What Causes Load Cell Drift?

What is load cell drift?

Load cell drift refers to the gradual change in the electrical output of a load cell over time, which can lead to inaccuracies in measurements. Load cells are devices that are used to measure the force or weight of an object, and they typically rely on strain gauges that are bonded to a metal structure.

Over time, load cells can experience changes in the strain gauge properties due to various environmental factors such as temperature changes, humidity, and vibration. These changes can cause the electrical output of the load cell to drift, resulting in inaccurate readings.

Load cell drift can be corrected through regular calibration and maintenance, including re-zeroing the load cell and adjusting the amplification circuitry. It is important to monitor load cell drift to ensure accurate and reliable measurements.

What causes load cell drift?

Load cell drift can prove to be a potential setback for measuring. Drift can cause your load cell to not return to 0 in between weighing results. That is a concern because the 0 baseline allows you to get accurate measurements each time. Next, the ATO will discuss several common causes of load cell drift.

Damaged load cell

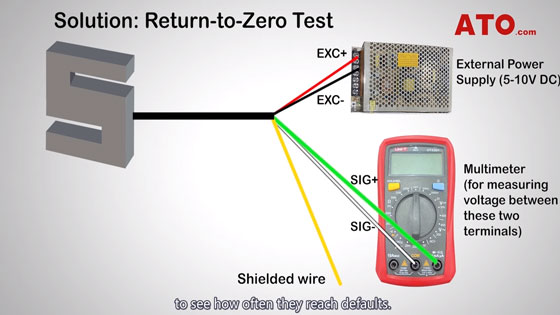

Damage to the load cell itself can cause drift. This can come from excessive strain, poor handling, or parts wearing out over time. The simple solution is to check your load cells with a Return-to-Zero test, to see how often they reach defaults. Another is to conduct routine inspections and identify parts that need to be replaced.

Dramatic temperature fluctuations

One of the most common explanations for the drift is rapid changes in temperature. Mass increases and decreases based on the heat or coolness in a room, on a micron level.

A sudden drop in temperature causes the item’s mass to decrease, and it takes a while to return to its original reading. This influx of heat often causes Load Cell drift and must be taken into consideration.

A solution for extreme temperatures is to recalibrate on a regular basis if you cannot change the warehouse's environmental conditions. We recommend that in areas with different seasons, you should schedule regular load cell recalibrations.

Moisture damage

Moisture is another cause for the potential drift and many warehouses and outdoor areas run the risk of exposing a weighing system to excess droplets and vapor. The droplets can get into the cables, damaging them and the instruments inside the load cell. They can cause clogs and rust, which are not welcome.

Check your Load Cell Junction Box and the cables for moisture when doing checks. Create waterproof environments for your load cells if possible, and do what you can to remove potential humidity.

Lack of moisture

As well as excessive moisture is a problem, it can introduce static electricity into your scales, which is likely to cause load cells to drift. Load cells are susceptible to this build-up, especially if they are not properly earthed.

When the static discharge becomes too high, it can skew the load cell's readings. Have a setting to remove the static electricity when it reaches a threshold value. One option is to add ionizers to your working environment to reduce the amount of positive and negative ions in the air.

The following video introduces the causes and solutions of load cell drift, if you want to see more videos, please follow ATO Youtube.