Tips for Installing the Linear Scale

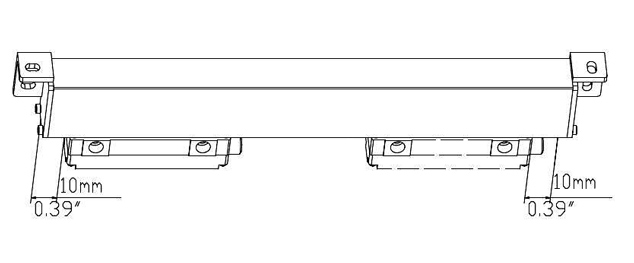

The effective movement of the linear scale should be larger than the maximum travel of the worktable. If it is not long enough, change a longer one or install fixing blocks on the worktable. Not less than 10mm space should be spared between the end of the Read Head and the body of the scale.

As to the installation surface of the linear scale, if it is not a mechanical work surface, you should place a cushion on the back of the scale or a self-made installation cushion. Only in this case can ensure the stability and reliability of the linear scale and installation surface.

When you calibrate the parallelity of the body of the digital linear scale with a level meter or other similar devices, the angle of the measuring head must be confined to +30 (based on the measuring head of the level meter being parallel with the level meter itself). As for the angle, the smaller, the better. If you use the decimal meter, you must make the bar of the measuring head perpendicular to the surface to be measured, only, in this case, can ensure the actual measuring precision. Please closely consider the following factors when selecting the position where the linear scale is to be installed:

- Select mechanical work surface as the installation surface.

- The groove of the linear scale must avoid the direct shock of metal powder, oil, water and dust.

- The length of the L-board, in the possible conditions, the shorter the better, and the bearing pressure of the installation surface of the L-board must be taken into close consideration, as well as the L-board Seri -al Read Head and the interface of the moving worktable.

More than 0.5mm space must be spared between the dust-proof cover and the body of the scale. Allow no contact between them when moving the scale.

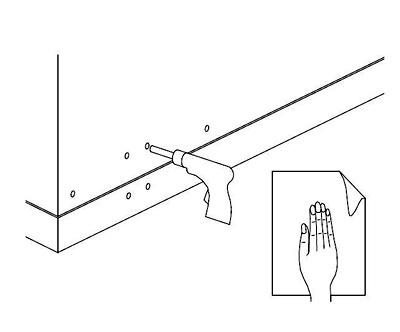

The screw thread of the installation hole must have at least, a 6-threading die screwing depth. The part which bears more pressure, such as the fixing board for supporting the DRO, must have, at least, an 8-threading die screwing depth. WTA series linear scale is tightened with M4 screw, and WTB with M5. After drilling holes on the installation surface, you have to smooth the granulated surface and clean the paint and the stains.

You must consider all the relevant moving distances before fixing the signal cable. The fixing position should be placed in the middle of the track as possible as you can. And then well bundle the surplus cable.

Make sure that the ground wire is grounded, and measure from the cover of the Read Head to the ground terminal of the signal processing device with a volt-ohm meter (the ground connector of the DRO). confirm the resistance is not more than 0.30 (Resistance≤0.30).

Based on the center of the linear scale, you must take the point of symmetry of the two sides as the criteria point when adjusting the height and level of the linear scale. As to any linear scale, whenever you perform the horizontal adjustment or vertical adjustment, for the body of the linear scale itself, the range of the adjustment can't individually exceed 20mm from the end of the meter to the body of the scale. As for the Read Head, perform the adjustment within the two square standard sides.