What is a Hydraulic Bladder Accumulator?

ATO hydraulic bladder accumulator, also known as bladder accumulator or nitrogen accumulator, is an important component widely used in hydraulic systems. Its unique working principle and diverse applications allow it to play a key role in engineering, manufacturing and other fields. This article deeply discusses the principle, structure and application of hydraulic bladder accumulators to provide readers with a comprehensive understanding.

Basic Principles of Hydraulic Bladder Accumulator

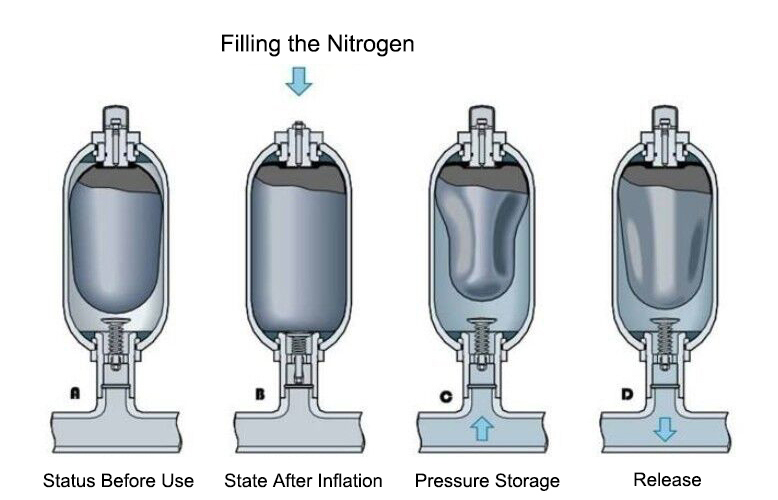

The basic principle of a hydraulic bladder accumulator involves the interaction of liquid and gas, whereby the compressible gas acts as a spring to store and release energy. Its core components include an outer metal container (usually steel) and an inner membrane made of rubber or elastic material that is filled with compressed air (usually nitrogen). When the system liquid passes through the hydraulic accumulator, the membrane is squeezed and compresses the gas, thus storing energy; when the energy needs to be released, the compressed gas pushes the membrane back to its original shape and transfers the stored energy to the liquid.

Structural Features

- Housing structure: The housing of a hydraulic bladder accumulator is usually made of high-strength steel to withstand the high pressure in the system. This ensures its reliability and durability in harsh environments.

- Membrane material: The internal membrane is usually made of rubber or other elastic materials, which have good elasticity and sealing properties. This ensures that the gas does not leak and that energy conversion can occur efficiently.

- Charging valve: To ensure that the gas inside the hydraulic bladder accumulator is fully compressed, a charging valve is usually equipped to adjust and monitor the pressure of the gas.

- Connection port: Hydraulic bladder accumulators are usually designed with standard hydraulic connection ports to facilitate connection with other components of the hydraulic system.

Application of Hydraulic Bladder Accumulator

- Energy balance and shock absorption: In hydraulic systems, hydraulic bladder accumulators are often used to balance the energy of the system, absorb and smooth pressure shocks, and improve the stability and efficiency of the system.

- Emergency shutdown and backup power: In some applications, hydraulic bladder accumulators can be used as a backup power source to ensure that the system can still maintain basic operation in the event of primary power failure.

- Industrial manufacturing: In some industrial manufacturing processes, accumulators can be used to smooth the movement of hydraulic systems, reduce vibration and shock, and improve production efficiency.

- Aerospace field: In aerospace engineering, hydraulic bladder accumulators are often used in aircraft landing gear and braking systems due to their lightweight and high-efficiency characteristics.

- Automobile industry: In automobile manufacturing, accumulators are widely used in braking systems to improve braking efficiency and system response speed.

To meet different engineering needs, various specifications of hydraulic bladder accumulators have emerged on the market. ATO online store provides hydraulic accumulators of various capacities, including 1 gallon (4L), 2-1/2 gallons (10Ls), 5 gallons (20L) and 10 gallons (40L) providing engineers and manufacturers with convenient choices.

-

1 Gallon (4L) Hydraulic Accumulator

It is suitable for small hydraulic systems, such as some light machinery and industrial automation systems. Its compact design and efficient energy storage capabilities make it widely used in scenarios with limited space. -

2-1/2 Gallon (10L) HydraulicAccumulator

The larger capacity accumulator is suitable for medium-sized hydraulic systems, such as medium-sized machinery and equipment, hydraulic power units, etc. In these applications, it can better balance system pressure and improve system stability and efficiency. -

5 Gallon (20 L) and 10 Gallon (40 L) Hydraulic Accumulators

These large-capacity accumulators are commonly used in heavy-duty hydraulic systems such as construction machinery, lifting equipment, and large manufacturing installations. They can store large amounts of energy and provide reliable backup power when the system needs it.

As a key component of the hydraulic system, the hydraulic bladder accumulator achieves efficient storage and release of energy by cleverly utilizing the interaction of gas and liquid. Its applications in energy balance, shock absorption, backup power, etc. make it an indispensable part of various engineering fields. By in-depth understanding of the principle and structure of hydraulic bladder accumulators, we can better understand its wide range of applications in different fields and provide strong support for engineering design and system optimization.