What is a Knife Switch?

Knife switch is a common electrical control device widely used in various circuits. In this article, ATO industrial automation will comprehensively, elaborately, completely, and deeply discuss knife switches from three aspects: structure, working principle, and applications.

Structures of Knife Switch

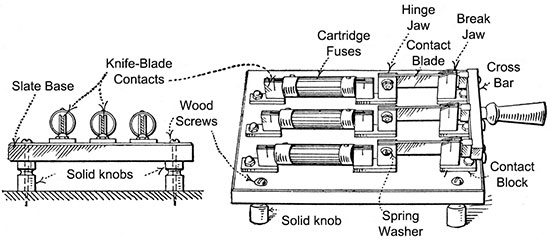

A knife switch typically consists of the following main parts:

- Blade:

The blade is the core component of the knife switch, often made of conductive materials such as copper or aluminum. The blade has a flat shape, with one end fixed in the switch housing and the other end movable through manual operation. - Fixed Contacts and Moving Contacts:

The knife switch also includes fixed contacts and moving contacts. Fixed contacts, made of metal, are fixed in the switch housing and form an electrical connection with the blade's contact surface. Moving contacts, also made of metal, form an electrical connection with the blade's contact surface and achieve the closing and opening of contacts through the movement of the blade. - Operating Lever:

The operating lever is the part used for manual operation of the knife switch, usually made of insulating materials to prevent electrical leakage or the risk of electric shock. The operating lever is connected to the blade, and pushing or pulling the lever causes the blade to move, controlling the contact state of fixed and moving contacts. - Housing:

The housing is the external protective shell of the knife switch, used to fix and protect internal components such as the blade, contacts, and operating lever. The housing is typically made of insulating materials to prevent electrical leakage or the risk of electric shock.

Working Principles of Knife Switch

The working principle of a knife switch can be described simply: by manually operating the operating lever, the blade moves within the housing, controlling the closing and opening of contacts.

Specifically, the working process of a knife switch includes the following steps:

- Initial State:

In the initial state, the blade is in a fixed position within the switch, and the contacts are open. The position of the blade is controlled by the operating lever, allowing users to choose the switch position as needed. - Manual Operation of the Blade:

Users manually operate the operating lever to move the blade from the initial position to the target position. The movement of the blade causes the contacts to make or break. - Closing of Contacts:

When the blade reaches a certain position, direct contact is made between the fixed contacts and moving contacts, closing the contacts. The closure of contacts allows current to flow through the circuit. - Opening of Contacts:

As the blade continues to move, the contact between fixed contacts and moving contacts is broken, opening the contacts. The opening of contacts interrupts the current flow in the circuit. - Completion of Operation:

Once users complete the operation of the blade, the knife switch finishes its work. The closing and opening of contacts are controlled by the movement of the blade, allowing users to open or close the circuit as needed.

Applications of Knife Switch

Knife switches are widely used in various low-voltage circuits, primarily for controlling the opening and closing of circuits. Common applications of knife switches include:

- Home Circuit Control:

In home circuits, knife switches are commonly used to control the power supply to lighting fixtures, outlets, and other devices. Users can use knife switches to open or close circuits, facilitating control of electrical devices. - Industrial Automation Control:

In the field of industrial automation, knife switches are widely used to control circuitry in equipment. Knife switches can enable remote control and automated operations, improving production efficiency and safety. - Distribution Systems:

In distribution systems, knife switches are used to control the on-off status of power sources, allowing for the distribution and regulation of electricity. Knife switches can respond quickly and withstand high currents and voltages, ensuring the safe and stable operation of power systems. - Power Transmission and Substations:

In power transmission and substations, knife switches are used to control the opening and closing of circuits. Knife switches facilitate the switching and maintenance of power systems, ensuring the reliability and stability of power supply.

In conclusion, a knife switch is a common electrical control device with a structure comprising a blade, fixed contacts, moving contacts, an operating lever, and a housing. The working principle involves manual operation of the blade to control the closing and opening of contacts. Knife switches are widely used in home circuit control, industrial automation control, distribution systems, and power transmission and substations. They play a crucial role in circuit control and power system maintenance.

This comprehensive, detailed, complete, and in-depth discussion aims to assist readers in understanding knife switches and gaining a deeper insight into their applications and significance. We hope this article proves helpful in enhancing readers' understanding of knife switches.