What is the Strain Gauge Used for?

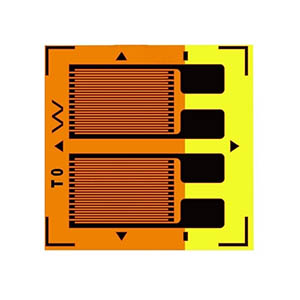

Strain gauges are used in a wide range of applications to measure physical quantities such as strain, stress, bending moment, torque, acceleration, and displacement. They can measure physical quantities such as strain, stress, bending moment, torque, acceleration, and displacement. The applications of strain gauges can be divided into two main categories: the first is the application of strain gauges to certain elastomers and their connection to measurement circuits. In the first category, strain gauges are attached to certain elastomers and connected to a measurement circuit, thus forming a special strain gauge for measuring various physical quantities. In a strain gauge sensor, the sensitive element is generally a variety of elastomers, the sensing element is the strain gauge and the measurement conversion circuit is generally a bridge. The conversion circuit - generally a bridge circuit - is used. The second type of strain gauge is a strain gauge that is attached to the test piece and then connected to a strain gauge. The strain gauges are then connected to the strain gauge and the strain variation is read directly from the gauge.

Application of resistance-strain testing technology in civil engineering

As a non-destructive testing technology, strain gauge electrical measurement has been widely used in various engineering structures. However, the test results of resistance strain gauges are greatly affected by environmental factors such as temperature, humidity, and wire length. How to deal with these problems is the key to the application of resistance strain gauges in civil engineering.

The use of resistance strain gauges in strain gauge electrical measurement can be divided into two methods. One is to directly paste the strain gauges on the surface of a loaded part for measurement. This method is simple, but not precise enough.

Another method is to paste the strain gauge on the elastic element to make a sensor, establish the functional relationship between the load and the resistance change after being loaded, and obtain the measured load value through the predetermined load calibration curve. The obtained measurement results are relatively accurate.

Application of load determination

Various structures are subjected to various external forces during their operation, and these external forces are called loads in engineering. Load is the main basis for strength and stiffness calculations. There are usually three ways to determine the load at design time. That is analogy, calculation, and actual measurement. The following introduces the resistance strain method in the actual measurement method to measure the load.

The method of determining the load by the resistance strain method is to measure the load value by using a measurement system composed of strain gauges, strain gauges, and indicating recorders. First, the strain gauge is pasted on the part or sensor, and the resistance in the strain gauge changes after the part is loaded and deformed. The change of the resistance value is converted into a voltage signal and amplified by the measuring bridge composed of the strain gauge, and finally, the indicator or recorder shows a curve that changes proportionally to the load, and the required data value can be obtained through calibration.

This method has been widely used in the load determination of various structures, such as ship locks, bridges, and building construction, and other engineering fields.

Intelligent health monitoring applications

Large and important civil engineering structures, such as bridges, super high-rise buildings, TV towers, dams, nuclear power plants, offshore oil production platforms, etc., have a service life of decades or even hundreds of years. Under the influence, the accumulation of damage and even sudden accidents will inevitably occur. Although there were signs of loopholes, subsidence, and cracks before some accidents, accidents could not be avoided due to the lack of an alarm monitoring system. Therefore, it has become necessary to conduct health inspections on existing important structures and facilities, evaluate their safety status, repair, and control damage, and add long-term health inspection systems to new structures and facilities.

At present, the strain monitoring of reinforced concrete structures generally uses resistance strain gauges, which are pasted on the surface of the structure and then embedded in the concrete to perform real-time/online intelligent health monitoring of reinforced concrete structures.