How Does a Piston Pump Work?

An axial piston pump is a positive displacement pump with a plurality of pistons in a circular arrangement in the cylinder block. It can be used as independent pump, hydraulic motor or automobile air conditioning compressor. An axial piston pump has a plurality of pistons arranged in a circular array within the housing of the cylinder block, rotor, or cylinder.

The cylinder is driven by an integral shaft more or less aligned with the pumping piston to rotate about its axis of symmetry. In this article, we mainly introduce the working principle of piston pump.

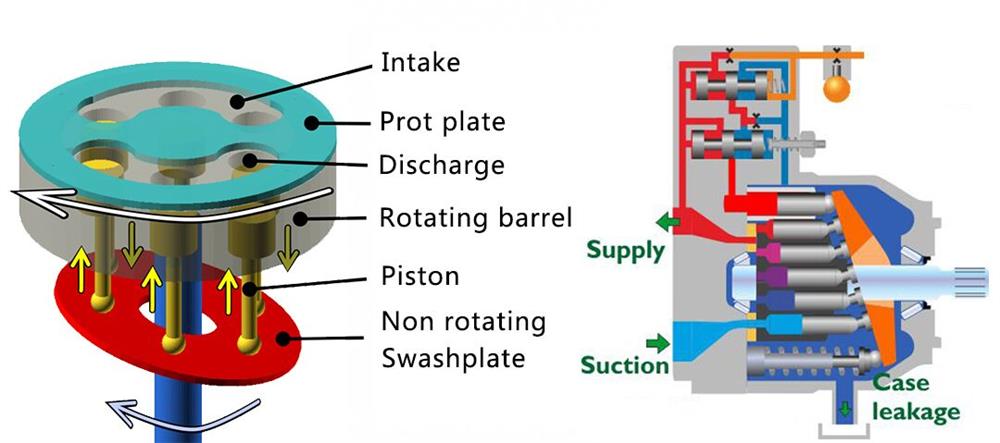

The driveshaft is coupled to a swashplate and rotating barrel. The swashplate adjusts itself based on the position of barrel and pistons. As shown in the figure, we have two colors for the inlet and outlet port. When the barrel rotates, the piston which is placed upside, and pressed inside and similarly the piston which is place downsides, is pressed outside. There is an inclination in the position of the swashplate. The same position is reversed for the next cycle of operation such that the location of piston completely forms a cycle. This helps in gas or liquids to be displaced from one location to other i.e. from the input port to outlet port.

The pistons rotate along with the barrel in line with the position of the swashplate. The pistons are placed inside a cylindrical block. The movement of the pistons causes a difference in pressure, which causes suction of the inlet liquid or compressed gasses. The inclination in the vertical position of the swashplate is up to 10 to 15 degrees. Because of this reason, it is called, axial flow and variable displacement piston.

The motion of the piston is called reciprocating motion. The continuous motion i.e. suction and discharge by the pistons cause the displacement in the liquid or compressed gasses. When the angle decrease, we have less suction, and when the angle increase we have more. For that reason, it is called a variable displacement piston. The variable displacement depends on the swashplate angle.