How Does Vibration Motor Controllers Work?

A vibration motor controller is a device used to control a vibration motor by adjusting parameters such as current, voltage, frequency, and phase to achieve precise control of the vibration motor. Vibrating motors are commonly used in industrial applications such as vibratory feeding, screening, conveying, etc. The principle of operation of vibrating motor controllers involves circuitry and signal processing, etc. ATO online shop provides you with a detailed introduction to the principle of operation of vibrating motor controllers.

Power Supply and Regulation

First, the vibration motor controller needs to be connected to a power supply to provide the required electrical energy. Typically, vibration motors require an AC power supply, so the vibration motor controller will convert the voltage from the DC power supply to an appropriate AC voltage to meet the vibration motor's operating requirements. This usually involves power converters, rectifier circuits, etc.

Vibration Motor

The vibration motor is the core component that generates the vibration force. Its structure includes a motor body and an eccentric mass block. The body of the motor is controlled by current to generate rotational motion, while the eccentric mass block will rotate with the motor and cause imbalance, thus generating vibratory force.

Frequency Adjustment

The vibration frequency of the vibration motor is determined by the frequency of the AC signal generated by the vibration motor controller. Typically, the vibration motor controllers have a variety of parameters for which options can be set, such as vibration frequency, vibration amplitude and vibration mode. Users can adjust these parameters according to the needs of specific applications. Vibration motor controllers can adjust the operating frequency of the vibration motor by changing the frequency of the output signal. Frequency adjustment is usually measured in Hertz (Hz).

Phase Adjustment

A vibration motor typically consists of two mutually perpendicular vibration sub motors that can operate at different phase differences to produce the desired direction of vibration. The vibration motor controller can adjust the phase difference between these two sub motors to change the direction and intensity of vibration.

Signal Generation and Transmission

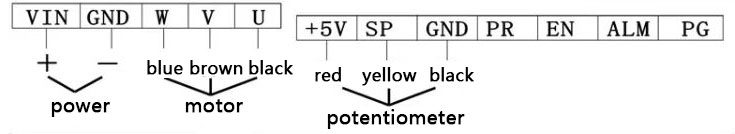

The vibration motor controller generates the appropriate control signals based on the parameters set by the user, and the generated control signals are transmitted to the vibration motor. This is usually achieved by connecting cables or wires. The characteristics of these signals determine the frequency and amplitude of the vibration generated by the vibration motor.

Amplitude Control

The amplitude of the vibration motor is the magnitude of the vibration or the magnitude of the vibration force. The vibration motor controller controls the amplitude of the vibration motor by adjusting the voltage or current of the output signal.

Feedback Mechanism

Some advanced vibration motor controllers have a feedback mechanism that allows the output signal to be adjusted according to the actual operating conditions of the vibration motor to ensure that the desired vibration effect is achieved. This feedback can come from acceleration sensors, displacement sensors, etc., which are used to monitor the operating status of the vibration motor and automatically adjust the control parameters as needed to maintain a stable vibration effect.

Protection Functions

Controllers are also usually equipped with several protection functions to prevent vibration motors from being damaged due to overcurrent, overload, overheating, and other problems. These protections ensure that the vibration motor operates within safe limits and extends the life of the motor.

User Interface

Some vibration motor controllers feature a user interface, such as a panel, touch screen, or remote control interface. The user interface allows the user to set and adjust vibration parameters. This can be physical buttons, knobs, or more modern touchscreen interfaces. The interface allows the user to select the desired vibration frequency, amplitude, and operating time to suit different applications.

Overall, vibration motor controllers achieve precise control of vibration motors by adjusting power parameters, frequency, phase, and amplitude to meet the vibration needs of different applications.