Induction Motor Buying Guide

Induction motors are popular in the industry, since they are simple to build and economical. The following are some essential things you need to consider when buying an induction motor.

What is an Induction Motor?

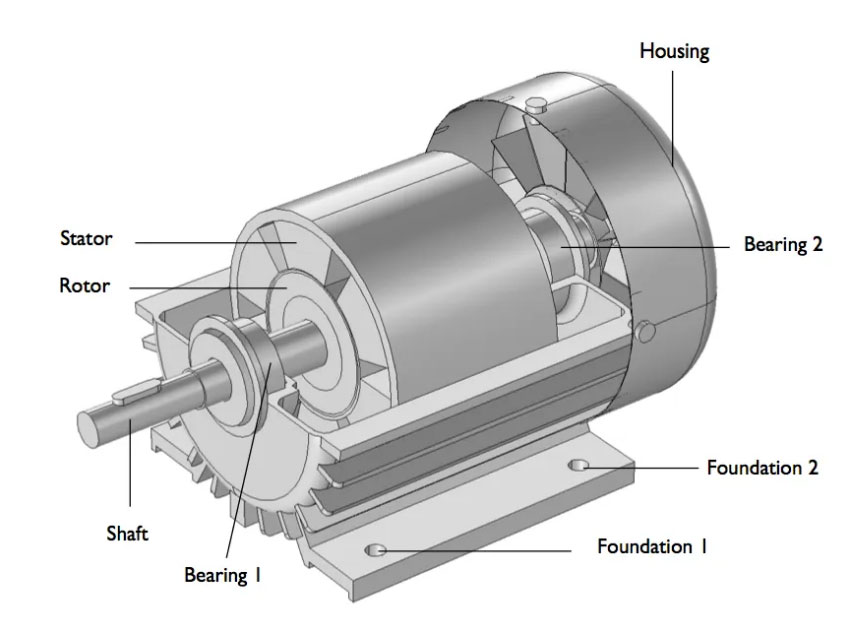

An induction motor or an asynchronous motor is an AC motor that works on the principle of electromagnetic induction. That is, the rotor obtains torque under the action of the rotating magnetic field generated by the stator, and then the rotor rotates. Since the rotor speed is not the same as the speed of the rotating magnetic field (synchronous speed), the induction motor is also known as asynchronous motor.

The rotor is a rotatable conductor, which is divided into squirrel-cage type and wound type according to the winding form. The stator is the stationary part of the motor which provides a rotating magnetic field. The rotating magnetic field is realized through the alternating current. When the current flows through the coil of the rotor, the properties of the magnetic poles are cyclically changed, which is equivalent to a rotating magnetic field. Depending on the the input supply, induction motors can be categorized into single-phase and three-phase induction motors.

Single-phase induction motors are squirrel-cage types, which are mainly used for small loads, such as fans, washing machines, refrigerators, air conditioners and other household appliances.

Three-phase induction motor rotors include squirrel-cage type and wound type. They are widely used as industrial drives due to its low price, sturdy structure, low maintenance cost, high efficiency, easy operation, reliability and durability.

Choosing an Induction Motor

When buying an induction motor, the primary concerns are speed, voltage, torque and power. Other things you've got to take into consideration are working system, overload requirements, insulation class, protection class, moment of inertia, load, installation method, maintenance, ambient temperature, altitude, enclosure rating, outdoor environments, energy efficiency, etc. Now, ATO provides you with its reliable and economical induction motors and helps you make best choices in your purchases.

An induction motor using a single-phase AC power supply is called a 1-phase induction motor. Because single-phase induction motors only need single-phase alternating current, they are easy to use and widely used, and have the advantages of simple structure, low cost, low noise, and little interference to radio systems, so they are often used in household appliances and small power machinery with low power. Among them, such as electric fans, washing machines, refrigerators, air conditioners, range hoods, electric drills and medical equipment.

An induction motor using a single-phase AC power supply is called a 1-phase induction motor. Because single-phase induction motors only need single-phase alternating current, they are easy to use and widely used, and have the advantages of simple structure, low cost, low noise, and little interference to radio systems, so they are often used in household appliances and small power machinery with low power. Among them, such as electric fans, washing machines, refrigerators, air conditioners, range hoods, electric drills and medical equipment.

Three-phase induction motor is a kind of induction motor, which is powered by three-phase AC current. Compared with single-phase induction motors, three-phase induction motors have better running performance and can save various materials. Three-phase induction motor are mainly used in excavation, fluid transportation and other fields that need to provide power, such as machine tools, small and medium-sized steel rolling equipment, fans, pumps, light industrial machinery, metallurgy and mining machinery, etc.

Three-phase induction motor is a kind of induction motor, which is powered by three-phase AC current. Compared with single-phase induction motors, three-phase induction motors have better running performance and can save various materials. Three-phase induction motor are mainly used in excavation, fluid transportation and other fields that need to provide power, such as machine tools, small and medium-sized steel rolling equipment, fans, pumps, light industrial machinery, metallurgy and mining machinery, etc.

Explosion-proof motor is a kind of motor that can be used in flammable and explosive places and does not produce electric sparks when running. Explosion-proof motors are mainly used in coal mines, oil and gas, petrochemical and chemical industries. In addition, in the textile, metallurgy, city gas, transportation, grain and oil processing, paper, medicine and other sectors are also widely used. As the main power equipment, explosion-proof motors are usually used to drive pumps, fans, compressors and other transmission machinery, etc.

Explosion-proof motor is a kind of motor that can be used in flammable and explosive places and does not produce electric sparks when running. Explosion-proof motors are mainly used in coal mines, oil and gas, petrochemical and chemical industries. In addition, in the textile, metallurgy, city gas, transportation, grain and oil processing, paper, medicine and other sectors are also widely used. As the main power equipment, explosion-proof motors are usually used to drive pumps, fans, compressors and other transmission machinery, etc.

The brake motor is a fully enclosed self-fan-cooled squirrel cage type three-phase asynchronous motor with an additional disc type DC brake. It is composed of a DC disc electromagnetic brake motor attached between the rear end cover of the Y series motor and the fan. It is a derivative series of the Y series. It has the advantages of rapid braking, simple structure, high reliability and strong versatility. Brake motors are widely used in various mechanical equipment and transmission devices that require quick stop and accurate positioning.

The brake motor is a fully enclosed self-fan-cooled squirrel cage type three-phase asynchronous motor with an additional disc type DC brake. It is composed of a DC disc electromagnetic brake motor attached between the rear end cover of the Y series motor and the fan. It is a derivative series of the Y series. It has the advantages of rapid braking, simple structure, high reliability and strong versatility. Brake motors are widely used in various mechanical equipment and transmission devices that require quick stop and accurate positioning.

A variable speed motor is a motor that changes the speed of the motor by changing the number of stages, voltage, current, frequency, etc. of the motor, so that the motor can achieve higher performance. Due to its excellent performance, variable speed motors have been widely used in steel, power stations, cables, chemicals, petroleum, cement, textiles, printing and dyeing, papermaking, machinery and other industrial sectors for stepless speed regulation of load machinery with constant torque or decreasing torque.

A variable speed motor is a motor that changes the speed of the motor by changing the number of stages, voltage, current, frequency, etc. of the motor, so that the motor can achieve higher performance. Due to its excellent performance, variable speed motors have been widely used in steel, power stations, cables, chemicals, petroleum, cement, textiles, printing and dyeing, papermaking, machinery and other industrial sectors for stepless speed regulation of load machinery with constant torque or decreasing torque.

The stainless steel motor is designed to avoid flats, cracks and crevices, preventing the accumulation of foreign objects and bacteria. Its housing and cables can withstand daily high pressure, high temperature and aggressive chemical washdowns. The robust design means the motor can be cleaned without the need for guards and covers to protect it. These features ensure faster cleaning, higher uptime, and higher overall line equipment efficiency.

The stainless steel motor is designed to avoid flats, cracks and crevices, preventing the accumulation of foreign objects and bacteria. Its housing and cables can withstand daily high pressure, high temperature and aggressive chemical washdowns. The robust design means the motor can be cleaned without the need for guards and covers to protect it. These features ensure faster cleaning, higher uptime, and higher overall line equipment efficiency.

Induction Motor Advantages and Disadvantages

Advantages:

- Various control methods: Since induction motor has no permanent magnet, it is easier to achieve different speeds and torques by weakening magnetic field or frequency conversion, etc. It can be used in industrial or domestic applications that do not require high torque density, and has the advantages of self-starting, economical, and reliable.

- Low cost: Induction motors are cheap compared to synchronous and DC motors. This is determined by the design of the induction motor. Therefore, induction motors are the first choice for fixed speed applications in industry, as well as for commercial and domestic applications where AC power can be easily connected.

- Low maintenance cost: The structure of the induction motor is simple, so the maintenance is also easy, which reduces the maintenance cost.

- Easy to operate: Induction motors are self-starting motors (runs on their own with alternating current). It operates easily since there is no electrical connector on the rotor.

- Speed variation: The speed variation of an induction motor is constant. Speeds vary by only a few percent from no load to rated load.

- High starting torque: Induction motors have a high starting torque, which allows a load to be applied before the motor starts. Three-phase induction motors have a different self-starting torque than synchronous motors. However, a single-phase induction motor has no self-starting torque and can only be rotated by using some auxiliary means.

- Durability: Another advantage of induction motors is durability, which allows the motor to operate for many years without any cost and maintenance.

Disadvantages:

Compared to permanent magnet motors, induction motors are less efficient because of the current heat loss caused by the induced current.