What is a Air Filter?

Air filters are one of the essential equipment in industrial production. These filters can filter out harmful substances such as dust, pollutants, bacteria, and viruses in the air, making the production environment cleaner and healthier, while also protecting production equipment from the impact of pollution. The working principle of industrial air filters is to filter out harmful substances in the air through filtering media, thereby purifying the air. In this article, ATO industrial automation will briefly introduce air filter to you, including its main performance indicators, function, working principle and its application etc., to help you have a better understanding of it.

Main Performance Indicators of Air Filter

Filtering accuracy:

Refers to the maximum diameter of impurity particles allowed to pass through. The key to affecting filtration accuracy is the filter element, which can be selected according to the needs of subsequent components to achieve the corresponding filtration accuracy.

Flow characteristics:

It refers to the relationship curve between the air flow rate through the filter and the pressure drop at both ends of the filter under a certain inlet pressure. In practical use, it is best to choose within the range of pressure loss less than 0.03MPa. In air filters, the main factors that affect the flow characteristics are the body and filter element.

Water separation efficiency:

The water separation efficiency refers to the ratio of the separated water to the water content in the air at the inlet. It is generally required that the water separation efficiency of the air filter be not less than 80%, and the main factor affecting the water separation efficiency is the deflector.

Function of Air Filter

The compressed air from the air source contains excessive water vapor and oil droplets, as well as solid impurities such as rust, sand particles, pipeline sealant, etc. These can damage the piston sealing ring, block small exhaust holes on the components, shorten the service life of the components or make them ineffective. The function of an air filter is to separate liquid water and liquid oil droplets from compressed air, and filter out dust and solid impurities in the air, but it cannot remove gaseous water and oil.

Working Principle of Air Filter

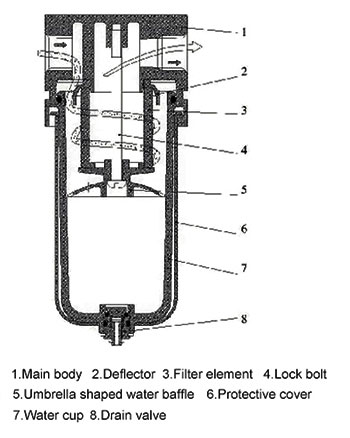

The working principle of the air filter is shown in the figure.

The compressed air flowing in from the inlet is introduced into the guide plate (2), which has evenly distributed diagonal teeth similar to fan blades, forcing the high-speed flowing compressed air to rotate strongly along the tangent direction of the teeth. The liquid water, oil, and large impurities mixed in the air are separated under strong centrifugal force, thrown onto the inner wall of the water cup (7), and flow to the bottom of the water cup. Compressed air that removes liquid water, oil, and large impurities is further filtered through the filter element (3) to remove small solid particles, and then clean compressed air is output from the outlet. The umbrella shaped water baffle (5) separates the water cup into two parts, the upper and lower parts, and the lower part maintains a pressure static zone, which can prevent the high-speed rotating airflow from sucking up the water and oil at the bottom of the cup. The water and oil gathered at the bottom of the cup are discharged from the drain valve (8). The air filter must be installed vertically with the water cup facing downwards.

Application of Air Filter

The biggest application of air filtration is in residential buildings, followed by commercial and industrial buildings. In addition, filtration equipment is commonly used in the following situations: clean rooms; Copy equipment; Indoor air purifier; Anesthetic gas passing equipment; Application of laser surgery; HVAC system (heating, ventilation, and air conditioning systems); Constant temperature chamber; Computer printer studio air filtration system; Air conditioners, etc.

- Residential market

Due to the continuous improvement of people's requirements for quality of life, the original air filtration system in residential buildings can no longer meet people's needs, and higher performance electrostatic filters have become the preferred alternative to the original air filters. However, compared to ordinary glass fiber filters, the application of electrostatic filters is also limited due to the high cost of filtering media. - Office Building Applications

Computer terminals are a source of ozone and volatile organic compounds. Ink jet printers are a source of hydrocarbons and ozone. Dry process photo copying machines produce hydrocarbons, inhalable suspended particles, and ozone; Fax machines generate ozone and volatile organic compounds; Laser printers produce hydrocarbons, ozone, and inhalable particles, among others. These products have seriously polluted the indoor environment and caused certain harm to people and office equipment.

- Production factories

The requirements for air quality vary greatly among different factories. Factories equipped with smoke exhaust hoods and pollution control equipment need to replenish a large amount of air. If the ambient air in the area where these factories are located is polluted, the supplemented air must be filtered before being distributed to the workplace. In semiconductor production and pharmaceutical industry, there is a high requirement for air cleanliness. - Hospitals

The health industry is a very large and special industry, and it also has high requirements for air cleanliness. Usually, the minimum requirement for hospital air is to use a combination of a 30% efficiency pre-filter and a 90% efficiency final filter for filtration. - Food Industry

The food industry is becoming an expanding market for air filtration equipment. To maintain the fresh taste of food, the use of disinfection to eliminate pollution has gradually become obsolete. This makes eliminating air pollution related to products even more important.

In summary, air filters play a crucial role in industrial production. They can purify the air, protect production equipment and workers' health, improve production efficiency and product quality. When selecting filters, the appropriate filter should be selected based on the production environment and filtration requirements.