What is Gas Sensor?

A gas sensor is a device that is designed to detect the presence or concentration of gases in the surrounding environment. These sensors are widely used in various applications, including industrial processes, environmental monitoring, safety systems, and consumer electronics. Gas sensors work by responding to the physical or chemical changes that occur when a specific gas comes into contact with the sensor material. ATO industrial automation will introduce the basic information about the gas sensor for you.

How Does Gas Sensor Work

There are different types of gas sensors, and they operate based on various principles. These principles allow gas sensors to convert the presence of a specific gas into a measurable signal. The sensors can then provide real-time data on gas concentrations, enabling applications in safety, environmental monitoring, industrial processes, and more. The choice of the gas sensor depends on factors such as the type of gas to be detected, sensitivity, selectivity, response time, and environmental conditions. Here are some common types.

Chemical Gas Sensors:

- These sensors use a chemical reaction between the target gas and the sensing material.

- The reaction causes a change in the physical or chemical properties of the sensing material.

- Changes may include alterations in electrical conductivity, color, or other measurable parameters.

- The extent of the change is proportional to the concentration of the detected gas.

Electrochemical Gas Sensors:

- Electrochemical sensors have electrodes immersed in an electrolyte.

- A chemical reaction occurs at the electrodes when the target gas comes into contact with them.

- The reaction generates a current or voltage, which is proportional to the gas concentration.

- The electrical signal is then measured and converted into a gas concentration reading.

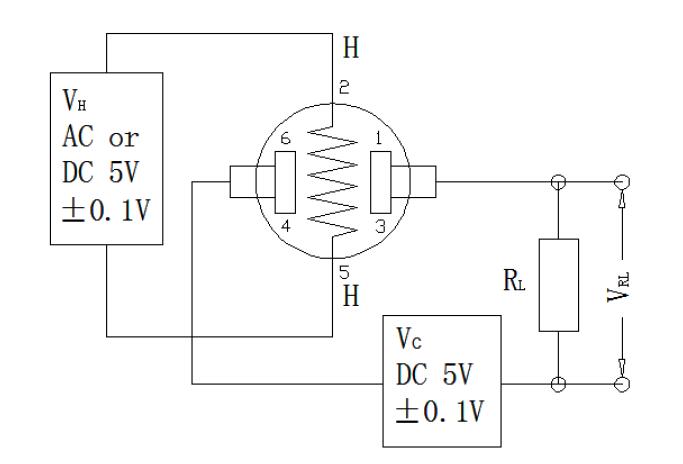

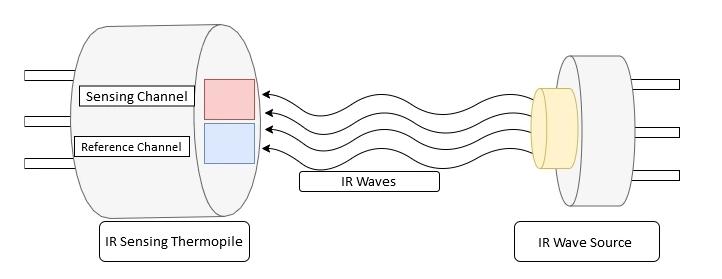

Infrared Gas Sensors:

- Infrared sensors use the principle that each gas absorbs infrared light at specific wavelengths.

- The sensor emits infrared light through a source.

- The target gas absorbs specific wavelengths of the emitted light, and the remaining light reaches a detector.

- The amount of absorbed light is proportional to the gas concentration and is used to calculate the gas concentration.

Catalytic Gas Sensors:

- Catalytic sensors are used for combustible gases.

- They contain a catalyst (often made of platinum) that promotes the combustion of the target gas.

- Combustion generates heat, and the resulting temperature change is measured.

- The heat produced is proportional to the gas concentration.

Photoionization Detectors (PID):

- PID sensors use ultraviolet (UV) light to ionize gas molecules.

- The ionization produces positively charged ions.

- The current generated by these ions is measured and used to determine the gas concentration.

- PID sensors are susceptible to volatile organic compounds (VOCs).

Structure of Gas Sensor

The structure of a gas sensor can vary based on its type and the specific technology used. However, a generic gas sensor often consists of common components designed to facilitate the detection of gases. Here is a generalized structure.

Sensing Element:

The sensing element is the core component responsible for interacting with the target gas. It could be a material that undergoes a change in its physical or chemical properties when exposed to the gas. The nature of the sensing element depends on the working principle of the gas sensor.

Electrodes:

In electrochemical gas sensors, electrodes are crucial components. These electrodes are immersed in an electrolyte, and their interaction with the target gas initiates a chemical reaction. The resulting current or voltage is measured and used to determine the gas concentration.

Catalyst (for Catalytic Sensors):

Catalytic gas sensors, designed to detect combustible gases, incorporate a catalyst (often made of materials like platinum). The catalyst promotes the combustion of the target gas, and the resulting heat change is measured.

Transducer:

The transducer converts the signal generated by the interaction between the sensing element and the target gas into an electrical signal. This signal can then be further processed and analyzed.

Housing/Enclosure:

The sensor is typically enclosed in a housing to protect it from external environmental factors and ensure stability in different conditions. The housing may also be designed to allow the diffusion of gases into the sensor.

Heater (for some types):

In certain gas sensors, especially those using metal oxide semiconductor technology, a heater may be present. The heater helps to maintain a consistent operating temperature, enhancing the sensor's stability and performance.

Optical Components (for Infrared Sensors):

Infrared gas sensors include optical components such as an infrared light source, a gas sample chamber, and a detector. The source emits infrared light, which interacts with the gas molecules in the sample chamber. The detector then measures the remaining light, allowing for gas concentration determination.

Microcontroller/Processing Unit:

In modern gas sensors, a microcontroller or processing unit may be integrated to handle signal processing, calibration, and communication with external devices or systems.

Output Interface:

Gas sensors typically have an output interface to communicate the detected gas concentrations. This could be an analog signal, a digital signal, or a communication protocol like I2C or UART.

Power Supply:

Gas sensors require a power supply to operate. The power supply may be integrated into the sensor or provided externally.

Advantage

Gas sensors offer several advantages, making them valuable in various applications. They enable the early detection of gas leaks, preventing accidents and ensuring the safety of people and property. Gas sensors play a crucial role in ensuring safety in environments where specific gases can be hazardous, commonly used in industrial settings, laboratories, and residential spaces. They are essential for monitoring and controlling air quality, helping to identify and mitigate pollution and environmental hazards.

In industries, gas sensors contribute to process control, monitoring, and optimizing various processes to ensure optimal conditions and efficiency. Providing real-time data, gas sensors allow for immediate response and intervention when gas concentrations exceed predefined thresholds. This contributes to energy efficiency in industrial processes by optimizing combustion and minimizing waste.

Gas sensors find applications in healthcare settings for monitoring anesthesia gases, and ensuring patient safety during medical procedures. Sensors designed to detect combustible gases are crucial for preventing fires and explosions, especially in industrial and residential settings. Photoionization Detectors (PID) are effective in detecting Volatile Organic Compounds (VOCs), which can be harmful to human health.

Gas sensors can be integrated into remote sensing systems, facilitating monitoring in hard-to-reach or hazardous locations. In smart building systems, gas sensors are incorporated to monitor indoor air quality and enhance energy efficiency by optimizing ventilation. They contribute to reducing the environmental impact of industrial activities by enabling efficient combustion processes and minimizing emissions.

The advantages of gas sensors also extend to cost savings, as early detection of gas leaks and efficient process control prevent accidents, minimize downtime, and optimize resource usage. With their versatility, gas sensors find applications in diverse fields, including industrial manufacturing, environmental monitoring, healthcare, transportation, and consumer electronics.

Overall, gas sensors play a crucial role in ensuring safety, protecting the environment, and optimizing various processes across different industries. Their versatility and ability to provide real-time data make them essential components in modern monitoring and control systems.