How to Use CNC Router Machine?

What is CNC Router Machine?

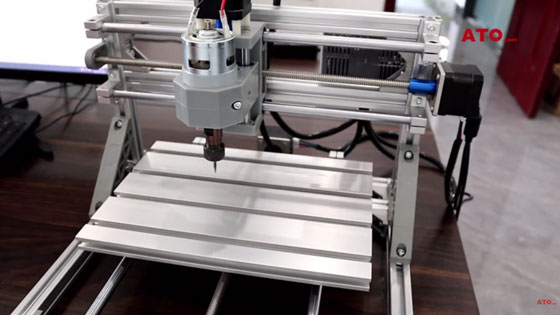

Computer Numerical Control (CNC) routers are a class of machine shop equipment used to remove material from specific locations on wood or metal. Since each material has different advantages and disadvantages, there are different types of CNC milling machines. Computer numerical control refers to computer programming used to control and program routers. CNC routers are used to create patterns or cuts as needed. Industrial CNC routers used in factory settings are much more expensive than hobbyist models. CNC routers are attached to a table and programmed to remove material in a specific pattern or shape from a piece of wood or metal. The engraving machine is usually connected to a three-speed or four-speed motor system.

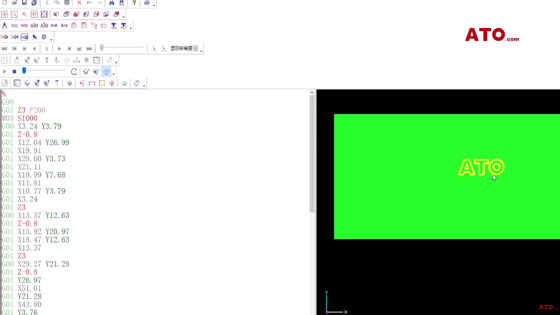

How to use CNC Router Machine?

A CNC machinist must be proficient in programming, testing, and adjusting equipment to produce the desired results. CNC routers designed for use with wood typically rotate at 13,000 to 24,000 revolutions per minute. Different substrates, templates or fixtures are used to create specific patterns in the wood. These parts are mounted on a tool holder, which is accessible via the spindle head. The spindle head tightens and releases to hold the tool used to cut the material. Different models of CNC routers offer a wide range of tool holding and changing systems. These systems are designed to allow machinists to quickly switch tool sets to meet different requirements. The more flexibility you have, the faster you can get work done.

When using a CNC router machine, there are two methods for protecting the material: pod-based suction or vacuum systems. Most routers only offer one method. Each method has a specific application that is more efficient. Suction cups are often used to hold material so that it can be moved and manipulated as needed. Suction-based systems are most practical when products require undercuts. Undercuts are grooves or troughs formed in solid material. Spoil or particle board is another vacuum suction method for low-density workbenches. This method allows the pieces to be placed anywhere on the table and held firmly in place by the vacuum suction created under the table top. This type of system is slightly more expensive than suction cups because the motor needs to generate more suction over a larger area.

Under normal circumstances, when using the router, it will not be used for too long, so the router will have a lot of time to "rest". However, ATO professional routers are different when using routers. Due to the needs of work, most of the time, the routers even need to run 24 hours a day, which puts forward higher requirements for the industrial design of routers.

The video below shows you the operation of the Mini CNC Router-Milling Machine.