What are the Different Types of Fume Extractor?

A fume extractor, also known as an air purifier or air filtration system, is a device used to remove and filter harmful fumes, dust, and other airborne contaminants from the air in a specific area. Fume exhaust systems are commonly used in various industries, laboratories, workshops, and manufacturing facilities. These fume extractors are designed to improve indoor air quality and create a safe and healthy working environment, especially in settings where processes generate pollutants or fumes. Next, we will explore the different types of fume extractors available, each tailored to specific applications and needs.

Types of Fume Extractors

-

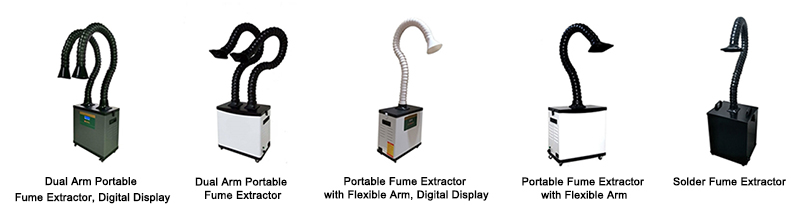

Portable Fume Extractors: Portable fume extractors are versatile units designed for localized air purification. They are equipped with flexible hoses or arms that can be positioned close to the source of fumes, such as welding stations, soldering stations, or workbenches. These extractors effectively capture pollutants at their origin, preventing them from spreading throughout the room.

-

Bench Top Fume Evacuators: These fume mitigation systems are designed to sit directly on a workbench or tabletop. They are ideal for small-scale applications where fume generation is limited to a specific area.

-

Ducted Fume Extractors: Ducted fume extractors, also known as centralized systems, are installed with a network of ducts that collect contaminated air from multiple sources and channel it to a central filtration unit. These systems are commonly used in industrial settings where pollutants are generated at various workstations across a large area. Ducted extractors offer efficient and comprehensive air purification, maintaining air quality throughout the workspace.

-

Soldering Fume Extractors: These fume hoods are specialized for capturing and removing soldering fumes generated during electronic assembly processes. Soldering fume extractor systems usually come with a suction arm or nozzle to extract fumes directly from the soldering site.

-

Wet Scrubbers: Wet scrubbers are specialized fume extractors used to remove harmful gases and particulates from industrial exhaust streams. They operate by spraying a liquid solution, often water, into the contaminated air. The solution captures pollutants, which are then collected and disposed of. Wet scrubbers are commonly employed in industries such as chemical manufacturing and metal processing.

-

Activated Carbon Filtration Fume Extractors: Fume extractors equipped with activated carbon filters are effective at removing volatile organic compounds (VOCs) and odorous substances from the air. Activated carbon has a porous structure that adsorbs gas-phase pollutants. These extractors are commonly used in laboratories, printing facilities, and painting workshops to eliminate harmful chemicals and unpleasant odors.

-

HEPA Filtration Fume Extractors: High-Efficiency Particulate Air (HEPA) filters are a common feature in many fume extractors. These filters can capture particles as small as 0.3 micrometers with high efficiency, making them ideal for removing fine dust, allergens, and other microscopic particles. HEPA-equipped fume extractors are essential in industries like woodworking, pharmaceuticals, and electronics manufacturing.

-

Welding Fume Extractors: Similar to soldering evacuators, welding fume extractor devices are designed to capture and remove fumes generated during welding operations. They help protect welders from inhaling harmful metal fumes and particles.

-

Electrostatic Dust Collectors: Electrostatic dust collectors use electrostatic charges to capture and collect particles and smoke in the air. When contaminated air passes through an electric field, particles become charged and are attracted to plates or collector plates with opposite charges. This technique is commonly used in industrial settings to capture fine particles, smoke and aerosols.

-

Combination Systems: Many advanced fume extractors combine multiple filtration methods to address a wider range of pollutants. These combination systems might incorporate HEPA filters, activated carbon filters, electrostatic precipitators, and more. By utilizing different filtration mechanisms, these extractors ensure comprehensive air purification and are suitable for complex environments with diverse pollutants.

The type of fume evacuators chosen depends on the specific application, the volume of fumes generated, and the contaminants that need to be removed. It's essential to select the right fume extractor system to ensure effective air quality control and worker safety. ATO shop provides you with a variety of functional types of fume extractor devices, you can just buy the right one according to your actual needs.