Centrifuge Machine Basics

A centrifuge is a machine that uses centrifugal force to separate the components of liquid and solid particles or liquid-liquid mixtures. Centrifuges are mainly used to separate solid particles in suspension from liquids, or separate two liquids of different densities and immiscible in the emulsion (e.g. separating cream from milk); They can also be used to exclude liquids from wet solids, such as shaking dry wet clothes with a washing machine; Special ultra-speed tubular separators can also separate gas mixtures of different densities; Taking advantage of the different sedimentation speeds of solid particles of different densities or particle sizes in the liquid, some sedimentation centrifuges can also classify solid particles according to density or particle size.

Introduction to the centrifuge machine

A centrifuge machine is a device that uses centrifugal force to subject a specimen to a specified constant force, for example, to separate various components of a fluid. This is achieved by spinning the fluid at high speed within a container, thereby separating fluids of different densities (e.g. cream from milk) or liquids from solids. It works by causing denser substances and particles to move outward in the radial direction. At the same time, objects that are less dense are displaced and moved to the center. In a laboratory centrifuge that uses sample tubes, the radial acceleration causes denser particles to settle to the bottom of the tube, while low-density substances rise to the top. A centrifuge can be a very effective filter that separates contaminants from the main body of fluid.

Industrial-scale centrifuges are commonly used in manufacturing and waste processing to sediment suspended solids or to separate immiscible liquids. An example is the cream separator found in dairies. Very high-speed centrifuges and ultracentrifuges able to provide very high accelerations can separate fine particles down to the nano-scale, and molecules of different masses. Large centrifuges are used to simulate high gravity or acceleration environments (for example, high-G training for test pilots). Medium-sized centrifuges are used in washing machines and at some swimming pools to draw water out of fabrics. Gas centrifuges are used for isotope separation, such as to enrich nuclear fuel for fissile isotopes.

History of centrifuge machine

The development of centrifuges has been nearly two hundred years. The first centrifuge was invented in Germany in 1836, while the earliest use of centrifugal force was in ancient China, where people often tied a rope to a pottery jar, vigorously swung it around, and separated honey from honeycombs through the centrifugal force, which was affected by gravity. This was the earliest application of centrifugal force.

With the invention of the first centrifuge in Germany, decades later, the first cream separator centrifuge that could separate cream from milk was invented in Sweden. This was the first time a centrifuge was applied in the food industry.

Later, two scientists in Sweden developed a faster and higher speed centrifuge based on the original one. By then, centrifuges could be used in industrial production.

In 1950, centrifuges in Switzerland once again received a performance boost. By this time, centrifuges could be directly driven by variable frequency motors. The above developments laid the foundation for centrifuges in scientific research, hospitals, industrial production, and other fields.

Since then, the development of centrifuges has been rapid. Today, there are countless types of centrifuges. Such as high-speed centrifuges, low-speed centrifuges, high-speed refrigerated centrifuges, low-speed refrigerated centrifuges, floor-standing low-speed centrifuges, floor-standing high-speed centrifuges, floor-standing high-speed refrigerated centrifuges, floor-standing low-speed refrigerated centrifuges, benchtop low-speed centrifuges, benchtop high-speed centrifuges, benchtop low-speed refrigerated centrifuges, benchtop high-speed refrigerated centrifuges, mini handheld centrifuges, oil centrifuges, cream separators, dental centrifuges, and PCR laboratory centrifuges, and so on.

The centrifuge is a device that has a high-speed rotating cylinder, called a drum, which rotates around its own axis. It is usually driven by an electric motor. When a suspension (or a turbid liquid) is added to the drum, it is rapidly driven to rotate at the same speed as the drum. Under the action of centrifugal force, the various components are separated and discharged separately. Generally, the higher the speed of the drum, the better the separation effect.

Centrifuges are widely used in hospital laboratories and are essential tools for separating serum, precipitating formed cells, concentrating bacteria, PCR experiments, and more.

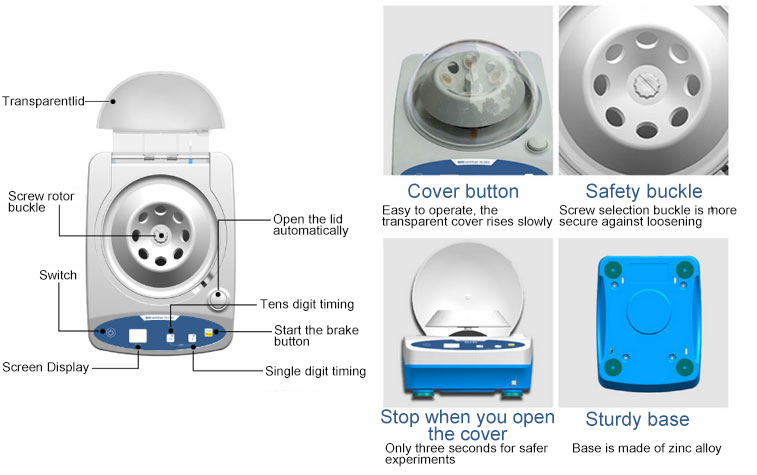

Composition of the centrifuge

The centrifuge is mainly composed of eight major parts: hydraulic system (including oil pump motor, oil cooler, relief valve, regulating valve, pressure gauge, thermometer, piston, guide rod, guide plunger, oil cylinder, oil pipeline, and oil tank), casing part (including aggregate tank, observation hole, front and rear covers), piping system (including inlet pipeline, flushing water pipeline, exhaust pipeline, and maintenance flushing water pipeline), spindle mechanism (including a scraper, hollow shaft, secondary drum, bearings, and related components), material pushing mechanism (including pushing shaft, stage drum, material pushing plate, sealing ring, bearings, and related components), driving device (including main motor, driving wheel, driven wheel, and transmission belt), base, and other accessories (including discharge port, protective cover, etc.).

Working principle of centrifuge machine

During high-speed rotation, a centrifuge causes solid substances suspended in a liquid to form sedimentation due to centrifugal force. The larger objects in terms of mass or volume in the suspension move towards the direction of the maximum radius of the rotor, while the smaller objects settle closer to the rotor radius.

As mentioned above, the centrifuge generates centrifugal force, which is related to the radius of the rotor, the speed of rotation, and the sample mass. That is, F=Rmω2 (where F is the centrifugal force, R is the radius, m is the sample mass, and ω is the rotation speed). Centrifugal force is one of the most important parameters of a centrifuge and a distinguishing factor between different grades of centrifuges. The maximum centrifugal force of a centrifuge is provided by the manufacturer upon production.

As is well-known, the radius of the rotor and the sample mass remain constant during operation, and only the rotation speed can be controlled, which is why the speed is often used to describe a centrifuge, such as high-speed centrifuge and ultra-high-speed centrifuge.

Applications of centrifuge machine

1. high-speed centrifuge machine

Currently, the high-speed medical centrifuge is mostly used as a zone centrifuge, which separates and collects cells, viruses, and DNA molecules based on the density and gradient of the sample solution. Both sample loading and unloading are done in a continuous manner. Besides being widely used in production processes, they are now also extensively used as laboratory equipment. They usually use DC frequency conversion motors or DC brushless motors that are adjustable in speed and can achieve high speeds. To reduce the weight of the machine body and drum, the shell is generally made of plastic or other non-reactive alloy materials, while the interior is typically made of lightweight alloys or other non-reactive materials.

With the rapid development of biomedical research in recent years, high-speed medical centrifuges have made significant progress and have established a separate market from low-speed centrifuges. It is expected that their growth momentum will continue to be strong, attracting more research institutions to enter. Meanwhile, high-speed medical centrifuges are the fastest-developing products in the centrifuge industry.

Centrifuges have a wide range of applications in the medical industry, including blood separation, virus research, DNA research, drug purification, and more. High-speed medical centrifuges are necessary for the separation and research of cells and DNA molecules at the microscopic level. These types of centrifuges usually have speeds above 5000 rpm but below 60,000 rpm and can provide centrifugal forces that are thousands of times greater than gravity to separate small molecules. ATO's 6000 rmp digital lab centrifuge machine with LCD display, relative centrifugal force 2100xg. Elegant appearance, compact and portable, and versatile, can meet the needs of different experiments. Blood separation usually only requires centrifuges with speeds of around 3000 rpm, and most manufacturers can produce them with good results. On the other hand, centrifuges used for drug purification in refining processes are typically low-speed centrifuges with speeds below 3000 rpm, capable of handling large volumes. To meet the GMP standards and requirements for drug production, they are usually made of flat stainless steel materials.

2. low-speed centrifuge machine

In addition to traditional industries such as textiles, chemicals, and environmental protection, centrifuges are now widely used in pharmaceutical companies to achieve the separation of mother liquor. Due to the strict regulations in the pharmaceutical industry, pharmaceutical centrifuges are typical of the flat-closed type, with stainless steel used for the parts in contact with materials or for the entire machine, in order to reduce possible contamination or damage and to improve hygiene. These types of centrifuges are now widely used throughout the pharmaceutical industry, along with small centrifuges that spin at around 3000 rpm for blood separation, forming the entire system of low-speed industrial centrifuges. They have also penetrated into other industries related to biomedicine. Such centrifuges must comply with national GMP (Good Manufacturing Practice) regulations before they can be used.

4000 rpm/6000 rpm/8000 rpm/11000 rpm centrifuge provided by ATO industrial automation with exquisite appearance, small space occupation can meet different experimental needs, and is an ideal choice for laboratories, enterprises, classrooms, workplaces, etc. ATO microcentrifuges are widely used in the centrifugation of PCR experiments, medical cosmetology, micro blood cell isolation, and microbial sample processing.