How to Install Noise Sensors?

Noise sensors play a side critical role in modern life, they are used to measure noise levels in the environment to protect human health and safety. Installing noise sensors is an important task, especially in a variety of situations where ambient noise levels need to be monitored, such as urban transportation, industrial areas, and communities. For those considering the installation of noise sensors, there are several issues to be aware of that may affect the performance and accuracy of the sensors, below is a list of relevant issues to be aware of from ATO shop.

Installation Location

Before installing a noise sensor, it is important to first carefully select a suitable location. The ideal location should be close to the noise source while avoiding obstruction and shading. If it is used for urban noise monitoring, consider choosing a location close to intersections, public transportation stops, or industrial areas. Ensure that the noise sensor is away from obstacles that may affect accuracy, such as buildings or large trees. The location of the noise sensor is particularly critical to obtaining accurate data. Noise sensors should be mounted in an area adjacent to or close to the noise source to ensure that they can see the full range of noise events. The location of the noise sensor should be a priority, taking into account whether it is likely to be obscured or obstructed.

When choosing a mounting location, consider the surrounding environment. Avoid installations in locations that are susceptible to weather, such as exposed areas to heavy rain or high winds. If installed outdoors, a waterproof enclosure is recommended to protect the sensor from harsh weather conditions. Also, try to select the same height to mount the sensor as the measurement noise event, which will maximize the accuracy of the data.

Target Usage Scenarios

There are many possible scenarios for installing noise sensors, and different scenarios require different sensor models and technologies. For example, in particularly noisy environments (e.g., around mechanical equipment or near highway speeds), the sensor needs to be able to detect volume levels up to 140 dB. Whereas in quieter environments (such as offices or schools), the need for data collection and recording is relatively low.

When mounting the noise sensor, ensure that it is securely fastened in its chosen location. Use appropriate brackets or fixtures to prevent the noise sensor from swaying or moving in the presence of wind or other external forces. Secure fixing ensures the stability of the sensor, which improves the reliability of the data. Before selecting a sensor, consider the noise level of the scene and determine whether features such as audio recording or single noise data measurements need to be supported.

Data Recording and Processing

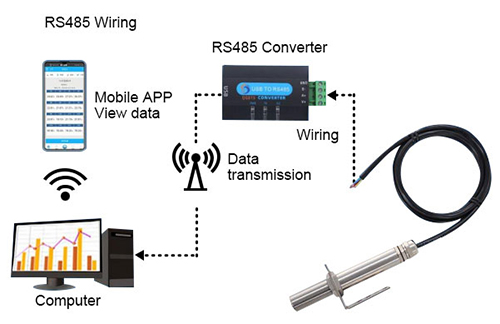

Once the installation is complete, connect the noise sensor to the appropriate data acquisition system. This can be a monitoring station, computer, or cloud platform, depending on your monitoring needs. Make sure the connection is stable to ensure real-time data transmission and analysis. Data logging and processing of noise sensors will have a direct impact on the accuracy of the noise data obtained. Storing and clearing records on time is a critical part of the process used to keep the records accurate to ensure the accuracy of the accumulated data and to steer clear of recording errors. Additionally, warning thresholds need to be set so that warning messages can be processed when the noise is outside the presumed range.

Calibration Process

Before officially using a noise sensor, it is important to perform a calibration. Calibration is a critical step in ensuring that the sensor accurately measures noise levels. Use specialized calibration equipment and follow the guidelines provided by the manufacturer. Calibration helps the sensor to adapt to a particular environment and improves the accuracy of the measurements. Noise sensors can become less accurate over time, which requires regular calibration. Calibration usually involves using the sensor with a known standard noise source and adjusting the sensor to ensure that its output is within tolerance. Calibration also includes a record of any adjustment operations so that it can be used to compare data before and after.

Power Supply Requirements

Noise sensors typically use batteries or AC power, so the technician should know which power supply is included with the sensor and how often the batteries need to be replaced or the AC batteries recharged. In addition, different sensor styles and features may require more or less energy, so a thorough evaluation of the power supply requirements of the selected sensor is needed before use.

Measuring noise monitoring instrument performance and variety varies greatly, and instruments used for environmental noise monitoring should have at least a time-averaged integration function, i.e., at least the ability to measure the equivalent continuous sound level Leq value, which is sufficient for environmental supervision departments. However, for environmental monitoring stations that require traffic noise measurements or noise census, there should also be statistical sound level LN (N=5, 10, 50, 90, 95) measurements and 24-hour monitoring functions.

To reduce manual recording and facilitate further data processing, often also needs to be equipped with micro-printers and data transfer to the computer and data storage and other functions, taking into account the social life of the noise in the low-frequency components of the noise is more difficult to evaluate the impact of its sound level on people, so in the measurement of the A sound level at the same time, but also on the noise of the octave spectral analysis, and then use the NR curve to measure the sound pressure level of each octave band whether it is within the allowable range. This requires the use of noise spectrum analysis measurement instruments with octave or 1/3-octave filters.

Regular Maintenance

Regular maintenance of the noise transducer is essential to ensure its long-term stable operation. Periodically clean the surface of the sensor, and check the sensor's power supply and connecting wiring to ensure that it is working properly. Regular maintenance extends the life of the good quality noise sensor and reduces the risk of failure in data acquisition.

Once the noise sensor is functioning properly, data can be monitored and analyzed. Use specialized analysis tools to monitor changes in noise levels and take appropriate control measures as needed. The analysis of noise monitoring data can provide an important reference for urban planning, environmental management, and public health.

Before selecting a noise sensor and performing the installation, thorough consideration needs to be given to the noise source, the target usage scenario, data recording and processing, calibration process, and power supply requirements. Careful evaluation of these issues will improve the performance and accuracy of the sensor and ensure data precision. During the installation of a noise sensor, always be safe and follow the specific guidelines provided by the manufacturer. With careful installation and maintenance, noise sensors will become a powerful tool for environmental monitoring and noise control, contributing to an improved quality of life and urban environment.