VFD for incense stick machine

I. Overview

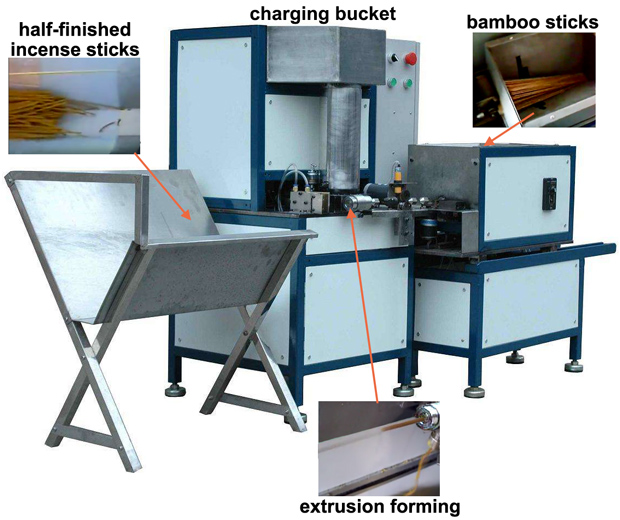

The incense stick industry has already had a history of nearly one thousand years. Affected by the Buddhism, the burning incense stick is even more prosperous than before, which has accelerated the fast development of the incense stick industry. Various incense sticks have different sizes, shapes and varieties. It has gone through numerous days from the purely hand-made incense stick at the very beginning to the automatically-made incense stick at present. The normal incense stick machine utilizes the hydraulic principle to complete the main work. Its fabrication method is quite simple and easy. Firstly, the hydraulic cylinder is used to propel the charging bucket full of incense materials. Then the incense materials in the charging bucket will be shot outside quickly through the installed model head because of the pressure, thus forming strips. Afterwards, workers will hold the bamboo sticks to send into the model head one by one with hands. When the bamboo sticks are inserted into the model head, the incense sticks will cover the sticks and shoot out of the model head continuously under the incense stick pressure. Till now, a half-finished incense stick has been completed. Then, they can be used after being settled and dried. Its electrical control is mainly used to control the stop and start of the hydraulic pump. It is very simple. The hydraulic pressure (which is exactly the speed of the incense stick) is adjusted by the pressure control valve. The electrical circuit only starts and stops the hydraulic pump forwardly. The up and down movements of the hydraulic cylinder can be realized through the circuit control of one 2-position and 4-way solenoid valve.

II. Technical problems and improvements of the incense stick machine

With the fast development of the incense stick industry, the demand is becoming greater. It is required to improve the output and quality. The hydraulic machine is no longer able to produce in high efficient. Furthermore, the material loading is rather troubling. The manual insert of the bamboo sticks is rather time and energy consuming. Therefore, it is necessary to increase the output and realize full automatic control to improve the efficiency and save labor cost. As a result, improving the incense stick machine to promote the working efficiency is vital.

Frequency conversion technology is utilized to realize soft start and soft stop. The characteristics of speed up and speed down are utilized to increase the start and stop time of the motor. Take the motor of 1.5kW as an example, the motor employs the slowdown motor with a reduction ratio of 1:10. Through the reversing gear, the motor will change from the revolving movement into the straight line movement. Each revolving will realize one pushing action. When the incense stick goes through the discharging bucket, the stirring device for discharging will be driven with the chain drive organization while the motor is revolving. The material pushing jacket will be filled with incenses and then be extruded outside through pushing. In addition, As to the pressure(discharging quantity), the operator can adjust the revolving eccentric wheel to change the journey of the material pushing jacket and increase its discharging space, thus achieving the pressure change. Completing the whole process only needs about 0.4s, then one incense stick is finished. The VFD has been debugged for incense stick manufacturing, so as to reach the manufacturing requirements thoroughly.

III. Parameter setting of ATO VFD

| Function code | Name | Set value | Remark |

| P0.01 | Frequency setting channel | 2 | Digital setting 1 |

| P0.02 | Running frequency digital setting | 5 | Digital setting 2 |

| P0.03 | Selection of operating command channel | 1 | Terminal operation |

| P0.06 | Maximum output frequency | 70 | Set according to the field condition |

| P0.09 | Torque rising | 8 | |

| P0.17 | Acceleration time 1 | 0.1 | |

| P0.18 | Deceleration time 1 | 0.1 | |

| P0.19 | Upper limiting frequency | 70 | |

| P2.05 | Halt mode | 2 | |

| P2.07 | DC braking time for halt | 0.1 | |

| P2.08 | DC braking voltage in halt | 2 | |

| P3.14 | Acceleration time 2 | 0.1 | |

| P3.15 | Deceleration time 2 | 0.1 | |

| P3.16 | Acceleration time 3 | 0.1 | |

| P3.17 | Deceleration time 3 | 0.1 | |

| P3.18 | Acceleration time 4 | 0.1 | |

| P3.19 | Deceleration time 4 | 0.1 | |

| P3.20 | Acceleration time 5 | 0.1 | |

| P3.21 | Deceleration time 5 | 0.1 | |

| P3.22 | Acceleration time 6 | 0.1 | |

| P3.23 | Deceleration time 6 | 0.1 | |

| P3.24 | Acceleration time 7 | 0.1 | |

| P3.25 | Deceleration time 7 | 0.1 | |

| P3.26 | Multistage speed 1 | 50 | |

| P3.27 | Multistage speed 2 | 60 | |

| P3.29 | Multistage speed 4 | 70 | |

| P4.02 | Functional selection of input terminal X3 | 01 | |

| P4.03 | Functional selection of input terminal X4 | 02 | |

| P4.04 | Functional selection of input terminal X5 | 03 | |

| P4.25 | Inspection level of overload pre-alarm | 180 | |

| P5.04 | Automatic current limiting level | 180 |

Buying an ATO VFD to increase productivity of your incense stick machine now, 1 hp VFD, 2 hp VFD, 3 hp VFD...