What is Mud Pump used for?

As the name suggests, the mud pump is a device used to transport mud-like liquids with high consistency or more particles. The pump is an important part of mechanical equipment and a machine that converts mechanical energy into liquid pressure energy. Now it has been widely used in drilling, construction sites, enterprise production, mud pond pumping, etc. And now it is used in daily production. Only being familiar with the working principle of the pump can help the operator to use the pump more skillfully and make it play an effective role in industrial production. The following is a detailed description of the working principle and application of the mud pump.

Types

At present, screw pumps and sewage pumps with excellent medium adaptability are mainly used as mud pumps in the  market. Screw pumps can handle a variety of high-viscosity slurry liquids, and are mainly used in industries and construction sites, while sewage pumps have higher processing efficiency and can also be used for diving operations, and are mainly used for mud pond suction, fish pond oxygenation, etc.

market. Screw pumps can handle a variety of high-viscosity slurry liquids, and are mainly used in industries and construction sites, while sewage pumps have higher processing efficiency and can also be used for diving operations, and are mainly used for mud pond suction, fish pond oxygenation, etc.

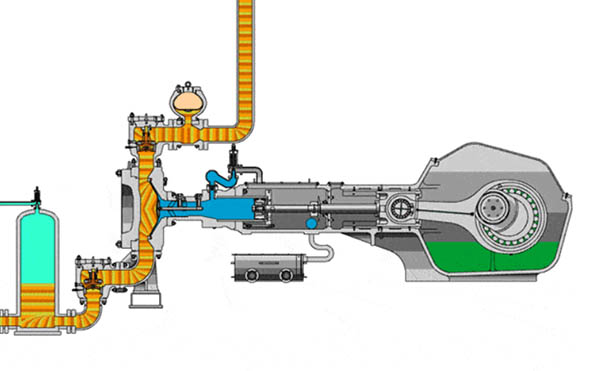

Commonly used mud pumps are piston or plunger type. The crankshaft of the pump is driven by the power machine to rotate, and the crankshaft drives the piston or plunger to reciprocate in the pump cylinder through the crosshead. Under the alternate action of suction and discharge valves, the purpose of pressure feeding and circulating flushing fluid is realized.

According to the function, the mud pump can also be divided into two types: single-acting and double-acting. The single-acting type only completes one suction and drainage action in one cycle of the reciprocating motion of the piston. The double-acting mud pump completes two suction and drainage actions every time it reciprocates. If classified according to the number of cylinders of the pump, there are three types: single cylinder, double cylinder and triple cylinder.

Working principle

Its working principle is to rely on the reciprocating motion of the piston to make the working volume of the pump chamber change periodically, and then suck in and discharge liquid. It is composed of pump cylinder, piston, water inlet and outlet valves, water inlet and outlet pipes, connecting rod and transmission device, and is more suitable for drilling operations with high pressure and small flow.

The plunger pump is one of the important devices of the hydraulic system. The pressure of the pump depends on the depth of the borehole, the resistance of the channel through which the flushing fluid passes, and the nature of the flushing fluid delivered. The deeper the hole, the greater the resistance of the pipeline and the higher the pressure required. As the diameter and depth of the borehole change, the displacement of the pump is required to be adjusted at any time.

A gearbox is installed in the pump mechanism or its speed is adjusted by a hydraulic motor to achieve the purpose of changing the displacement. In order to accurately grasp the change of the pressure and displacement of the pump, a flow meter and a pressure gauge should be installed on the mud pump to let the drilling personnel understand the operation of the pump at any time, and at the same time judge whether the condition in the hole is normal through the pressure change to prevent accidents in the hole.

The two main parameters of mud pump performance are displacement and pressure. Displacement is calculated by several liters per minute, which is related to the diameter of the borehole and the return speed of the required flushing fluid and the bottom of the hole, that is to say, the larger the diameter of the hole, the greater the required displacement. The upward return speed of the flushing fluid is required to be able to flush the rock cuttings and rock dust cut off by the drill bit away from the bottom of the hole in time and reliably carry them to the surface. During geological core drilling, the upward and downward speed is generally about 0.4 to 1.0 m/min.

Clean drilling

A mud pump is a machine that delivers flushing fluid such as mud or water to the borehole during oil drilling. It is an important part of drilling equipment. In the process of oil drilling, the mud pump injects mud into the downhole with the drilling of the drill bit. During this process, the mud pump can cool the drill bit, clean the drilling tool, and some wastes such as cuttings are brought back to the ground to clean the well.

In the commonly used positive circulation drilling, the surface flushing medium, clear water, mud or polymer flushing fluid, is passed through the high-pressure hose, faucet and the center hole of the drill string to the bottom of the drill bit under a certain pressure to cool the drill bit to achieve the purpose of removing and transporting the cuttings to the surface.

Clear debris

During the drilling process, the drill bit continuously breaks the rock at the bottom of the hole to generate cuttings and circulate the mud flushing fluid, transport the debris to the ground and keep the bottom of the hole clean, which is beneficial for the drill bit to continue to break the rock. In addition to this, mud pumps also provide energy for drilling tools, delivering energy to power augers, hydraulic hammers and other hydraulic percussion drilling tools.

Transport of special substances

In some special work, such as plugging and sealing holes, the mud pump can be used to pour special substances one by one into the grout or other blocking substances in the holes. Oil drilling generally adopts positive circulation drilling. Under a certain pressure, the mud pump passes through water, high-pressure hose and the center hole of the drill string, and the clean water, mud or polymer is transported to the bottom of the well.

Slurry pumps are used to transport abrasive slurry containing solid particles in mining, metallurgy, coal and other industries. It is a coaxial pump with a water pump and a motor. During operation, the motor shaft drives the impeller of the pump to rotate, and transmits energy to the slurry medium to generate a certain flow, drive the solid flow, and realize slurry transportation.

Correct maintenance of mud pump

The mud pump is an important process equipment for drilling operations. Whether the drilling project can be completed safely, on time and efficiently, its regular maintenance and maintenance cannot be underestimated. Correct and timely maintenance of the drilling pump is a necessary measure to ensure the normal operation of the mud pump and prolong its service life. Any pump use should pay attention to this link.

When the oil level is stable, check the oil level at the power supply at least once a day. If using a chain drive, check the oil level in the chain case. Observe the working condition of cylinder liner and piston. It is normal for a small amount of mud to flow from the piston pull rope.

Check the cylinder bore of the frame. If there is a large buildup of mud and oil, it should be cleaned up. Check the water tank of the spray pump. If the water is insufficient, it should be replenished. If the water quality is polluted, it should be replaced and the water tank should be cleaned at the same time.

Check whether the inflation pressure of the air chamber meets the requirements of the operating conditions. The safety valve should be checked frequently and replaced in time. Loosen the piston rod clamp every day, and check whether the connecting surface of the clamp cone, piston rod and intermediate tie rod is clean.

Check the valve cover seal and cylinder liner seal (including the seal between the wear plate and the liquid cylinder) alarm holes frequently. If the mud is discharged, replace the corresponding sealing ring in time.