How to Choose a Linear Rail?

Linear rails, also known as linear guideways, are used for high-precision or high-speed linear reciprocating motion and can bear a certain torque. It enables high-precision linear motion under high loads. Linear guideways are used to support and guide moving parts and perform reciprocating linear motion in a given direction. Like the high requirements of all precision parts, its selection needs to be considered from the following three aspects.

Features

At present, common types of linear guides include ball linear guides, roller linear guides and cylindrical linear guides. Their application range and applicable conditions are different, and they can be selected according to their characteristics. Linear rails can be divided into roller linear guides, cylindrical linear guides, and ball linear guides. According to the nature of friction, linear motion guideways can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, etc. 300mm ~ 1500mm CNC linear rails with a guide block are available on ATO store.

Ball Linear slide

- High precision and heavy load-bearing

- Higher cost

- High rigidity in all directions

Roller linear guideways

- High speed and low noise

- Corrosion-resistant and not easy to rust

- Simple maintenance and easy replacement

- Small error and good precision

- Light load

- The scope of application is relatively limited

Cylindrical linear rail

- Round sliders are suitable for special occasions

- It has the ability of self-aligning

- Cheap and low precision

Parameter

There are many kinds of linear guide rails on the market, which not only provide us with a wide choice of space but also puts forward a test for the professional degree of users. Generally, we need to provide the necessary parameters to the supplier, which is an important reference.

- Conditions of Use: We all know that the use of linear guides is very extensive. Now there are many kinds of machine tools and equipment, and the machining accuracy of each machine tool is different, which leads to different linear guides used. The rougher the machine, the larger the slides used, and they are quite bulky. On the contrary, the higher the machining accuracy of the machine tool, the more high-precision guide rails are used. The user must provide this to the seller.

- Load capacity: When the load capacity is known, it is possible to decide which slider to use. The slider is an important part of the linear guide, which is directly related to the accuracy level of the slider, so its selection should be very careful. The load capacity also means how much weight the slider can bear, which is related to the safety factor when the slide rail works.

- Life expectancy: This is an important factor that affects the price of linear guides and is very important. You can consult the supplier about the expected service life of the linear guides before purchasing. Only linear guide products with good service life can maintain the stable operation and efficiency of the equipment.

Shape

In addition, we can also choose from the shape according to the actual needs, there are two kinds of linear guide rails: round and square.

Circular rail: It is used in conjunction with a linear bearing and a linear shaft. It is cylindrical in appearance and can be assembled into a circular hole. At the same time, the linear bearing can also be used with the slider to achieve plane installation. The installation and use of circular guide rails are more convenient and space-saving.

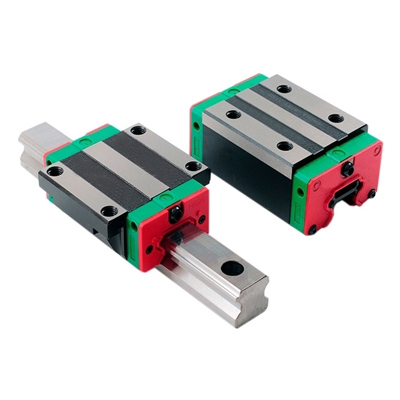

Square rail: It is used in conjunction with a square slider and a square rail, which is square in appearance. From the point of view of friction and load-bearing capacity, the square guide rail is the friction between the guide rail and the slider surface, the friction force is large and the load is even, but it needs to be lubricated frequently.

On the whole, the typical application of square guide rails is the machine tool industry which requires high load capacity, rigidity and accuracy. However, the installation requirements are high and the cost is high. The circular guide rail has its advantages in this regard, and it can still run smoothly even when it is installed on a surface that is not smooth. In general, round rails allow for faster installation and smoother operation than square rails.