying the variables such as voltage and frequency supplied to the electric motor. While a servo drive needs a command signal given to the motor to compare the real and desired position of the motor, a vfd directly controls the voltage and frequency supplied to the motor. VFDs are also known by other names such as AC drive, adjustable-frequency drive, and inverter.

When it comes to the motor's speed (RPM), a variable that is directly related is the frequency in Hz. The lower the frequency is, the lower the speed of the motor is, and vice versa. Sometimes, the electric motor doesn't need to run at full speed and vfd can come in handy since it allows you to manipulate the frequency and voltage. If you don't need full speed, you can decrease the frequency and voltage of the motor to suit your needs. This will also save the electric motor from potential malfunction and extend its life.

Generally, variable frequency drives are used for reducing energy consumption thus reducing the energy costs of an electric motor. These motors proved to be very good when it comes to tight process control and are used everywhere from small appliances to large electronic systems, for controlling electric motors.

Servo Drive System vs.Variable Frequency Drive

The Servo Drive System is typically employed in applications demanding high precision in terms of position, speed, and force. Known for its outstanding accuracy and responsiveness, it achieves high-performance closed-loop control. Utilizing closed-loop control, the system adjusts itself by continuously monitoring the feedback mechanism, such as encoders, to ensure precise position and speed control. The servo system finds extensive applications in fields that require high precision and performance, such as CNC machine tools, robotics, and precision machining.

In contrast, the Variable Frequency Drive (VFD) is primarily used to adjust the operating frequency of a motor, thereby controlling its speed. As an open-loop control system, VFD proves practical in applications that do not necessitate extremely high precision. It enhances system efficiency by adjusting the power frequency to reduce motor speed during startup and operation. VFDs are widely applied in scenarios requiring speed control, such as ventilation, pumps, and conveyors, where the demand for precise positioning and high-performance control is relatively lower.

Therefore, when choosing between a servo drive system and a variable frequency drive, considerations should be based on specific application requirements. If precision and high-performance control are essential, especially in fields like robotics and CNC equipment, the servo drive system may be more suitable. On the other hand, for routine speed control applications, a Variable Frequency Drive might be a more economical and practical choice.