Wiring RS485 Port of Torque Sensor for Modbus Communication

ATO digital rotary torque sensor with LCD display has the capacity range from 0.1 Nm/0.3 Nm/1 Nm/5 Nm/10 Nm/300 Nm/1000 Nm to 10000 Nm. LCD display can show torque, speed and power value at the same time. This article shows you how to wire and set a torque sensor in Modbus mode via S484 interface as a walkthrough of one of the applications of ATO torque sensors.

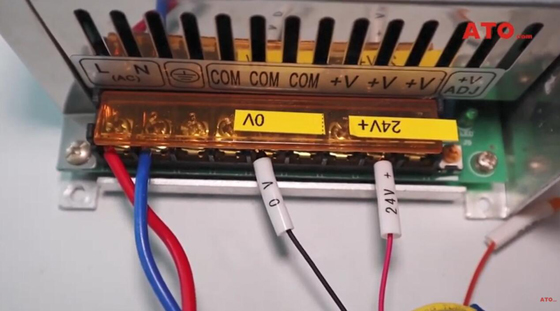

ATO torque sensor can communicate through RS485 interface. Wire the dedicated cable to the sensor and find out leads marked 24V+, 0V, RS485A, RS485B. Connect the leads 24V+ and 0V to the power supply. Connect RS485A and RS485B to T/R+ and T/R- of the USB converter.

The torque sensor has the function of automatic zero clearing when powered up. Long press K1, and then short press K1 to switch parameter lists to check the sensor’s baud rate, station number, communication format and other items.

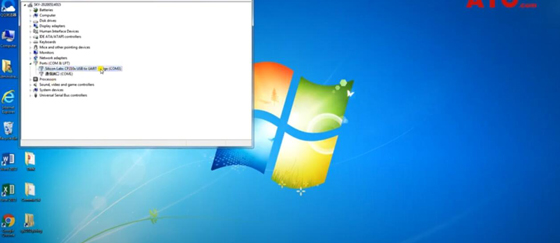

Connect the RS485 to USB converter to the computer and check whether the converter driver has been detected. It can be seen that the driver was detected on the COM3 port. If the converter was not detected, it’s needed to install the driver.

- Run the Commix test software.

- Select COM3 in the Port drop-down list.

- Select 38400 for baud rate as shown on the sensor screen before.

- Select CRC16 Modbus RTU for Communication protocol.。

- Read the serial port.

- Read the current torque data (01 03 00 00 00 02) into the program.

- The torque data storage address is 00 00H.

- The result is shown like this (01 03 04 00 00 00 00 FA 33).

- The high and low bits are 00H 00H (the decimal number is0.000Nm).

- Read the communication rate address 14H.

- The result is 00 04H (it means 4 in the decimal system).

- This is our protocol content: 1=9600, 2=14400, 3=19200, 4=38400, 5=57600, 6=115200.

- You can find the communication rate of the sensor shown on the panel also being 4 (38400).

- Change the address to 00 02H, and send a command to read the current speed value.

- The result is 00 5D in hex format (it is 93rpm in decimal).

- 00 5C refers to 92rpm in decimal, 00 73 refers to 115rpm in decimal.

- Then change the address to 00 00 to read the real-time torque.

- 00 18 in hexadecimal is represented in decimal as 0.018Nm.

- 00 31 (0.049Nm in decimal)

- 00 47 (0.071Nm in decimal)

- 00 2F (0.047Nm in decimal)

- 00 26 (0.038Nm in decimal)

For more details about torque sensor Modbus communication via RS485 interface, please view the video below.