Servo Motor Basics & Working Principle

Servo motor basics

What is a servo motor? Servo motor is the motor which controls mechanical components operation in servo system. Servo motor can convert voltage signal to torque and speed, then to drive the control object. The control speed and position accuracy is very high. In auto control system, servo motor can response rapidly as executing component, convert the receiving electrical signal to angular displacement or angular velocity output of motor axis. The main feature is, when signal voltage is zero and no self-rotation, rotation speed will descend at even speed along with the torque increasing. Servo motor has 2 types, DC servo motor and AC servo motor.

DC servo motor

DC servo motor, which includes stator, rotor core, motor rotating shaft, servo motor winding commutator, servo motor winding, speed motor winding, speed motor commutator, all rotor core is made of silicon steel punching sheet laminated press fixed on the motor rotating shaft.

The motor which is used as a DC servo motor generally have a separate DC source in the field of winding and armature winding. Control can be archived by controlling the armature current or the field current. Depending on the application, the control shall be applied to the DC servo motor. Due to low armature inductance, dc servo motors provide very accurate and fast response to start or stop command signals. DC servo motors are used in similar equipment and computer numerical control machines. Actuators in various digital control systems. Power drives that require precise control of constant speed or require precise control of speed change curves.

AC servo motor

AC servo motors are also brushless motors, which are divided into synchronous and asynchronous motors. At present, synchronous motors are generally used in motion control. They have a large power range and can achieve great power. Large inertia, low maximum rotation speed, and rapid decrease as the power increases. Therefore, it is suitable for low-speed and smooth-running machines.

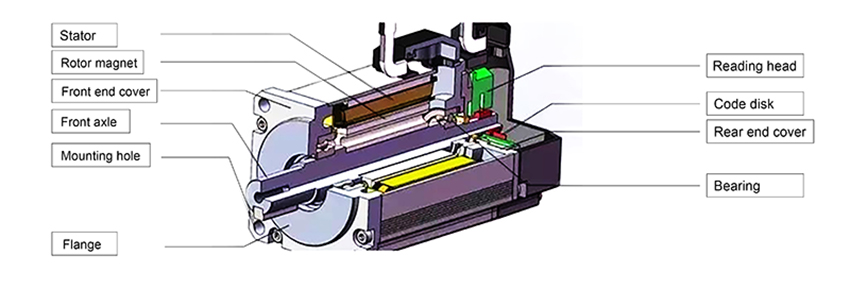

The structure of AC servo motor can be divided into two parts, namely stator part and rotor part. The stator structure is basically the same as that of the rotary transformer, and the two phase windings with 90 degrees of electric angle are placed in the stator core. One group is the exciting winding and the other group is the control winding. AC servo motor is a two-phase AC motor.

AC servo motor applications

Material Measurement

Powder material measurement, commonly used screw measurement method. Through the screw rotation of the number of turns to achieve the purpose of measurement. In order to improve the accuracy of measurement, the screw speed is adjustable and the position is accurate. If the ac servo motor is used to drive the screw, the advantages of high control precision and good torque frequency characteristics of ac servo motor can be achieved fast and accurate measurement. For the measurement of viscous material, AC servo motor can be used to drive the gear pump, through a pair of gear pump meshing to measure.

Horizontal Sealing Device

The horizontal sealing device is an important mechanism in bag-making automatic packaging machine. It not only requires accurate positioning, but also requires that the linear speed of the horizontal sealing wheel be equal to the speed of the film. After rolling, the rotational speed of the horizontal sealing wheel should increase, that is, phase separation at a faster speed.

Material delivery

The working mode of packaging machinery for material delivery has intermittent type and continuous type. In the intermittent mode of material supply and delivery, such as in the intermittent bag-making machine. If the AC servo motor is used to drive the pulley, the distance, running time and stopping time of the AC servo motor can be set in advance in the controller. The length of the film can be accurately controlled by the excellent acceleration and positioning performance of AC servo motor.

Servo motor working principle

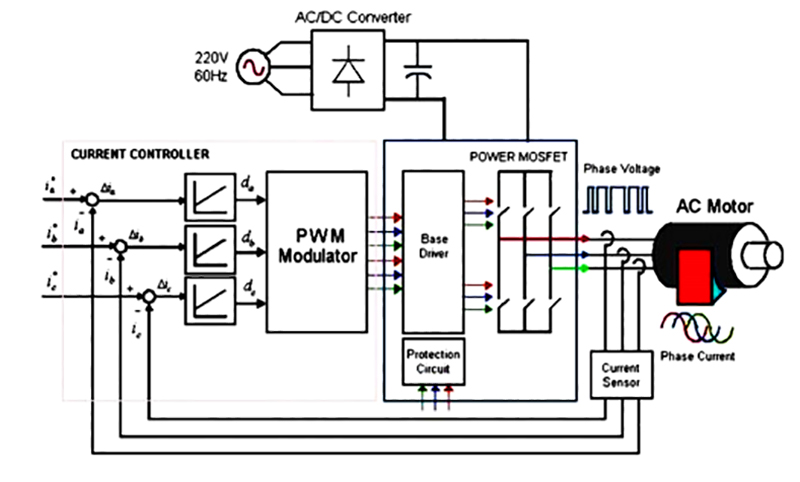

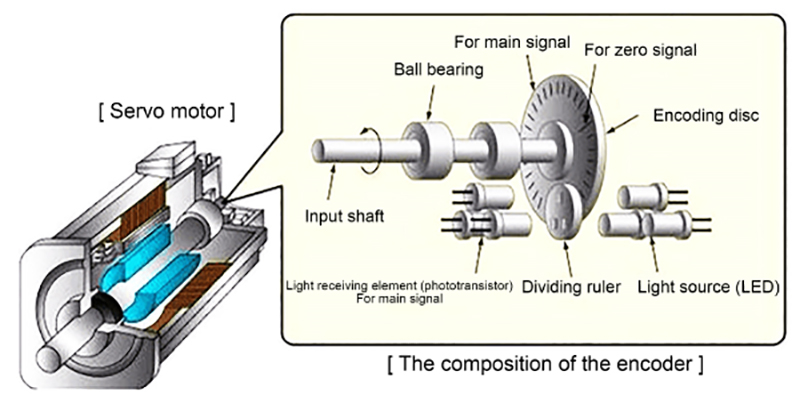

How does a sevo motor work? Servo motor mainly depends on pulse for fixing position, when it receives 1 pulse, then rotates for 1 pulse relative angle to realize displacement. Servo motor has function to send out pulse, therefore, servo motor would send out relative quantity pulse when rotating a certain angle. Then, it acts in cooperation with servo motor received pulse, or called closed loop. In the case, system knows the pulse quantity sent to servo motor, and the pulse received in return, then can control the motor operation accurately, and realize accurate position fixing, up to 0.001mm. The rotor inside servo motor is permanent magnet, U/V/W 3 phase electricity controlled by driver forms electromagnetic field, rotor rotates under action of magnetic field, simultaneously the coder inside motor gives signal back to driver, driver compares the feedback value and target value. The values are compared, and the angle of rotation of the rotor is adjusted. The accuracy of the servo motor is determined by the encoder (number of lines). The torque and speed of the controlled object are controlled by the signal voltage. When the magnitude and polarity of the signal voltage change, the speed and direction of the motor's rotation also change.

The rotor of an servo motor is usually made a different look like a squirrel cage, but in order to make the servo motor have a wider speed range, linear mechanical characteristics, no "rotation" phenomenon and fast response performance, it should have these two characteristics: the rotor resistance is large and the moment of inertia is small. At present, there are two types of rotor structures that are widely used: one is a squirrel cage rotor with a high-resistivity conductive material. In order to reduce the moment of inertia of the rotor, the rotor is made slender; another is the hollow cup-shaped rotor made of aluminum alloy. The cup wall is very thin, only 0.2-0.3mm. In order to reduce the magnetic resistance of the magnetic circuit, a fixed inner stator should be placed in the hollow cup-shaped rotor. The rotor has a small moment of inertia, quick response and stable operation, so it is widely used.

When the servo motor has no control voltage, there is only the pulsating magnetic field generated by the excitation winding in the stator, and the rotor is stationary. When there is a control voltage, a rotating magnetic field is generated in the stator, and the rotor rotates in the direction of the rotating magnetic field. When the load is constant, the speed of the motor changes with the control voltage. When the phase of the control voltage is opposite, the servo motor will be reversed.

The AC servo motor runs smoothly and has low noise. However, the control characteristics are nonlinear, and due to the large rotor resistance, large loss, and low efficiency, compared with the same capacity DC servo motor, it is large in size and heavy in weight, so it is only suitable for small power control systems of 50W-100W.