Vacuum Circuit Breaker Working Principle

"Vacuum circuit breaker" is named for the high vacuum of the arc extinguishing medium and the insulating medium of the contact gap after arc extinguishing. It has the advantages of small size and light weight. Vacuum circuit breakers are used for switching purposes in high voltage (HV) applications. Vacuum circuit breakers are more efficient, smaller and less expensive. VCB circuit breakers have a much longer lifespan than conventional circuit breakers and require little maintenance. Electrical vacuum breaker is ideal for typical utility and industrial applications.

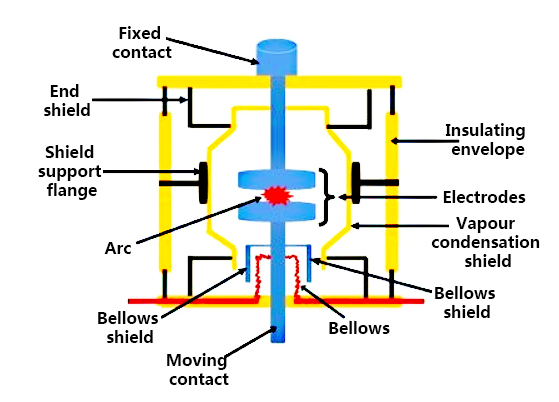

Compared with other circuit breakers, vcb breaker in ATO.com is very simple in structure. Its structure is mainly divided into three parts: fixed contact, moving contact and arc shield placed in the arc breaking chamber.

The outer envelope of vacuum circuit breaker is made up of glass because the glass envelope help in the examination of the breaker from outside after the operation. If the glass becomes milky from its original finish of silvery mirror, then it indicates that the breaker is losing vacuum.

The fixed and moving contacts of the vcb breaker are placed inside the arc shield. The vacuum interrupter is kept at around 10-6 Torr when it is closed. The moving contacts of the circuit breaker are move through a distance of 5 to 10 mm depending upon the operating voltage.

Metal bellows made of stainless steel are used to move the moving contacts. The design of the metal bellows is very important because the life of the VCB (vacuum circuit breaker) depends on the repeated operation capability of the element.

When the fault occurs in the system, the contacts of the breaker are moved apart and hence the arc is developed between them. When the current carrying contacts are pulled apart, the temperature of their connecting parts is very high due to which ionization occurs. Due to the ionization, the contact space is filled with vapour of positive ions which is discharged from the contact material.

The density of vapour depends on the current in the arcing. Due to the decreasing mode of the current wave, the rate at which they release vapor decreases, and after the current is zero, the medium regains its dielectric strength, provided that the vapor density around the point of contact decreases. Hence, the arc does not restrike again because the metal vapour is quickly removed from the contact zone.

This article introduces the working principle of vacuum type circuit breaker in detail. If you have any other questions, please contact us directly. ATO automation has professional technician to answer your questions.