What are the Types of Water Chiller?

A water chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. Water chiller commonly known as refrigerator, ice water machine, cooling machine, etc. Because of the wide use of all walks of life, so the name is too numerous. With the continuous development of chiller industry, more and more human beings begin to pay attention to the chiller industry, and industrial water chiller is becoming more and more important to human beings.

Water chiller is mainly divided into air cooled water chiller and water cooled water chiller. In this article, we will introduce these two types of chillers in ATO online shop.

Air-cooled Water Chiller:

Industrial air cooled water chillers use the ambient air as the direct cooling medium for the refrigeration circuit, making them more practical for many facilities and processes. This means that they are usually more common in smaller to medium sized applications in locations were ambient extremes are not typical. Air cooled water chillers are advantageous in that they have simpler maintenance requirements (as they are less-complex systems than water-cooled chillers) and have lower installation costs. Air cooled chillers are typically smaller than water cooled chillers, with many medium sized systems installed outside.

The air cooled condenser will cool the water at room temperature through the compressor of the chiller to a certain temperature to strengthen the cooling mold or machine. Air cooled water chiller is used as a single machine, and the cooling device is the built-in fan. It mainly has three interconnected systems: refrigerant circulation system, water circulation system and electrical automatic control system. Industrial automation shore offers different models air cooled water chiller, such as 1 ton water chiller, 1.5 ton water chiller, 2 ton water chiller and so on.

Three Related Systems:

- Refrigerant circulation system. The liquid refrigerant in the evaporator absorbs the heat from the water and starts to evaporate. Eventually, a certain temperature difference is formed between the refrigerant and water. The liquid refrigerant also completely evaporates into a gaseous state, which is then sucked into and compressed by the compressor (pressure and temperature increase). After being throttled by the expansion valve, the refrigerant becomes low-temperature and low-pressure refrigerant and enters the evaporator to complete the refrigerant circulation process.

- Water circulation system. The water pump is responsible for pumping water from the tank to the user's cooling equipment. The chilled water takes away the heat, increases the temperature, and then returns to the chilled tank.

- Electric automatic control system. It includes power supply part and automatic control part. The power supply part supplies power to compressors, fans and water pumps through contactors. The automatic control part includes temperature controller, pressure protection, delay device, relay, overload protection and other combinations to achieve automatic start and stop of water temperature, protection and other functions.

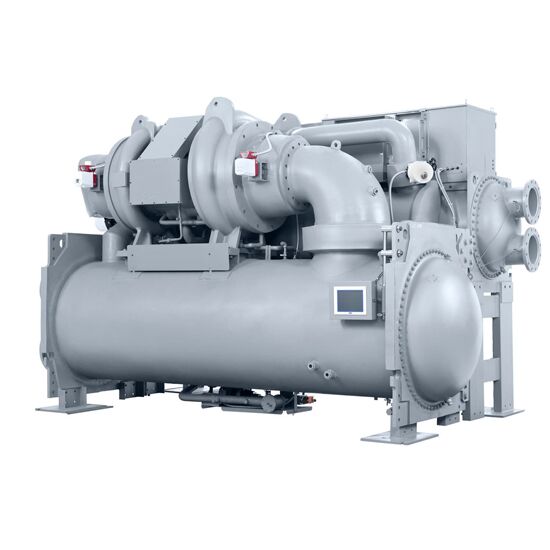

Water-cooled Water Chiller:

Water cooled water chiller is a kind of equipment for a variety of different processes of the industry, the equipment through the form of cooling to achieve the purpose of a kind of equipment. It is widely used in medical, food, biology, chemical, laser, metallurgy, machinery and equipment, electroplating, processing and other industries. Because the source of heat transfer is water, it is equipped with a special cooling tower, so it is called "water cooling".

Features of Water-cooled Water Chiller:

- All pipes are designed for thermal insulation to prevent local convection in the body pipes.

- Cooling temperature range: 5 ℃-35 ℃.

- Independent temperature controller is protected against freezing.

- Stainless steel thermal insulation water tank.

- Phase sequence protection of control line, high and low voltage switch control of refrigerant system.

- Compressor and pump have overload protection.

- The shell and tube evaporator with large capacity is adopted to make the cooling effect of the industrial water cooled chiller good, and it can be applied to the environment with high temperature.