Advantages and Disadvantages of Air Pressure Booster

Fri, Jun 04 by ATO.com

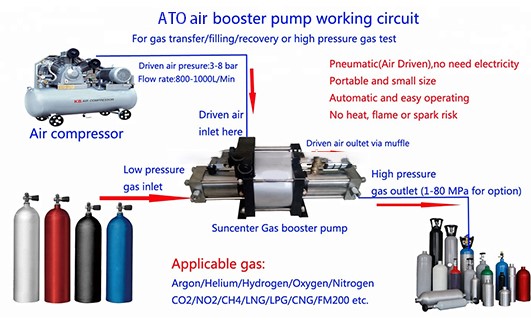

The principle of air booster pump is to produce high hydraulic pressure of small area piston by using low pressure of large area piston. The air booster pump is used in the working environment where the original air pressure system needs to increase the pressure. It can increase the air pressure of the working system to 2-5 times, only the compressed air in the working system can be used as the air source. The pump is suitable for single air source pressurization. ATO provides professional high-quality gas booster pumps as follows, which will describe their advantages and disadvantages.

Advantages of Air Pressure Booster

- Energy saving is remarkable: the biggest feature of ATO air pressurizer is energy saving. Compared with the air pressure booster, the air booster pump only needs to provide driving air source, and does not need to consume electricity to help the user plant save costs. At the same time, when the air booster pump reaches the predetermined pressure, it will stop working automatically, and the consumption will be zero.

- Stable air pressure: because the pneumatic air booster pump adopts single air control non-equilibrium gas distribution valve to realize the reciprocating movement of the pump, it can start slowly, and can adjust the response quickly in the case of large fluctuation of gas consumption. This is our company pneumatic booster pump non-polar regulation of high-quality performance.

- Low operating noise: compared with ordinary high-pressure compressed air compressor, air pressurizer has small vibration and low noise, and is suitable for more occasions.

- Price: compared with the expensive high-pressure compressed air compressor before, pneumatic air booster pump can be said to help customers reduce more than half of the cost.

- Can achieve constant pressure air supply: pneumatic air booster pump can work in a wide range of exhaust volume. According to the actual gas consumption, the real-time automatic adjustment, control the exhaust gas. How much gas is used to produce, and when the gas consumption is low, it can also make the air booster pump sleep automatically, greatly reducing the energy loss.

- Maintenance is simple and maintenance cost is low: in most cases if the air-driven air booster pump can not work normally, it is basically a problem with the sealing ring. As long as the new sealing ring is replaced, it can work normally. Even the international high sealing ring, compared with a pneumatic booster pump, the price is very low.

- Flexible application: air pressurizer has various models, which can be selected according to the proportion and flow of pressurization required by customers. At this point, saisent will try to help the customer.

- Volume and weight: light weight, small volume, easy to carry

Wow, there are so many advantages of the air booster pump. But it is not to be ignored that the air booster pump has some disadvantages. Let's look at the following:

Disadvantages of Air Pressure Booster

- Flow: the air booster pump may provide relatively low flow compared to the electric booster pump. When the customer factory actually needs a large air supply flow and the actual situation of the factory does not support multiple parallel pneumatic booster pumps to build a parallel pneumatic booster system, the intention of both parties cannot be reached.

- Need to drive air source: what does the pneumatic air booster pump mean? That is to say, it is driven by gas, that is to say, it needs a certain air source to work, which may not be available for some customers.

- Gas consumption: the gas consumption is mainly determined by the reciprocating times per minute of the piston of the driving cylinder of the booster pump. In case of inconvenient supply pressure, the reciprocating times of the pump depend on the large or small discharge gas pressure. The cessant booster pump does not work properly when the air supply provided by the customer's factory is not enough to drive the air-driven air booster pump.

- The common problem of pneumatic booster pump: air pressure booster is a device for pressurization and pressure regulation of "air" medium, and mixing of other gases is not recommended. If other gases need to be pressurized and stabilized, it is recommended to purchase another gas booster pump such as nitrogen booster pump, hydrogen booster pump, oxygen booster pump, etc, otherwise, the purity of gas may be affected.