The Analysis of Line Reactor Noise

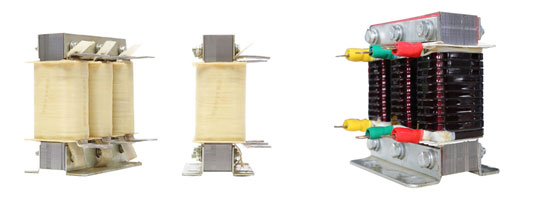

The noise of the line reactor is mainly caused by the magnetostriction and interslice vibration of the silicon steel sheet. Moreover, because of the alternating magnetic field attractive force between the iron core sheets, the noise of the reactor is 10dB or more higher than that of the transformer with the same capacity. However, the ordinary technology will promote the reactor noise to reach the standard requirement. The abnormal reactor noise in the operation site is mainly caused by the inconsistent height of the three phases of the iron core column, and even the difference is great.

However, there is no such vibration reduction measures such as being padded with the felt, resulting in the gap between the iron core sheet and upper iron yoke of a certain phase. Or because the levelness and straightness and other tolerance aspects are not strictly guaranteed in piling the iron core sheet. Because it fails to reach the technology requirement, the iron core sheet is inclined, and there is a gap among the sheets in the inclined areas. All the above reasons will result in the high abnormal noise of the reactor.

The great noise of the reactor might be caused by the following reasons:

One of the other manufacturing reasons for the high noise of the reactor lies in the insufficient clamp force of the iron core. The low iron core fastening force will increase the operation noise of the reactor. As the experience indicates, when the pressure intensity of the iron core clamp force is 0.8~1.2MPa, the noise of the reactor is the lowest. In addition to this, the compression screw and clamp nut of the iron core sheet should be equipped with an additional lock net, preventing from the looseness of the nut caused by the vibration of the iron core sheet in operation, so as to result in the high noise degree.

- Power harmonic: The current of the reactor input terminal has rather serious surge phenomenon, or the current change is rather serious.

- Silicon steel sheet: The silicon steel sheet of the reactor should be overlaid smoothly and orderly. The noise is easily to be caused if if the silicon steel sheet is not piled tightly.

- Coil: The gap caused by the internal looseness of the coil will generate great noise greatly.

- Immersion: If the paint immersion is not thorough or the time is too short, there might be missed immersion or insufficient immersion thickness.

- Fastener: If the screws on the reactor have looseness, it is easily to generate noise.

- Power: The capacitor has too small capacity(low possibility). To sum up, if your line reactor has reliable quality(low power harmonic mutation, smooth silicon steel sheet arrangement, thorough immersion and appropriate thickness and so on), and the parameter of the output power is consistent with the load, there will be no problem of noise.

If the silicon steel sheet has low processing accuracy, serious rags in the manufacturing process, or the silicon steel sheet has bump, or the silicon steel sheet is not rolled in parallel of the magnetic flow direction, or the insulation between the iron core sheets is broken, the iron core is earthed in several points, or the nut is not tightened, all these will increase the noise of the reactor in different degrees.

The reactor is different from the transformer. There is a kind of alternating attractive force existing between the iron steel sheets because of the air gap, so its noise is higher than the transformer with the same capacity. In design, the magnetic flux density of the reactor should not be too high, which is usually valued below 1T. In addition, the main magnetic flux density is better to be lower than 0.9T. If the magnetic flux density is valued too high in design, the noise will be increased for 2~3dB if the magnetic flux density rises by 0.1T.

In addition, if the designed magnetic flux density is too high, the unit iron core loss in the iron core sheet increases, thus resulting in the too high temperature of the iron core. If the temperature exceeds F grade thermal resistance temperature and it is operated for a long period, F grade insulation of the air gap piece will be aged and damaged slowly, and the noise will be increased accordingly.