Vortex Flow Meter Installation

Vortex flow meter is a kind of flow meter that adopts the principle of Karman Vortex Street. It is used to measure the flow of liquids, gases and vapors, and it can also be used to measure turbid liquids containing small particles and impurities. It is widely used in petroleum, chemical, pharmaceutical, papermaking, metallurgy, power, environmental protection, food and other industries.

Working principle

The vortex flow meter is based on Carmen's vortex street theory. When the fluid flows through a non-linear triangular cylinder block, regular vortex signals are alternately generated on both sides of the block. The separation frequency of the vortex is proportional to the flow velocity of the fluid. The vortex separation frequency is detected by a piezoelectric ceramic element installed behind the block, thereby obtaining the fluid flow rate.

Installation guide

1. Installation site and environment selection

- Try to avoid strong power equipment, high frequency or frequency conversion equipment, and strong power switching equipment.

- Try to avoid the influence of high-temperature heat sources and radiant heat sources; if the flow meter is installed outdoors, shade and rainproof measures should be taken.

- Avoid vibration places and strong corrosive environments as much as possible, and also consider the convenience of installation and maintenance.

2. Appropriate installation position

- For the installation location of vortex flowmeter, try to avoid choosing pipes with strong vibration, otherwise vibration reduction measures must be taken, such as installing shock-absorbing short joints.

- The flow meter can be installed horizontally, vertically, and obliquely. When measuring liquids, you must ensure that the fluid flows from low to high. When measuring gas, the flow direction is unlimited. When measuring steam or high-temperature gas, the pillar of the watch body is at 45 ° to the vertical direction.

3. Vortex flowmeter piping requirements

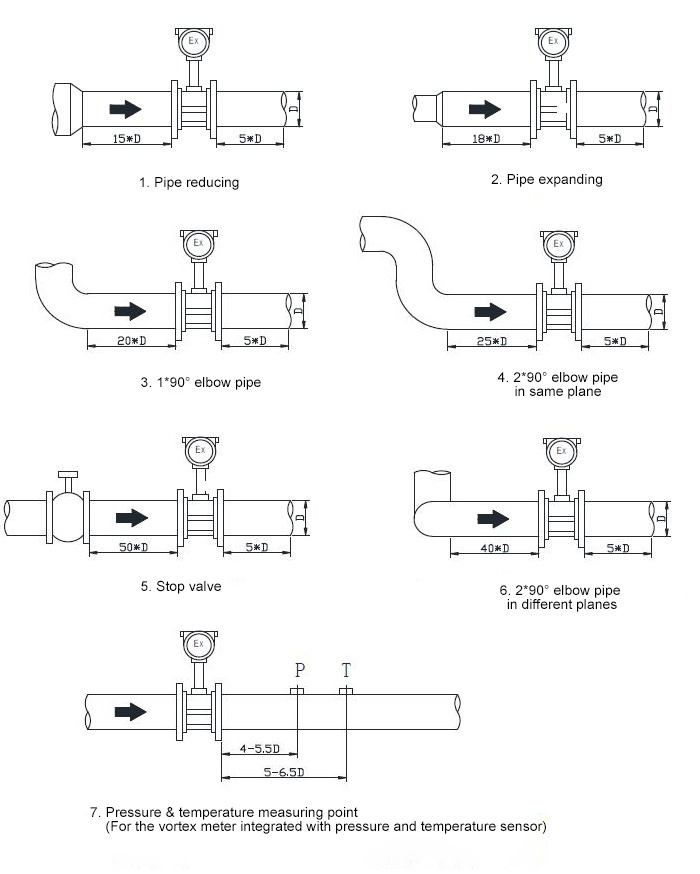

In order to measure accurately, there must be remaining enough straight pipe sections upstream and downstream of the flow meter installation site. There should be no components that affect the flow velocity distribution of the fluid in the upstream. The figure below shows the minimum straight piping length requirements before and after the flow meter under various pipeline conditions.

4. Grounding requirements

4. Grounding requirements

When the vortex flow meter is installed, the meter body should be reliably grounded. If the on-site pipeline does not have a grounding condition, a reliable ground wire should be separately connected to the ground terminal of the instrument case.

5. Installation method and welding

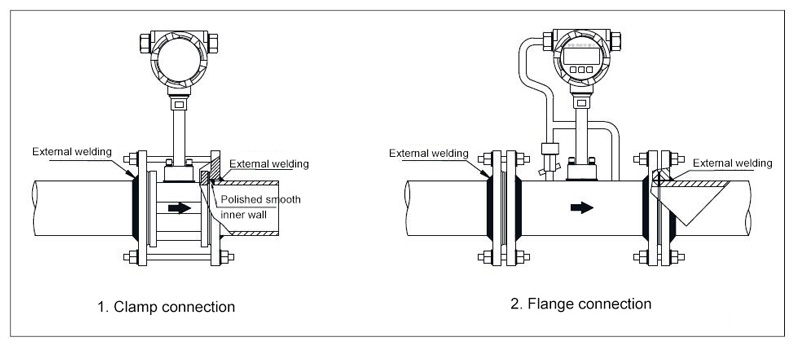

- The inner diameter of the upstream and downstream piping at the instrument installation point should be consistent with the inner diameter of the vortex flow meter, and the sensor should be concentric with the pipeline. The gasket between the sensor and the flange must not protrude into the pipe. The specific installation method is shown in the figure below.

- After the initial installation of the meter body, when the measuring medium is steam or other high-temperature medium, the flange bolts should be re-tightened after the pipe is filled with the medium. The pipe is insulated to avoid damage to the amplifier due to the high ambient temperature.

Please note that: For the vortex flow meter with integrated temperature and pressure compensation, to avoid damage to the pressure sensor due to high temperature or water attack, the pressure valve on the meter body must be closed before the pipeline is filled with fluid. When the pipeline is full of fluid and the working temperature and pressure are reached, the valve can be opened slowly. For the flow meter installed outdoors, the pressure bending pipe and pressure probe part should be insulated!

Please note that: For the vortex flow meter with integrated temperature and pressure compensation, to avoid damage to the pressure sensor due to high temperature or water attack, the pressure valve on the meter body must be closed before the pipeline is filled with fluid. When the pipeline is full of fluid and the working temperature and pressure are reached, the valve can be opened slowly. For the flow meter installed outdoors, the pressure bending pipe and pressure probe part should be insulated!