How to Use a Sliding Vane Pump?

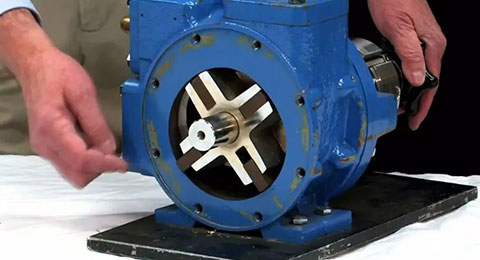

Sliding vane pump is a commonly used hydraulic pump, mainly employed for transporting liquids or compressing air. It consists of components such as the pump body, slide, and piston, with liquid intake and discharge achieved through the up-and-down sliding motion of the slide. In this article, ATO industrial automation will introduce the usage method about the sliding vane pump for you.

Preparation Before Using the Sliding Vane Pump

- Check the tightness of all connecting bolts on the sliding vane pump, inspect for any leaks at various interfaces, examine the anchor bolts for signs of loosening, and ensure the grounding is in good condition.

- Inspect the installation and tension of the V-belt. Rotate the pump 2-3 times and check for any sticking or binding in the pump's rotation.

- Check the lubrication of the bearings, ensuring it is normal. For pumps that have been unused for an extended period or newly installed pumps, add lubricating grease as required before starting.

- Examine the normalcy of pressure gauges and other components on the inlet and outlet pipelines. Check the electrical system for proper functioning.

- For newly installed or recently repaired pumps, individually jog the motor to confirm that the motor and pump rotation directions match the specified markings.

- Open the inlet valve, open the exhaust valve, and prime the pump, attempting to remove as much air from the pump as possible.

- Confirm the opening of the inlet and outlet valves of the sliding vane pump, ensuring the process flow is established both before and after the pump.

Steps for Using the Sliding Vane Pump

- Once all relevant professionals confirm completion, start the pump. While monitoring the pressure, close the reflux valve and observe the pump's operation.

- After the sliding vane pump is started, check the outlet pressure, ensuring it falls within the specified performance range.

- Inspect the operation of the sliding vane pump, ensuring there is no sharp noise or intense vibration.

- During continuous operation, check whether the bearing end cover temperature is normal, not exceeding 40°C above ambient temperature. It should not be too hot to touch by hand; otherwise, the pump should be stopped for inspection.

- During operation, operators must not leave the site. Monitor the pump's operation, regularly check the pump casing, and observe if there are any temperature changes. If any abnormalities are detected, investigate immediately.

- Stop the pump first, then close the outlet valve or inlet valve. For pumps that will be unused for an extended period, drain the liquid from the pump, wipe the internal and external rotors dry, and store them.

Precautions

- During the operation of the sliding vane pump, regularly inspect the pump's working condition. Address any anomalies promptly.

- Avoid continuous operation of the sliding vane pump for extended periods. Implement appropriate intermittent work to prevent damage to the pump body.

- If the pump body heats up or produces unusual sounds during use, stop using it immediately and investigate the cause of the malfunction.

- Ensure that the temperature and viscosity of the liquid meet the requirements of the sliding vane pump to avoid malfunctions due to inappropriate liquid properties.

- Before using the sliding vane pump, undertake thorough preparations to ensure the integrity of the pump body and connecting pipelines.

- Exercise caution and prioritize safety when using the sliding vane pump to prevent leaks or spills, avoiding personal injury or environmental contamination.

Maintenance and Care

- Regularly clean the pump body and slide of the sliding vane pump to ensure there are no impurities or residual contaminants.

- If the sliding vane pump is not used for an extended period, apply rust prevention treatment and store it in a dry and well-ventilated location.

- The lubricating oil of the sliding vane pump should be changed regularly to avoid affecting the pump's lifespan due to oil degradation.

- Periodically check if any components of the sliding vane pump are loose. If any looseness is detected, tighten it promptly.

- If any faults or abnormalities are found in the sliding vane pump, stop using it immediately and contact after-sales service personnel for repairs.

The sliding vane pump is a commonly used hydraulic pump that requires preparation before use and attention to safety and maintenance. By adjusting the positions of valves and slides, liquid intake and discharge can be achieved. The sliding vane pump is suitable for transporting liquids or compressing air, and the appropriate model and material should be selected based on specific work requirements. In case of any abnormalities during use, stop using it promptly and take corrective action. With correct usage and maintenance, the sliding vane pump can maintain good working condition and extend its service life.