Noise Sensor Basics: Principles and Applications

The rhythm of life with the development of the new century has become faster and faster, in the modern busy city, those who are busy working all day long people want to get off work to return to a quiet and comfortable home to relax mood of the day, due to the city's transportation, entertainment, construction and other facilities to produce noise but scattered in every corner of the city, which makes the original rest of the home is also subjected to the interference of noise. A noise sensor is a sensor that measures the level of environmental noise. Noise sensors are sensors that convert ambient acoustic signals into electrical signals, which can be used to assess the level of noise. ATO store will introduce the principles of noise sensors and their application areas.

The Simple Principle of Noise Sensors

The working principle of a noise sensor can be divided into two steps: Sound reception and signal conversion.

- Sound Reception: Noise sensors usually use a microphone as the sound-receiving device. Sound is a mechanical wave, when the sound wave is transmitted to the microphone, it will make the membrane in the microphone vibrate. The vibration of the membrane in the microphone produces a sound pressure signal that varies with the strength of the sound.

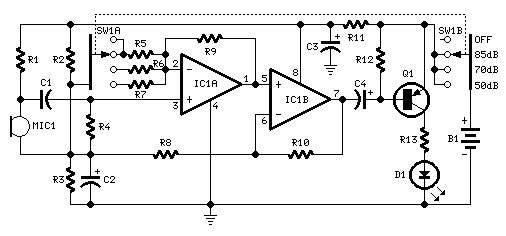

- Signal Conversion: The noise sensor converts the sound pressure signal received from the sound into an electrical signal. Typically, the microphone converts the sound pressure signal into a voltage signal in a transformer. The voltage signal in the transformer can be changed according to the strength of the sound. Next, this voltage signal goes through an amplification circuit that amplifies the signal to the right range.

The Details of the Working Principle

The noise sensor is built into a sound-sensitive capacitive electret microphone, and the sound wave vibrates the electret film inside the microphone, resulting in a change in capacitance and a corresponding change in voltage, thus realizing the conversion of optical signals to electrical signals. Noise sensor is precisely due to the sensor built-in a sound-sensitive capacitive electret microphone, electret surface, and back electrode relative to the center of a small air gap, forming an air gap and the electret as an insulating medium, to the back electrode and the electret on the metal layer as the two electrodes constitute a flat capacitor. An output electrode is provided between the two poles of the capacitor.

Due to the distribution of free charges on the electret film. When the sound wave caused by the electret film vibration and displacement, the distance between the two poles of the capacitor version, thus causing the capacitance of the capacitor capacity changes, because the number of charges on the electret body is always constant, according to the formula: Q=CU so when C changes must cause changes in the capacitor voltage U on both sides of the change, thus outputting an electrical signal, to realize the sound signal to the transformation of electrical signals.

The total charge of the electret is unchanged, when the pole plate in the acoustic pressure is back, the capacitance decreases, and the voltage between the poles of the capacitor will be inversely proportional to the rise, and vice versa, when the capacitance is added to the capacitance of the voltage between the poles of the capacitor will be inversely proportional to the decrease. After the field effect through the impedance is particularly high will be taken out of the capacitor voltage at both ends, while amplification, so you can get and sound corresponding to the voltage. Because the field effect tube active device, needs to determine the bias and current to work in the amplification state, therefore, an electret microphone should be added to a DC bias to work.

Detection of Noise Sensor

The principles and operation of the sensor can be detected with a multimeter can be good or bad. Noise sensor manufacturers factory supply sensor output sensitivity and supply voltage, based on these two parameters to detect the sensing output signal. Strain gauge load cell output analog signal millivolt voltage. For example, the noise sensor output sensitivity is 2.0mV/V, the supply voltage is DC10V, the two parameters can be supplied to the noise sensor excitation voltage is required to DC10V, the sensor output signal corresponds to every 1V excitation voltage output 2.0mV linear relationship. For example, if the noise sensor full scale is 50kg, then give the sensor DC10V voltage full-scale output of 20mV. based on this relationship can be measured with a multimeter mV gear sensor output signal. The noise sensor no-load output is 0mV normal, greater than this value, but close to this value, the value of change is the sensor has zero drift. If the value is very large suggests that the sensor is damaged or the internal bridge is the circuit, and the bridge arm resistance is not symmetrical.

According to the noise sensor factory supply sensor parameters, input resistance and output resistance to determine whether the sensor strain gauge is damaged. The sensor input and output resistance values of each manufacturer are not the same specifications. So this should be tested by the manufacturer's labeling. With a multimeter ohm gear detection, power supply, power ground resistance, signal line, and signal ground resistance. If the resistance value is larger than that of the factory the noise sensor has been overloaded with strain gauge deformation, if the resistance value is infinite, the noise sensor strain gauge is seriously damaged beyond repair.

As the noise sensor is often used in the process of lead pulling off, and the outer layer of the sheath line is intact, so the visual sensor wire is intact, we use the multimeter's ohm gear to detect the sensor wire through the break. If the resistance is infinite to determine the fracture, if the resistance changes poor contact.

Noise Sensor Applications

- Environmental Monitoring: noise sensors can be used for environmental noise monitoring, such as urban traffic noise, factory noise, and so on. By monitoring the noise level, you can assess the degree of impact of environmental noise on people, and take appropriate measures to improve the environment.

- Industrial Safety: Noise is a common hazardous factor in the industrial production process. Noise sensors can be used to monitor noise levels in factories to ensure the auditory safety of workers. When noise levels exceed safety standards, timely measures can be taken, such as wearing earplugs or soundproofing equipment, to reduce workers' noise exposure.

- Health Assessment: Noise sensors can be used for health assessment, especially for those who are sensitive to environmental noise, such as the elderly, children, and the sick. By monitoring noise levels, the impact on people's sleep, blood pressure, and heart can be assessed, as well as taking appropriate measures to protect people's health.

- Smart Home: Noise sensors can be used in smart home systems to realize automated control. For example, when the noise level exceeds a certain threshold, the volume of the home audio system can be automatically adjusted or the noise source can be turned off to provide a quieter living environment.

A noise sensor is a sensor used to measure the level of ambient noise. It evaluates the strength of the noise by converting the sound pressure signal received from the sound into an electrical signal. Noise sensors are widely used in environmental monitoring, industrial safety, health assessment, and smart homes. With the continuous progress of science and technology, the accuracy and reliability of noise sensors will continue to improve, providing us with a better living and working environment.