High Speed BLDC Motor Performance Test

BLDC consists of motor and drive, which is a typical mechatronic product. It is composed of permanent magnet rotor, multi-pole winding stator and position sensor. Brushless DC motors (BLDC) feature high efficiency and excellent controllability, and are widely used in many applications. The BLDC motor has power-saving advantages relative to other motor types. Motor above 5000 rpm is a high speed motor, that is, brushless DC motor above 5000 rpm can be called high speed brushless DC motor.

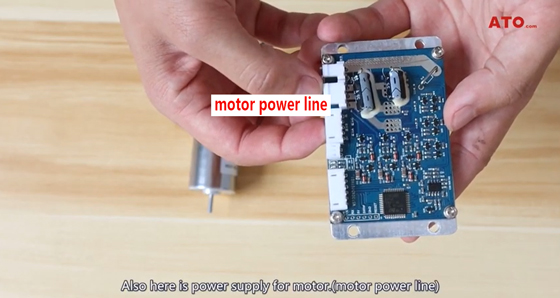

In this article, we will carry out high speed BLDC motor performance test. Here is power supply for motor. (motor power line)

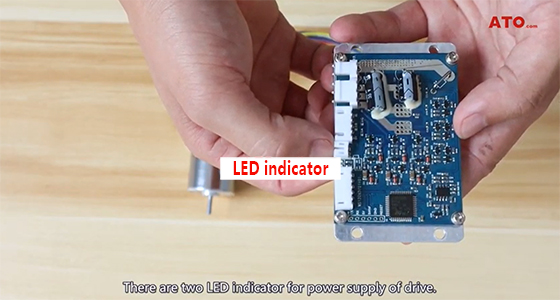

There are two LED indicator for power supply of drive.

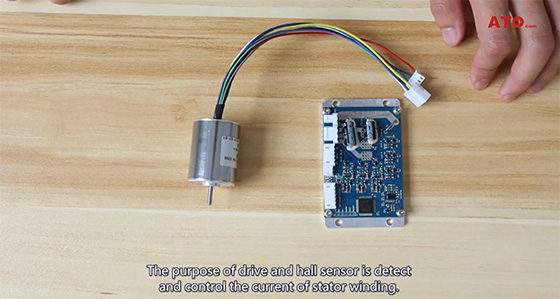

Here is control part (control section) for motor. The purpose of drive and hall sensor is detect and control the current of stator winding.

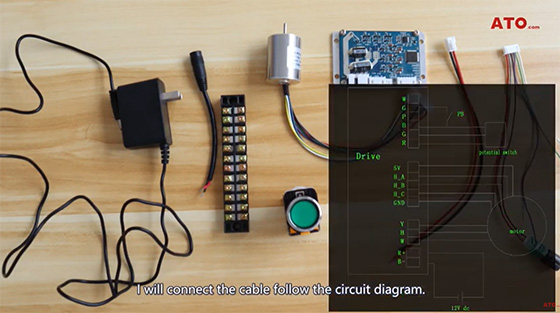

According to the change of rotor position, the hall sensor commutates the current of stator windings in a specific sequence. Next, connect the cable follow the circuit diagram.

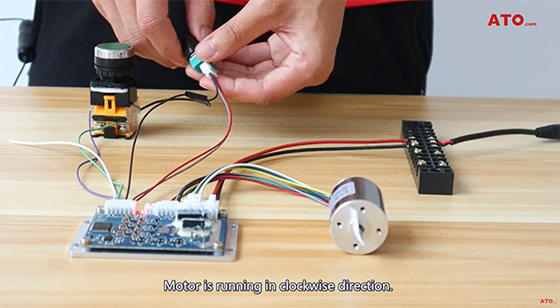

Switch on the power supply. There are two LED indicators. Motor is running in clockwise direction.

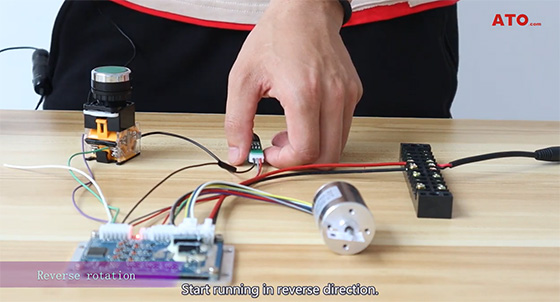

Now reduce the speed via potential switch and stop the motor in the end. Start running in reverse direction. We can see, mow the motor is running in anti-clockwise direction.

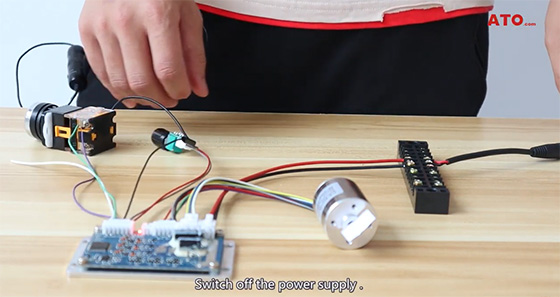

Switch off the power supply. This completes our test of the motor.

If you want to learn more information about high speed BLDC motor, please click this video or contact us.