What Are the Types of Hoist?

The hoist is a compound sliding horse used to lift objects to a relatively low height, commonly known as a "chain block", and is a mechanical device used to lift and lower heavy objects. And the hoist is a small lifting tool with simple structure and convenient carrying. It is particularly convenient to use it in temporary chains and mobile locations, such as factories, mines, construction sites, docks, warehouses, etc., to lift small equipment and carry out equipment installation and repair work. There are various classification methods for hoists based on different product characteristics and application scenarios.

Classification According To the Drive mode:

According to the different drive mode, the hoist can be divided into electric hoist, manual hoist and air hoist. The electric hoist and manual hoist are the most widely used.

Electric hoist is a light and small lifting equipment that uses a motor as the power source and usually needs to be connected to a power source to work properly. The lifting capacityis generally 0.1-80 tons and the lifting height is 3-30 meters. It is composed of an electric motor, a transmission mechanism, and a drum or sprocket, and is divided into two types: wire rope electric hoist and ring chain electric hoist. Chain electric hoists are divided into two types: imported and domestic; The wire rope electric hoist is divided into CD1 type, MD1 type, micro electric hoist, winch, and multi-functional hoist. The electric hoist is commonly used in industrial, logistics, ports and other places.

The Advantages of Electric hoist:

- Fast improvement speed

- High efficiency

- Easy to operate

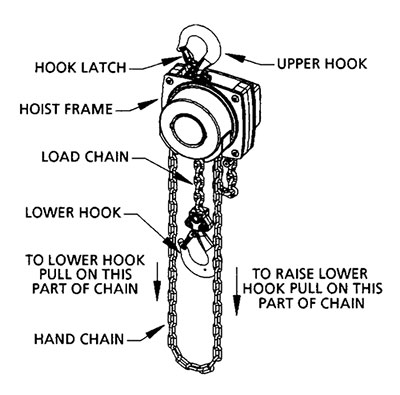

Manual hoist, also called fairy gourd, catty not fall and hand chain hoist, is a simple to use, easy to carry manual lifting tools, also known as "chain hoist" or "reverse chain". It is suitable for small equipment and goods lifting short distances, lifting capacity is generally not more than 100T. The shell material of the manual hoist is high quality alloy steel, which is sturdy and wear-resistant with high safety performance. Manual hoist is suitable for factories, mines, construction sites, wharves, docks, warehouses, etc. it used to install machines, lifting goods, especially for the open air and no power supply operations, as well as flammable and explosive places have its important role.

The Advantages of Manual hoist:

- Safety and reliability

- Easy to maintain and carry

- High mechanical efficiency

- It has small bracelet pull with light weight

- Beautiful appearance with small size

Air hoist is an upgraded product of electric hoist, which has been widely used in various industries, with a load range from 250kg to 30 tones depending on the model. Air hoist only need to provide a certain pressure of compressed air can be driven, to achieve low energy consumption, high efficiency. It also has the function of air break protection, which ensures that the workpiece will not fall down or drop in case of sudden air break. With a variety of non-standard fixtures, pneumatic hoists can lift various shapes of workpieces. The mounting form can be matched with cantilever crane or guide rail to realize the movement.

The Advantages of Air hoist:

- Low maintenance cost

- Compressed air does not produce sparks

- Variable speed control

- Dustproof and moisture-proof

Classification According To Lifting Capacity:

According to the size of the maximum lifting weight, hoist can be divided into small, medium and large.

Small hoist has a small size, light weight, simple operation, easy to use and other advantages, generally used in the family, agriculture and gardening and other places, the maximum lifting weight in a few tones below;

Medium-sized hoist has a moderate carrying capacity, easy to move, versatility and other characteristics, generally used in construction, logistics and ports and other places, the maximum lifting weight in the dozens of tones to dozens of tones ranging;

Large hoist has a high carrying capacity, stable structure, strong power and other characteristics, generally used in large-scale construction projects, iron and steel enterprises, petrochemical and other places, the maximum lifting weight in hundreds of tones or even thousands of tones.

In short, hoist, as a kind of mechanical equipment, have a wide range of application scenarios and a variety of classifications. ATO shop has a series of hoists for customers to choose from, customers can choose the right model according to the specific requirements of the work. In addition, it is very important to use hoists safely, as improper operation may lead to accidents and injuries. Therefore, operators usually need to be trained to follow safe operating procedures to ensure safety at the workplace.